TPU (Thermoplastic Polyurethane) film for garment hot stamping and production process thereof

A production process and garment technology, applied in the field of TPU film for garment hot stamping and its production process, to achieve the effect of enhancing peel strength and avoiding quality and health problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

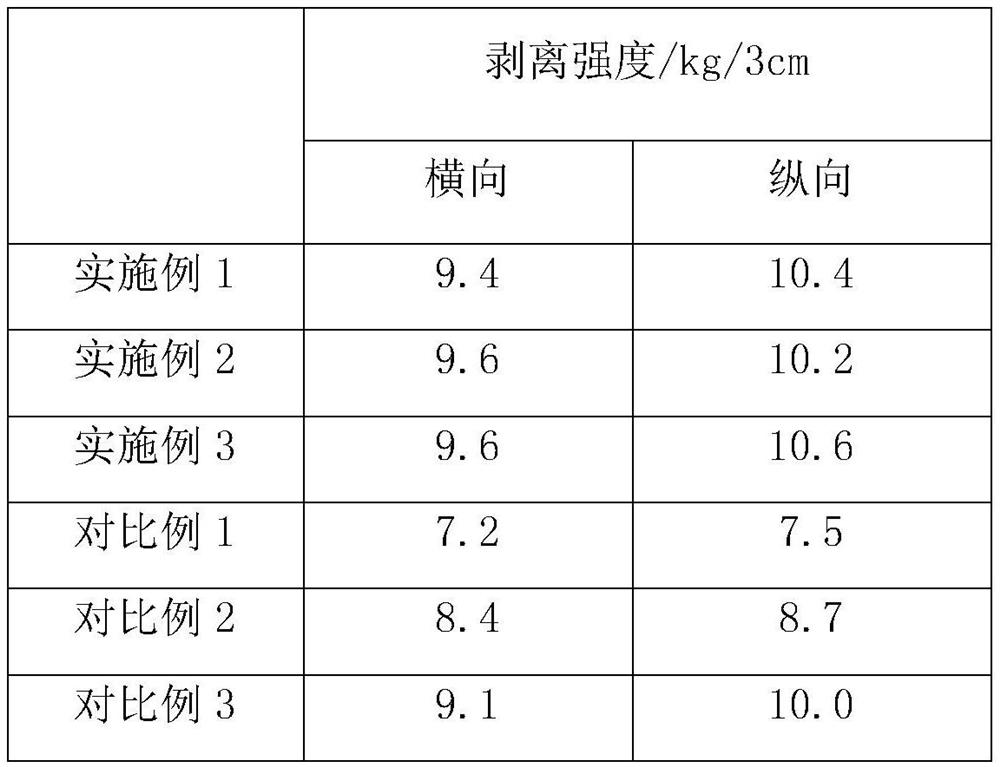

Examples

Embodiment 1

[0023] The present embodiment provides a production process of a TPU film for garment hot stamping, comprising the following steps:

[0024] S1. Preparation of TPU base: Coat a high-melting TPU film with a melting point of 180°C on a high-melting point TPU film with a melting point of 100°C. The melted liquid hot-melt adhesive of the low-melting TPU particles, after cooling, compound the PE protective film, and wind it up for use.

[0025] S2. Preparation of dry surface layer: coating the surface layer PU slurry on the surface of the release paper, the coating amount is 120g / m 2 , the viscosity at 20 ° C is 3000cps, then dried at 125 ° C until the solvent is completely volatilized, and rolled for use; the surface layer PU slurry is composed of the following components in parts by weight: 40 parts of solvent, 40 parts of polyurethane resin LT -95 100 parts, 5 parts of color paste, the solvent is DMF.

[0026] S3, extrusion compounding: unwinding the TPU base, coating 20g / m aft...

Embodiment 2

[0030] The present embodiment provides a production process of a TPU film for garment hot stamping, comprising the following steps:

[0031] S1. Preparation of TPU base: Coat a high-melting point TPU film with a melting point of 160°C on a high-melting point TPU film with a melting point of 95°C. The liquid hot melt adhesive after melting of the low-melting point TPU particles, after cooling, compound the PE protective film, and wind it up for use.

[0032] S2. Preparation of dry surface layer: coating the surface layer PU slurry on the surface of the release paper, the coating amount is 150g / m 2 , the viscosity at 20°C is 3000cps, and then dried at 120°C until the solvent is completely volatilized, and the roll is ready for use; the surface layer PU slurry is composed of the following components in parts by weight: 30 parts of DMF, 20 parts of MEK, polyurethane 120 parts of resin LT-95, 8 parts of color paste.

[0033] S3, extrusion compounding: unwinding the TPU base, coati...

Embodiment 3

[0037] The present embodiment provides a production process of a TPU film for garment hot stamping, comprising the following steps:

[0038] S1. Preparation of TPU base: Coat a high melting point TPU film with a melting point of 175°C on a high melting point TPU film with a melting point of 105°C. The melted liquid hot-melt adhesive of the low melting point TPU particles, after cooling, compound the PE protective film, and wind it up for use.

[0039] S2. Preparation of dry surface layer: coating the surface layer PU slurry on the surface of the release paper, the coating amount is 100g / m 2 , the viscosity at 20 ° C is 2500cps, then dried at 130 ° C until the solvent is completely volatilized, and the roll is ready for use; the surface layer PU slurry is composed of the following components in parts by weight: 30 parts of solvent, 30 parts of polyurethane resin LT -95 100 parts, color paste 4 parts, the solvent is MEK.

[0040] S3, extrusion compounding: unwinding the TPU bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com