Method for directly preparing carbon monoxide from coke-oxygen carrier

A carbon monoxide and oxygen carrier technology, applied in carbon monoxide, gasification process, molten salt/molten metal gasification, etc., can solve the problems of complex gas products, slow reaction rate, large demand, etc., and achieve good selectivity, low cost, Effect of reducing CO2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

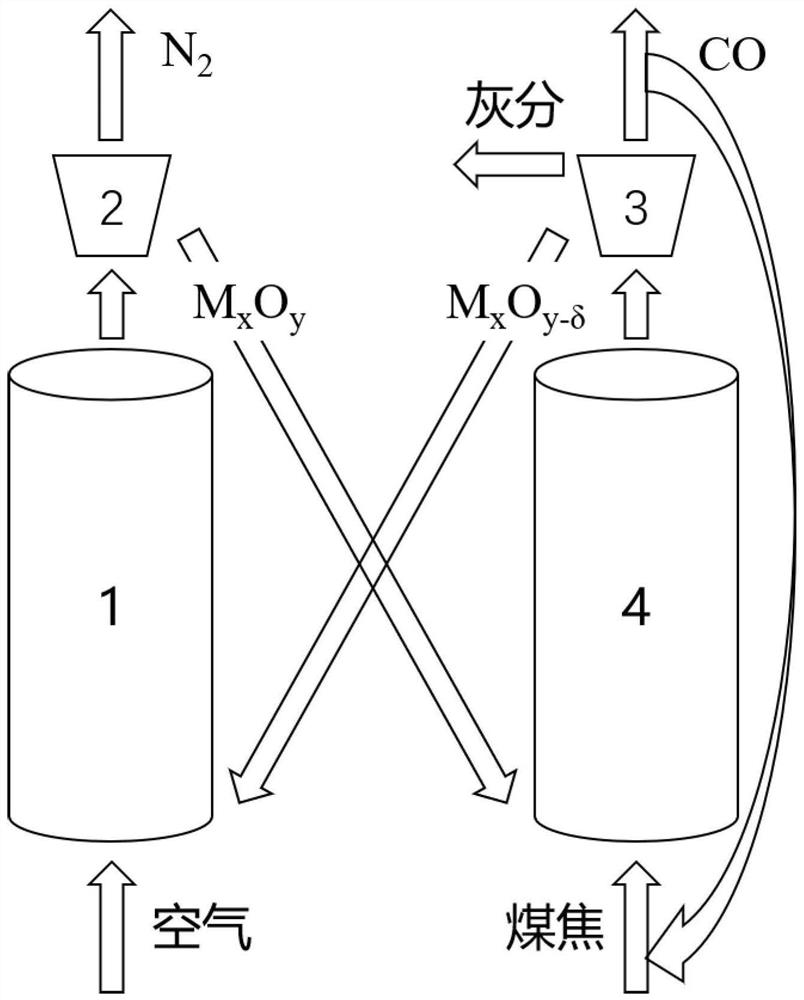

[0031] The preparation method of carbon monoxide specifically comprises the following steps:

[0032] S1. The char particles and the oxygen carrier particles are placed together at the bottom of the fuel reactor, and then the solid material is lifted to the top of the fuel reactor under the carrying of the fluidizing gas. During the lifting process, the lattice oxygen in the oxygen carrier Directly oxidize the coal char, then the coal char is oxidized under the action of the oxygen carrier to generate carbon monoxide and a small amount of carbon dioxide gas; then the gas product (where the carbon monoxide gas concentration is greater than 70%), the reacted oxygen carrier and a small amount of carbon dioxide gas are separated in the cyclone separator. ash;

[0033] S2. The reacted oxygen carrier separated by the cyclone is sent to the bottom of the air reactor, and the oxygen carrier is lifted to the top of the reactor under the driving of the air fluidizing gas, and the oxygen...

Embodiment 1

[0056] The temperature of the fuel reactor is 800°C, the temperature of the air reactor is 850°C, the mass ratio of coal char to oxygen carrier is 1:25, and the volatile content of coal char is 5%.

Embodiment 2

[0058] The temperature of the fuel reactor is 850°C, the temperature of the air reactor is 850°C, the mass ratio of coal char to oxygen carrier is 1:25, and the volatile content of coal char is 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap