Wave-absorbing material, preparation method thereof and stealth device

A technology of wave-absorbing material and wave-absorbing coating, which is applied in wave-absorbing material, stealth device, and its preparation field, and can solve the problems of high magnetic permeability and low dielectric constant, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] As described in the background art, the existing wave absorbing materials cannot simultaneously meet the performance requirements of wave absorbing materials with high magnetic permeability, low dielectric constant, good matching, strong absorption performance, and good corrosion resistance and oxidation resistance at low frequencies. In order to solve the above-mentioned technical problems, the present application provides a preparation method of a wave absorbing material, and the preparation method of the wave absorbing material comprises: mixing a solution containing ferric ions and barium ions with flaky carbonyl iron powder to obtain a reaction solution; A pH regulator is used to adjust the pH of the reaction solution to 8-10, so that a precipitation reaction occurs to obtain a precipitation product; and the precipitation product is dried to obtain a wave absorbing material.

[0024] Through the above preparation method, a wave absorbing material composited with fla...

Embodiment 1

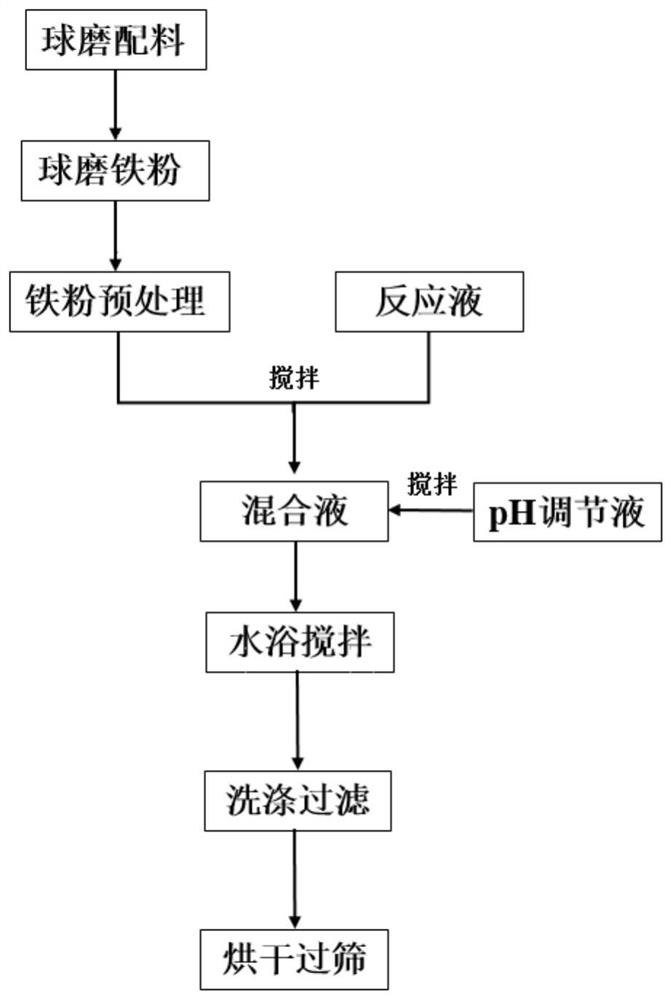

[0045] A method for preparing flaky carbonyl iron powder coated with low-frequency flaky hexagonal ferrite, the technological process is as follows figure 1 shown, including the following steps:

[0046] 1. Preparation of flake carbonyl iron powder

[0047] Add 200 parts of spherical carbonyl iron powder to 500 parts of anhydrous ethanol, stir evenly, put it into a horizontal planetary ball mill for wet ball milling, the ball milling speed is 400r / min, and the ball milling time is 15h; The mass ratio of the agate beads and carbonyl iron powder used in the ball milling is 10:4. The agate beads are composed of large, medium and small agate beads with diameters of 10mm, 6mm and 3mm. The mass ratio of the large, medium and small agate beads is 5:25:70. After the ball milling, the slurry was taken out and dried at 40 °C for 12 h to obtain flat carbonyl iron powder.

[0048] 2. Pretreatment of carbonyl iron powder

[0049] Add 100 parts of flaky carbonyl iron powder to 5% dilute...

Embodiment 2

[0055] A method for preparing flaky carbonyl iron powder coated with low-frequency flaky hexagonal ferrite, comprising the following steps:

[0056] 1. Preparation of flake carbonyl iron powder

[0057] Add 200 parts of spherical carbonyl iron powder to 500 parts of anhydrous ethanol, stir evenly, put it into a horizontal planetary ball mill for wet ball milling, the ball milling speed is 400r / min, and the ball milling time is 15h; The mass ratio of the agate beads and carbonyl iron powder used in the ball milling is 10:4. The agate beads are composed of large, medium and small agate beads with diameters of 10mm, 6mm and 3mm. The mass ratio of the large, medium and small agate beads is 5:25:70. After the ball milling, the slurry was taken out and dried at 40 °C for 12 h to obtain flat carbonyl iron powder.

[0058] 2. Pretreatment of carbonyl iron powder

[0059] Add 100 parts of flaky carbonyl iron powder to 5% dilute hydrochloric acid for sonication for 4 minutes, place t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com