Preparation method of silk fibroin repair patch and silk fibroin repair patch

A silk fibroin and patch technology, applied in the field of tissue repair materials, can solve problems such as the difficulty in making silk fibroin repair patches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

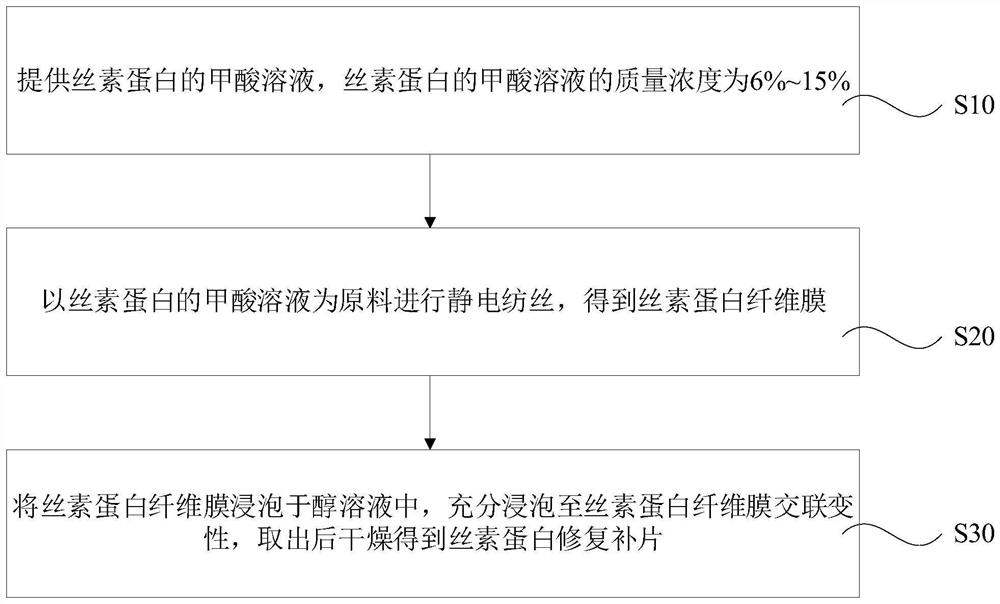

[0036] like figure 1 The preparation method of the silk fibroin repair patch of one embodiment shown, comprises the following steps:

[0037] S10, providing a formic acid solution of silk fibroin, and the mass concentration of the formic acid solution of silk fibroin is 6%-15%.

[0038] In this embodiment, formic acid is used as a solvent for silk fibroin, and formic acid is a volatile substance, so as to ensure that the finally prepared silk fibroin repair patch does not contain toxic substances.

[0039] In the present invention, the control of the mass concentration of the formic acid solution of silk fibroin is extremely important. If the concentration is too low, microspheres and beads are likely to appear, which will affect the performance of the silk fibroin repair patch. Electrospinning.

[0040] More preferably, the mass concentration of the formic acid solution of silk fibroin is 10%.

[0041] Preferably, in this embodiment, the formic acid solution of silk fibroi...

Embodiment 1

[0073] Weigh the silkworm cocoon (Sichuan Silkworm No. 26), cut it into pieces, wash it three times with ultrapure water to remove impurities, and prepare 0.02M Na 2 CO 3 solution and heat to boil, add silkworm cocoon fragments to the boiling Na 2 CO 3 solution, boil for 30min, repeat 3 times. Next, the silkworm cocoons were soaked in ultrapure water at 60°C, stirred and washed, washed for 30 minutes, and repeated 3 times. Finally, the silkworm cocoons were placed in an oven at 40°C overnight, and dried to obtain silk fibroin.

