Preparation method of rare earth element modified platinum ruthenium nanoparticles

A rare earth element and nanoparticle technology, applied in nanotechnology, nanotechnology, nanotechnology and other directions for materials and surface science, to achieve uniform particle size distribution, excellent HOR performance and stability, and simple and convenient synthesis methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

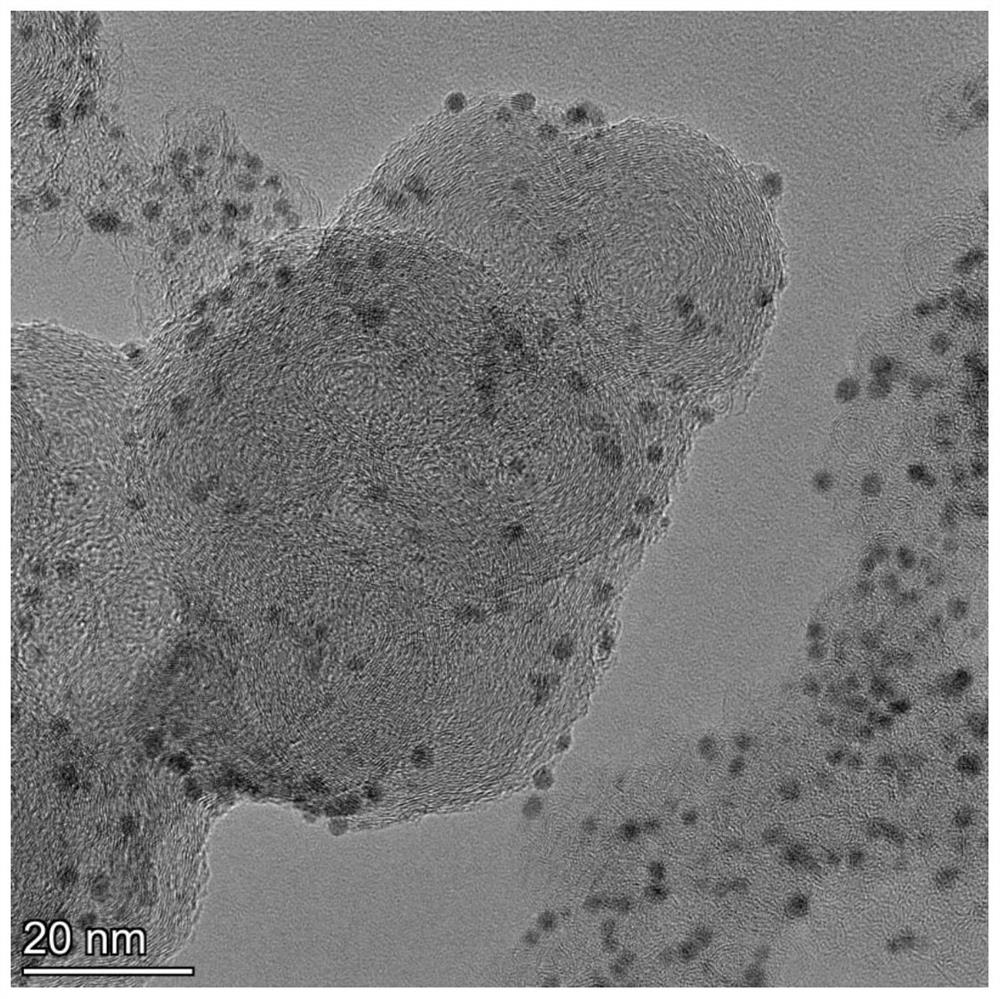

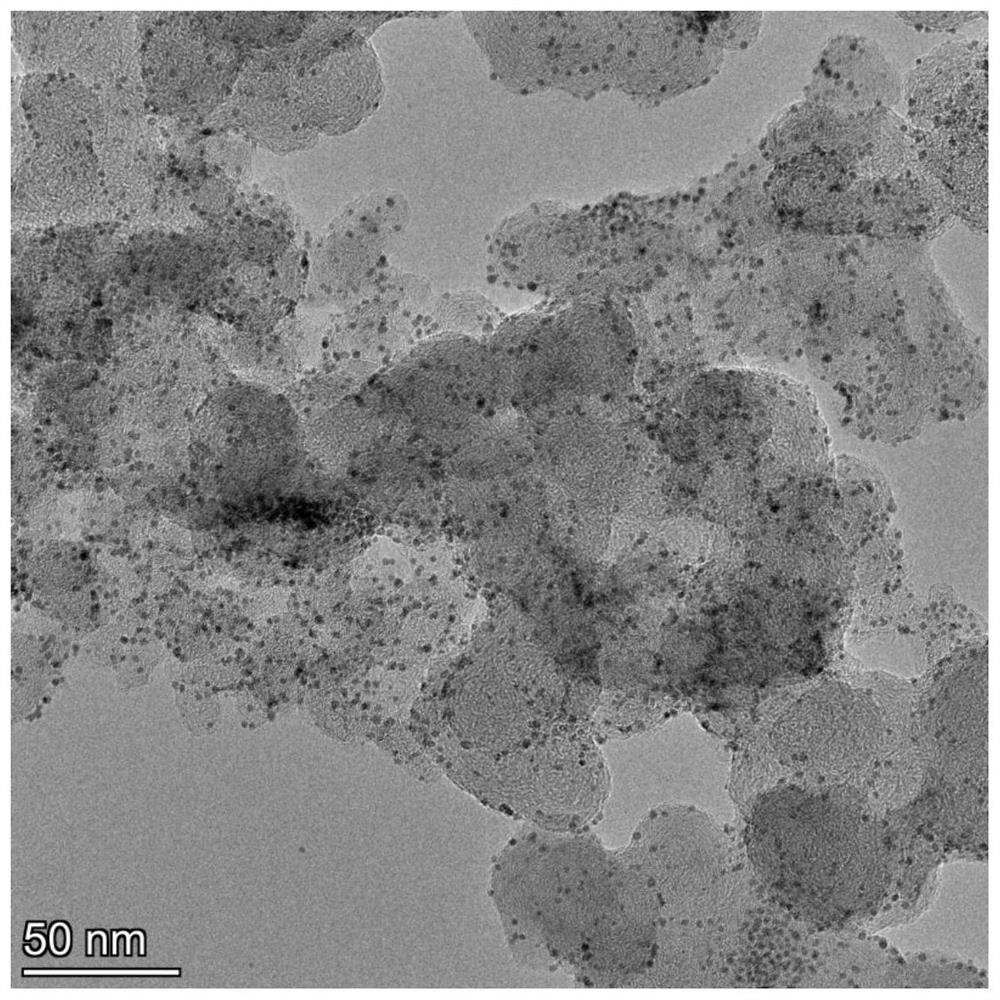

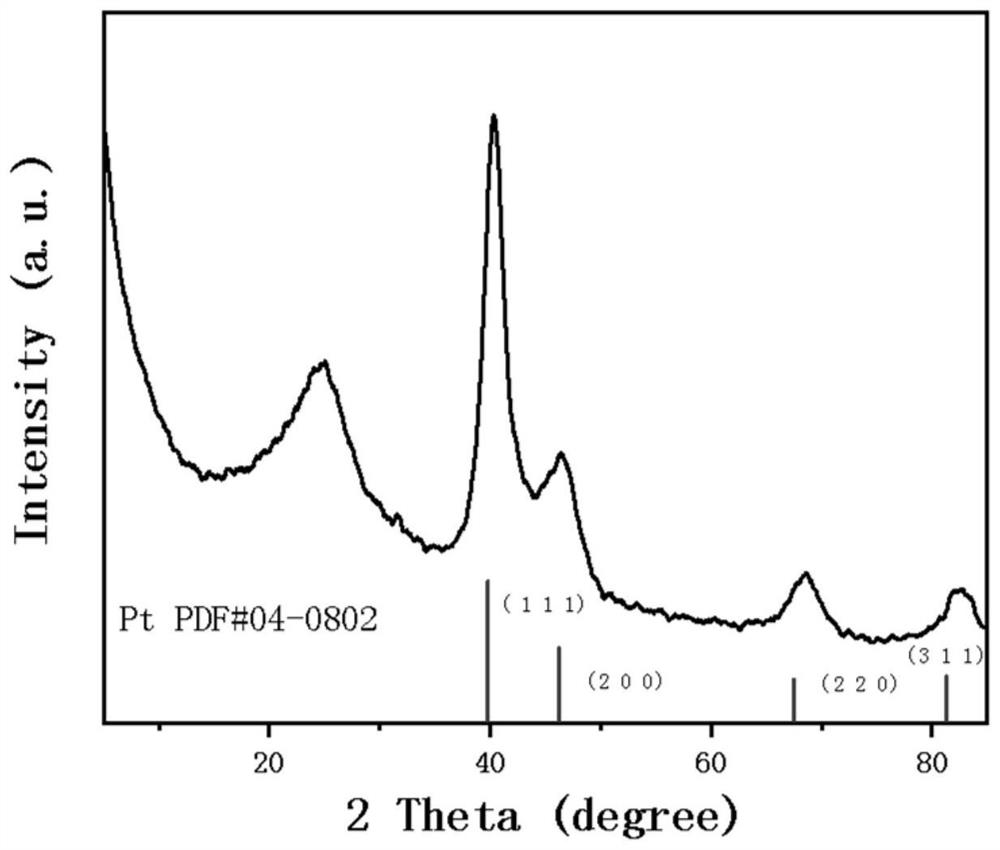

[0043] A preparation method of a rare-earth-modified PtRu nanoparticle catalyst with high performance and high stability under the simultaneous action of double reducing agents under alkaline conditions.

[0044] The method includes:

[0045] (1) get 0.2ml 10mMl / L erbium nitrate solution, 1ml 100mMl / L ruthenium chloride solution, 1ml 100mMl / L chloroplatinic acid solution, 0.5ml 10mg / ml sodium nitrate solution is mixed in 10ml DMF, stirs 30mMn at room temperature, The molar ratio of erbium ion, platinum ion and ruthenium ion in the mixed solution is 0.02:1:1;

[0046] (2) Add 26mg of sodium borohydride, stir 20mMn, then pass hydrogen into the quartz tube to make the pressure in the quartz tube 0.3MpM, make the reaction react at 150 ° C for 3 hours, cool to room temperature, wash with acetone for 3 times, and dry for 6 hours Obtain erbium-modified ruthenium platinum nanoparticles;

[0047] (3) Mixing the obtained catalyst and carbon black uniformly, after ultrasonication, dryi...

Embodiment 2

[0049] All the other are the same as in Example 1, except that erbium nitrate is changed into europium nitrate to obtain Pt 1 Ru 1 -EuO x / C.

Embodiment 3

[0051] All the other are the same as in Example 1, except that erbium nitrate is changed into cerium nitrate to obtain Pt 1 Ru 1 -CeO x / C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com