Antibacterial composition, preparation method and application thereof, antibacterial chopping board and manufacturing method of antibacterial chopping board

An antibacterial composition and cutting board technology, applied in the field of antibacterial composition and its preparation, application, antibacterial cutting board and its production, can solve the problems of poor antibacterial performance and bactericidal performance, poor mold resistance, poor wear resistance, etc., to achieve excellent antibacterial Effect, high-efficiency antibacterial performance, strong and wear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

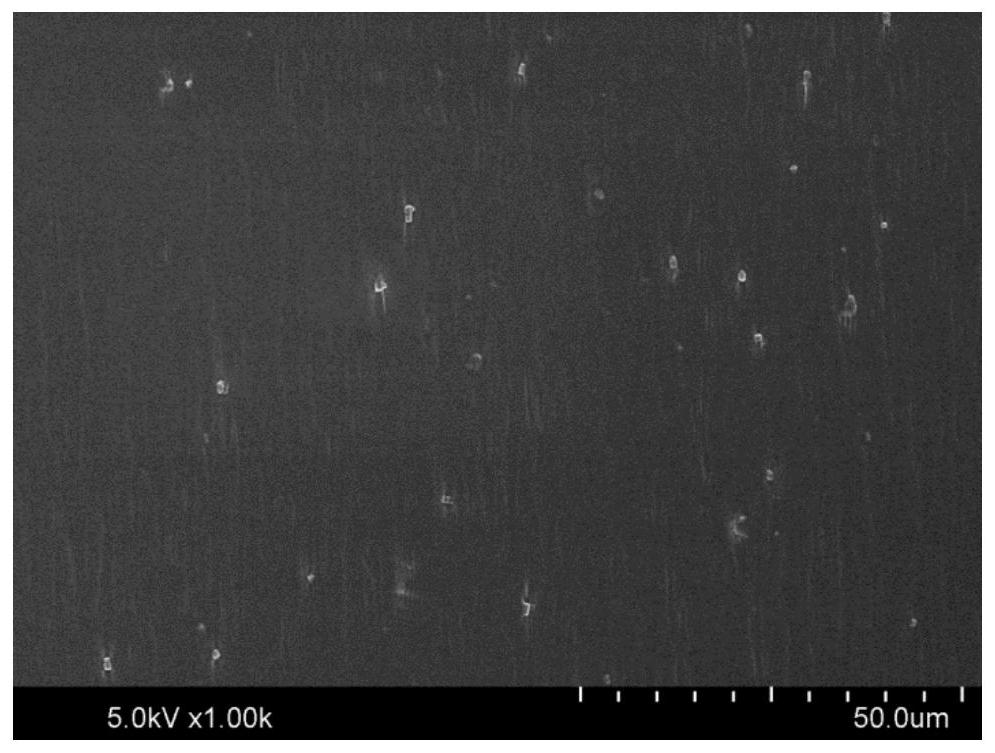

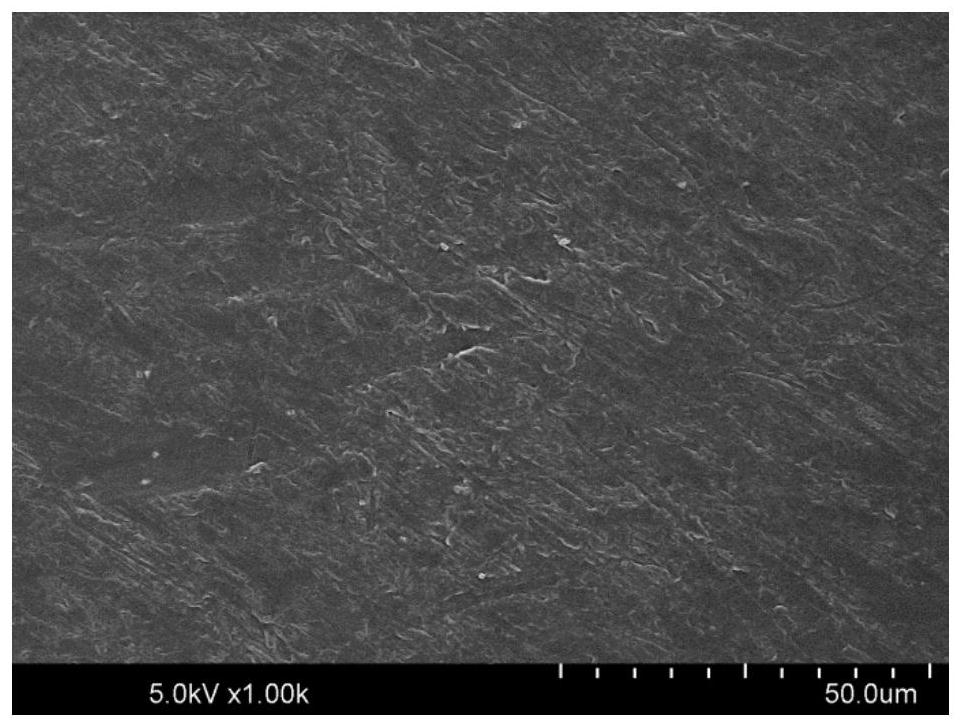

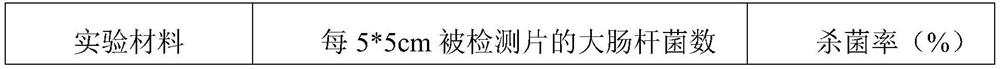

Image

Examples

Embodiment 1

[0056] (1) Preparation of antibacterial composition: according to the mass ratio of 77% melamine resin, 21% glass fiber, 2% zirconium phosphate silver-loaded antibacterial agent, weigh the corresponding raw materials, and mix them uniformly by a stirring device to obtain a mixed material. Add it to a twin-screw extruder, and melt and extrude it at a temperature of 200°C to obtain an antibacterial composition;

[0057] (2) preparation of antibacterial chopping board: the antibacterial composition and resin in step (1) are sent into the mold for preparing chopping board together according to the mass ratio of 10:90 for extrusion molding, and the chopping board carcass is obtained through demoulding; The carcass was finely ground and polished to obtain a finished chopping block; the temperature and pressure in the mold were 71° C. and 68.9 MPa, respectively.

Embodiment 2

