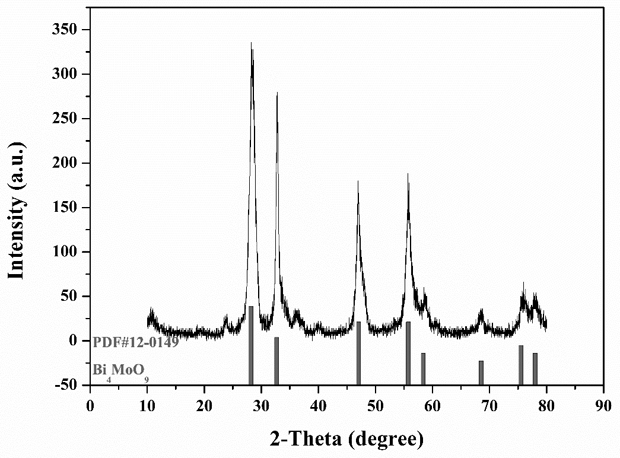

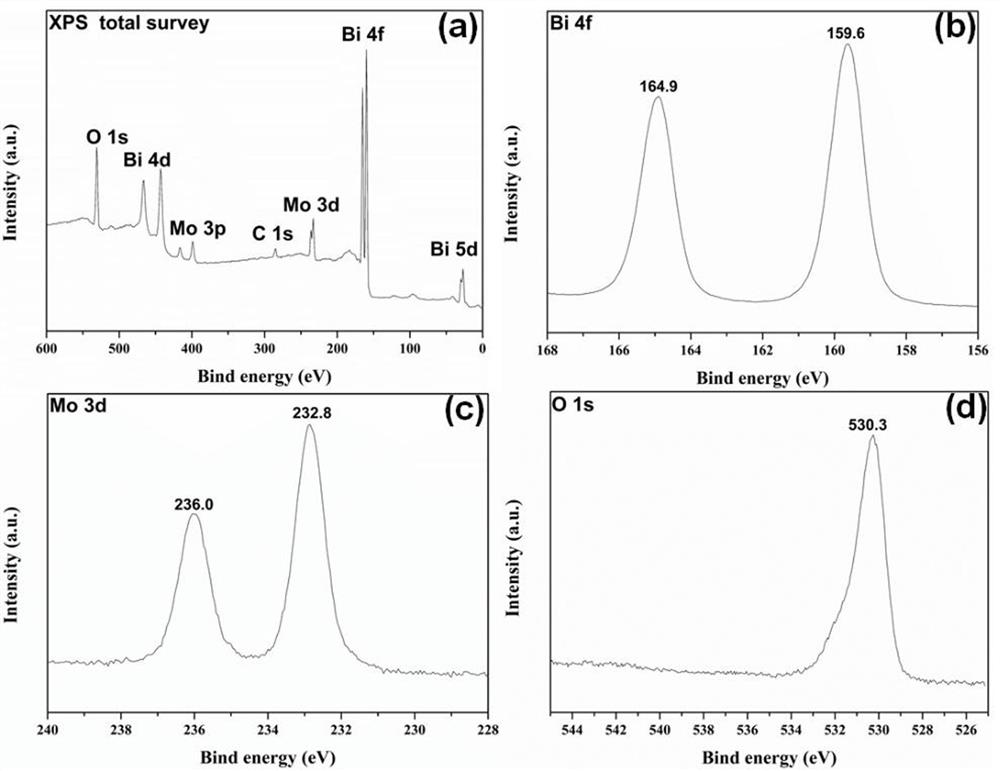

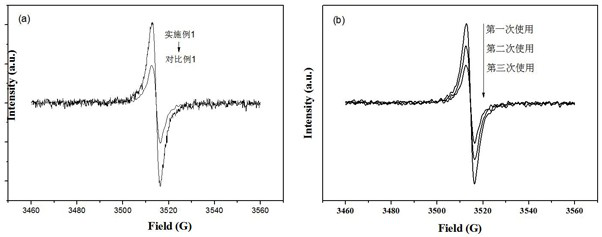

Oxygen vacancy-enriched bismuth molybdate photocatalytic material as well as preparation method and application thereof

