PZ production process applied to rubber foaming product

A production process and rubber foaming technology, which is applied in the field of synthesis of vulcanization accelerators, can solve the problems that PZ is difficult to obtain a stable shape, difficult to control the reaction rate, and reduce the vulcanization temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Take 1000mol of dimethylamine, 1200mol of carbon disulfide and 500mol of zinc oxide as raw materials, the quality of the material is calculated by the main component, first zinc oxide and carbon disulfide are added to the reaction kettle and mixed, and the solution in the reaction kettle is added dropwise with dimethylamine , the dripping acceleration rate is 50mol / min, the dripping temperature is controlled at 40 ℃, and the stirring rate is controlled at 80 r / min. After 4 hours of dripping, the temperature is raised to 80 ℃ to remove carbon disulfide, and the temperature is kept at 80 ℃ for 1 hour, and then the stirring rate is controlled at 80 ℃. 50r / min, cooling, filtration, dehydration to obtain PZ product.

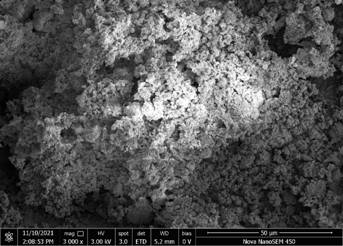

[0040] The morphology of the obtained PZ product is as follows figure 1 As shown, it showed agglomerated spherical shape and stable shape. The particle size of the obtained product is about 1um.

Embodiment 2

[0042] Take 1000mol of dimethylamine, 1200mol of carbon disulfide and 500mol of zinc oxide as raw materials, the quality of the material is calculated by the main component, first zinc oxide and carbon disulfide are added to the reaction kettle and mixed, and the solution in the reaction kettle is added dropwise with dimethylamine , the dripping acceleration rate is 50mol / min, the dripping temperature is controlled at 40 ℃, and the stirring rate is controlled at 65r / min. After 4 hours of dripping, the temperature is raised to 80 ℃ to remove carbon disulfide, and the temperature is kept at 80 ℃ for 1 hour, and then the stirring rate is controlled at 40r / min, cooling, filtering, dehydration,

[0043] Get PZ products.

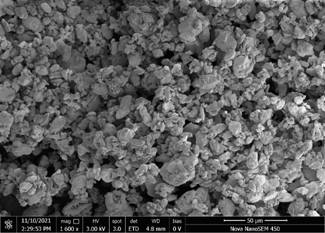

[0044] The morphology of the obtained PZ product is as follows figure 2 As shown, it is rod-shaped, and the particle size of the obtained product is about 5um.

Embodiment 3

[0050] In order to further verify the effect of PZ products in rubber and plastic foam materials, taking the prior art as an example, PZ was added as a vulcanization accelerator to the formula of rubber and plastic foam materials to verify the performance of the foam materials. The formula used is the formula of Example 3 of CN114133752A, wherein the vulcanization accelerator is an example.

[0051] CN 107200873 A discloses the formula: 100 parts of natural rubber NR, 30 parts of filler, 1 part of anti-aging agent, 2.5 parts of vulcanization agent, 2.5 parts of vulcanization accelerator, and 1 part of active agent. Wherein, the filler is carbon black; the vulcanizing agent is sulfur, the vulcanization accelerator is TMTM, CZ; the active agent is stearic acid.

[0052] The vulcanization accelerators used are PZ of Example 1, respectively, and the rest of the formulations remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com