[0059] (1) Preparation of the antibacterial composition: according to the mass ratio of 68.6% syndiotactic polystyrene resin, 29% glass fiber, 2.4% zirconium phosphate silver-loaded antibacterial agent, weigh the corresponding raw materials, and mix them uniformly by a stirring device to obtain a mixed material, adding the mixed material to a twin-screw extruder, and melt extrusion at a temperature of 300°C to obtain an antibacterial composition;

[0060] (2) preparation of antibacterial chopping board: the antibacterial composition and resin in step (1) are sent into the mold for preparing chopping board together according to the mass ratio of 50:50 for extrusion molding, and the chopping board carcass is obtained through demoulding; The carcass was finely ground and polished to obtain a finished cutting board; the temperature and pressure in the mold were 149° C. and 103 MPa, respectively.

Embodiment 3

[0062] (1) Preparation of antibacterial composition: Weigh the corresponding raw materials according to the mass ratio of 78% syndiotactic polystyrene resin, 20.9% glass fiber, and 1.1% zirconium phosphate silver-loaded antibacterial agent, and mix them uniformly by a stirring device to obtain Mixing the material, adding the mixed material to a twin-screw extruder, and melting and extruding at a temperature of 180° C. to obtain an antibacterial composition;

[0063] (2) preparation of antibacterial chopping board: the antibacterial composition and resin in step (1) are sent into the mold for preparing chopping board together according to the ratio of mass ratio of 80:20 for extrusion molding, and the chopping board carcass is obtained through demoulding; The carcass is finely ground and polished to obtain a finished cutting board; wherein the temperature and pressure in the mold are 89° C. and 80 MPa, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com