A photocatalytic material, bismuth molybdate technology, applied in the field of photocatalysis, can solve the problems of limited optimization and achieve the effect of increasing content, improving separation efficiency and high degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) 0.5 mmol Bi(NO 3 ) 3 · 5H 2 O was dissolved in 60 ml of deionized water, 1.5 mmol of sodium dodecylbenzenesulfonate was added under constant stirring for 1 h, and then 0.5 mmol of NH was added. 4 VO 3 Dissolved in 60ml of water and stirred for 30min; finally, the above solution was mixed and stirred for 30min to form a stable precursor solution A;

[0031] (2) 6 mmol of Bi(NO 3 ) 3 · 5H 2 O was dissolved in 60 ml of 1 mol / L nitric acid to form solution I, and 3 mmol of Na 2 MoO 4 ·2H 2 O is dissolved in 60ml, 1mol / L of sodium hydroxide to form solution II; 6mmol of citric acid is added to solution I; then solution I mixed with citric acid is mixed with solution II to form stable precursor solution B;

[0032] (3) Adjust the pH of solutions A and B to 7, respectively, and let stand for 2 hours; then mix solutions A and B and transfer them to a hydrothermal reactor, and react at 160 °C for 24 hours;

[0033] (4) After the reaction kettle was cooled, the solu...

Embodiment 2

[0035] (1) 0.5 mmol Bi(NO 3 ) 3 · 5H 2 O was dissolved in 60 ml of deionized water, 1.5 mmol of sodium dodecylbenzenesulfonate was added under constant stirring for 1 h, and then 0.5 mmol of NH was added. 4 VO 3 Dissolved in 60ml of water and stirred for 30min; finally, the above solution was mixed and stirred for 30min to form a stable precursor solution A;

[0036] (2) 6 mmol of Bi(NO 3) 3 · 5H 2 O was dissolved in 65 ml of 1 mol / L nitric acid to form solution I, and 3 mmol of Na 2 MoO 4 ·2H 2 O is dissolved in 65ml, 1mol / L of sodium hydroxide to form solution II; 6.5mmol of citric acid is added to solution I; then solution I mixed with citric acid is mixed with solution II to form stable precursor solution B;

[0037] (3) Adjust the pH of the solutions A and B to 7 respectively, and let them stand for 1.5 hours; then mix the solutions A and B and transfer them to the hydrothermal reactor, and react at 160°C for 24 hours;

[0038] (4) After the reaction kettle was ...

Embodiment 3

[0040] (1) 0.5 mmol Bi(NO 3 ) 3 · 5H 2 O was dissolved in 60 ml of deionized water, 1.5 mmol of sodium dodecylbenzenesulfonate was added under constant stirring for 1 h, and then 0.5 mmol of NH was added. 4 VO 3 Dissolved in 60ml of water and stirred for 30min; finally, the above solution was mixed and stirred for 30min to form a stable precursor solution A;

[0041] (2) 6 mmol of Bi(NO 3 ) 3 · 5H 2 O was dissolved in 55 ml of 1 mol / L nitric acid to form solution I, and 3 mmol of Na 2 MoO 4 ·2H 2 O is dissolved in 55ml, 1mol / L of sodium hydroxide to form solution II; 5.5mmol of citric acid is added to solution I; then solution I mixed with citric acid is mixed with solution II to form stable precursor solution B;

[0042] (3) Adjust the pH of solutions A and B to 7, respectively, and let stand for 2.5 hours; then mix solutions A and B and transfer them to a hydrothermal reactor, and react at 160 °C for 24 hours;

[0043] (4) After the reaction kettle was cooled, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com