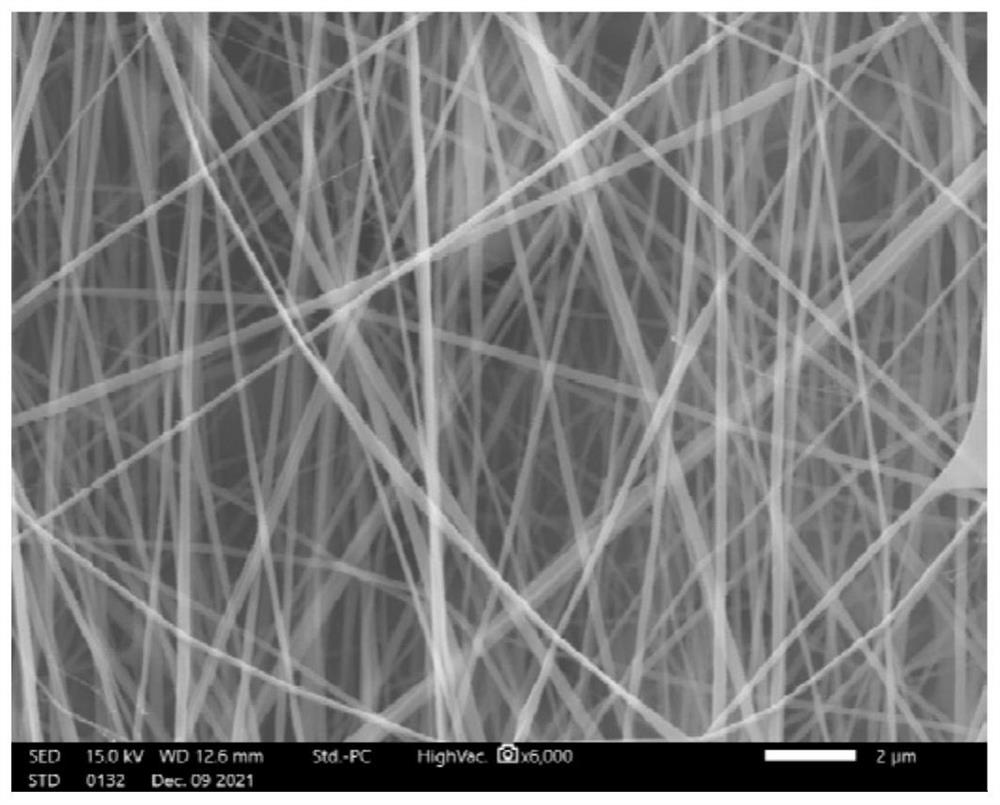

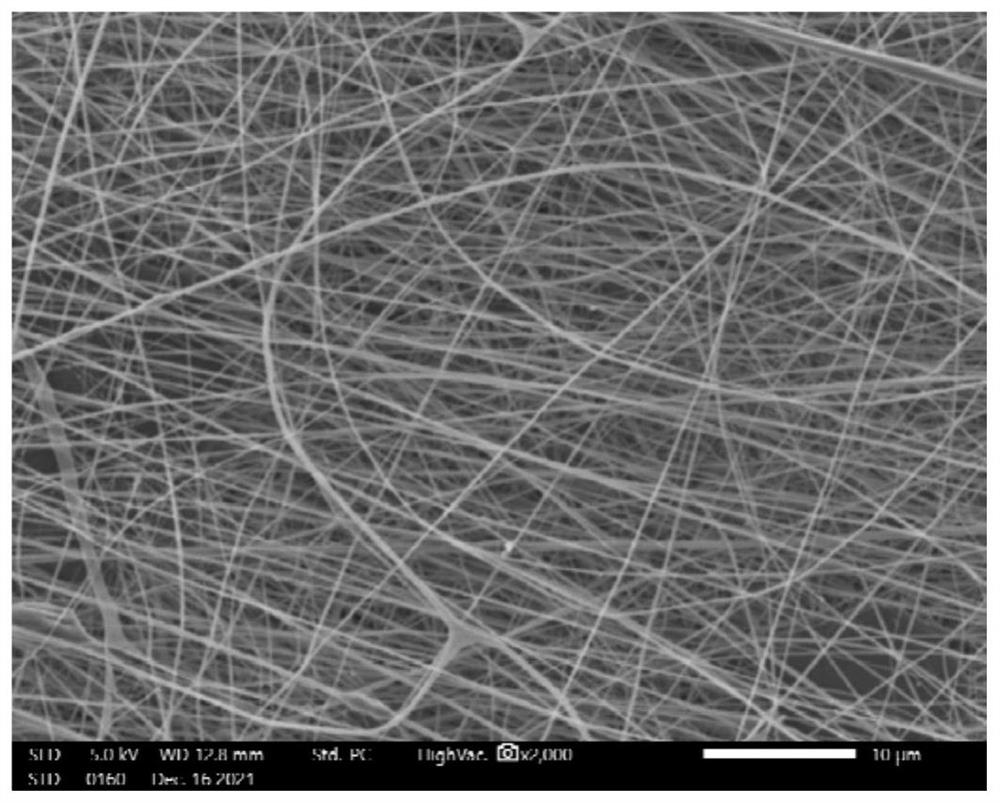

[0074] According to the solid-liquid ratio of 1:4, the silk fibroin was dissolved in a LiBr solution with a concentration of 9.3 mol / L to obtain a mixed solution. The mixed solution was transferred to a dialysis bag with a molecular weight cut-off of 8000, and then the dialysis bag was placed in Dialysis was performed in ultrapure water. After the dialysis was completed, the liquid in the dialysis bag was centrifuged, and the supernatant was retaine...

Embodiment 2

[0078] Weigh the silkworm cocoon (Sichuan Silkworm No. 26), cut it into pieces, wash it three times with ultrapure water to remove impurities, and prepare 0.02M Na 2 CO 3 solution and heat to boil, add silkworm cocoon fragments to the boiling Na 2 CO 3 solution, boil for 30min, repeat 3 times. Next, the silkworm cocoons were soaked in ultrapure water at 60°C, stirred and washed, washed for 30 minutes, and repeated 3 times. Finally, the silkworm cocoons were placed in an oven at 40°C overnight, and dried to obtain silk fibroin.

[0079] According to the solid-liquid ratio of 1:4, the silk fibroin was dissolved in a LiBr solution with a concentration of 9.3 mol / L to obtain a mixed solution. The mixed solution was transferred to a dialysis bag with a molecular weight cut-off of 8000, and then the dialysis bag was placed in Dialysis was performed in ultrapure water. After the dialysis was completed, the liquid in the dialysis bag was centrifuged, and the supernatant was retaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com