Combined heat and power generation device and method based on carbon dioxide conversion and utilization

A carbon dioxide, cogeneration technology, applied in steam engine installations, oxygen production, steam application, etc., can solve the problems of difficult carbon dioxide gas disposal, high carbon capture cost, greenhouse effect, etc., to improve comprehensive energy utilization efficiency and product quality. Excellent, high economic value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

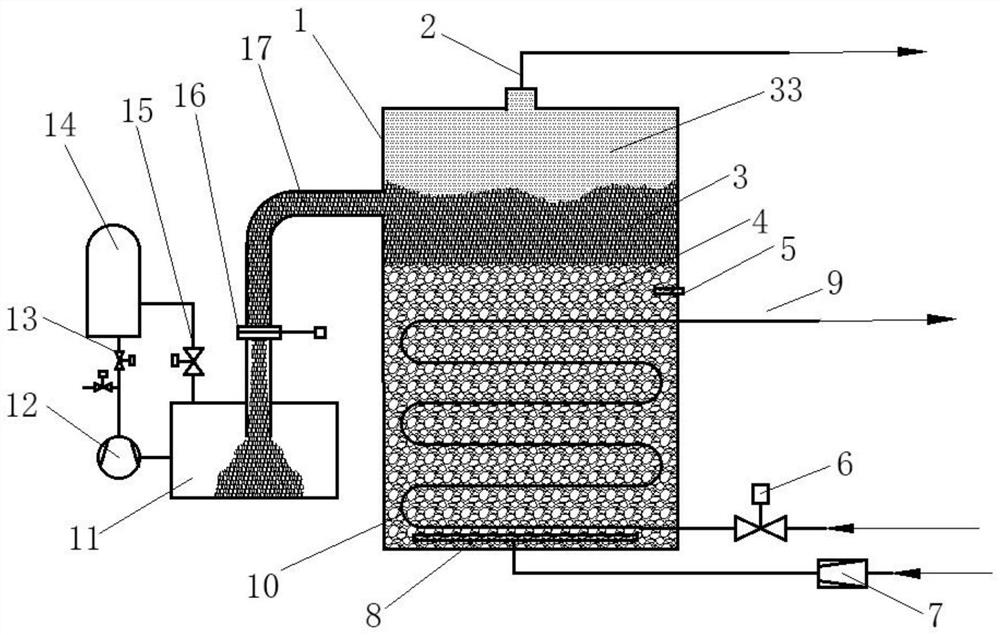

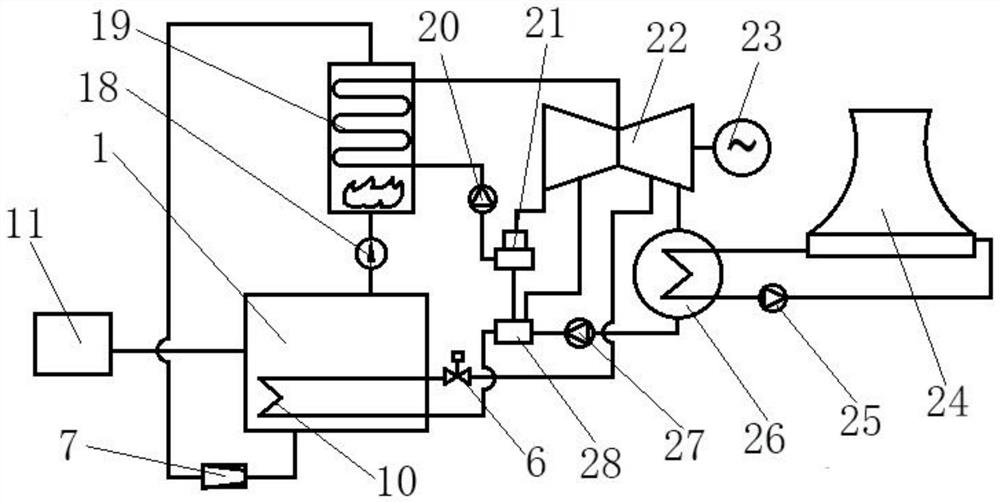

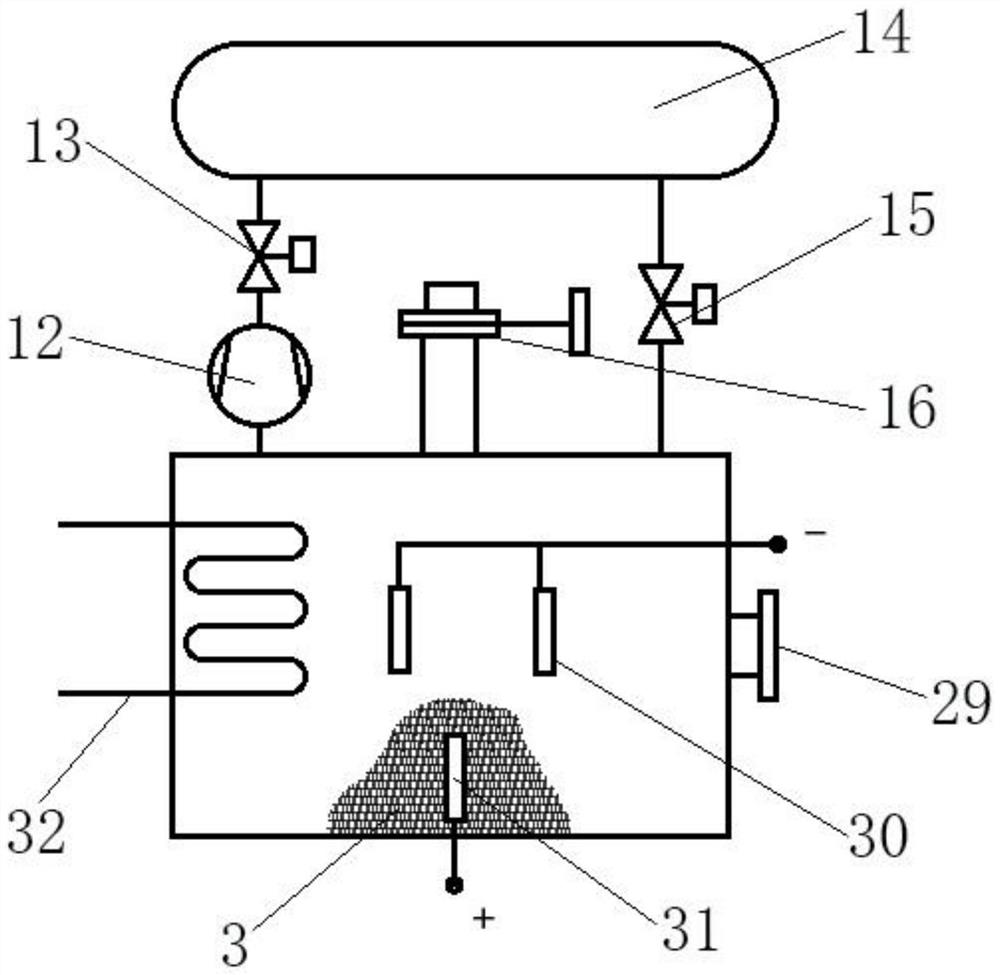

[0021] like Figure 1 to Figure 3 As shown, a cogeneration device and method based on carbon dioxide conversion and utilization, comprising a reactor 1, an oxygen delivery pipeline 2, a carbon sheet 3, a liquid alloy 4, a temperature probe 5, a steam flow control valve 6, a carbon dioxide compression device 7, Carbon dioxide distributor 8, steam pipeline 9, heater 10, carbon sheet reaction box 11, air compressor 12, pressure relief valve 13, pressure balance tank 14, pressure balance valve 15, closing valve 16, carbon sheet conveying pipeline 17, oxygen Conveyor 18, boiler 19, booster pump 20, deaerator 21, steam turbine 22, generator set 23, cooling tower 24, condensate circulating pump 25, condenser 26, condensate transfer pump 27, condensate heating device 28, The material taking port 29 , the negative electrode arc rod 30 , the positive elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com