Preparation method of impermeable geomembrane

A geomembrane and geotextile technology, applied in flat products, biochemical fiber treatment, application, etc., can solve the problem of low reaction efficiency, and achieve the effect of improving the diffusion range, promoting the generation of bubbles, and promoting the effect of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

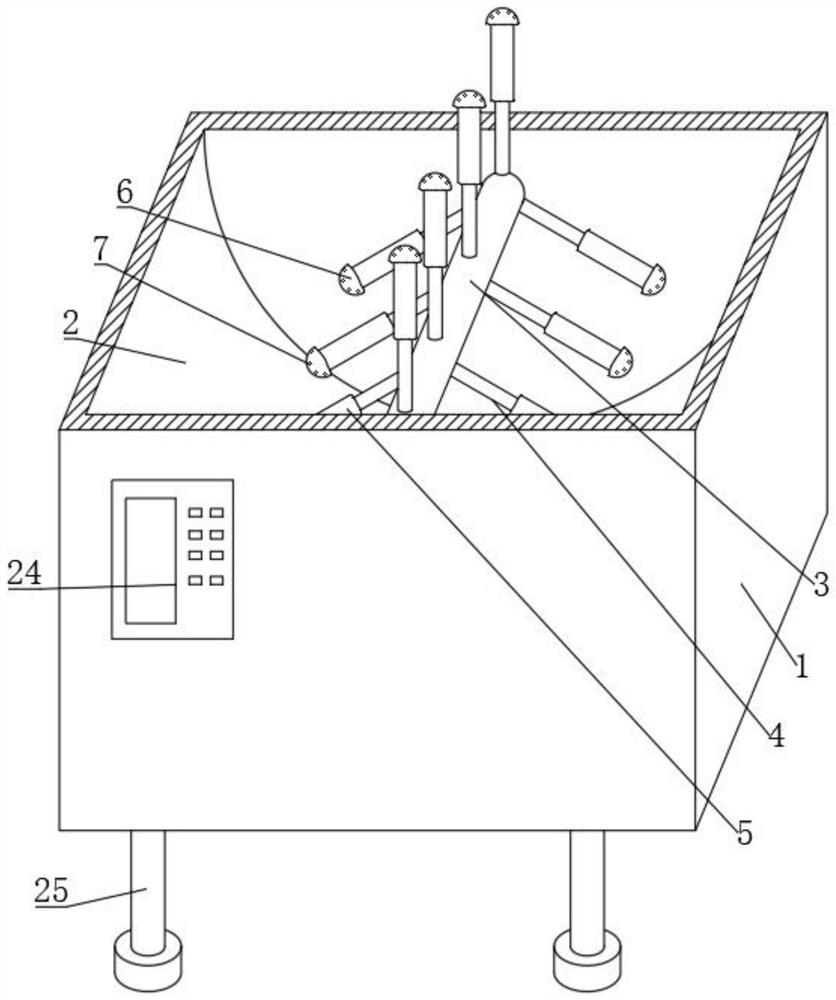

[0041] refer to Figure 1-3 , an anti-seepage geomembrane preparation method, specifically comprising the following steps:

[0042] S1, adding polyacrylonitrile fiber and sodium hydroxide solution in a mass ratio of 1:3 into the reaction kettle and mixing, and filtering after stirring to obtain alkalized polyacrylonitrile fiber;

[0043] S2. Mix the alkalized polyacrylonitrile fiber and the activated bagasse in a mass ratio of 8:1, and add a catalyst with a mass of 0.3 times the polyacrylonitrile fiber. After stirring and reacting, filter, wash, dry, and cut to obtain modified polypropylene. Acrylic fiber;

[0044] S3. Mix polypropylene fiber and modified polyacrylonitrile fiber to loosen, weave mesh, and acupuncture to obtain acupuncture polypropylene geotextile;

[0045] S4, soak the acupuncture polypropylene geotextile in the Bacillus subtilis bacterial solution, take it out, and obtain the pretreated acupuncture polypropylene geotextile;

[0046] S5. Soak the pretreated...

Embodiment 2

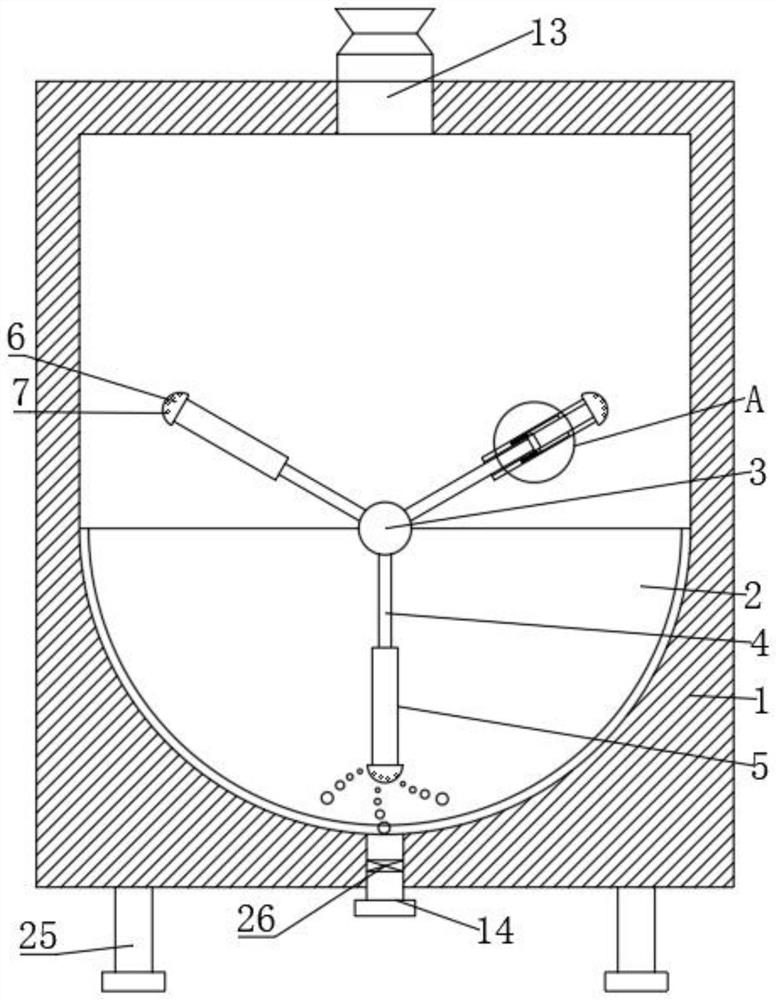

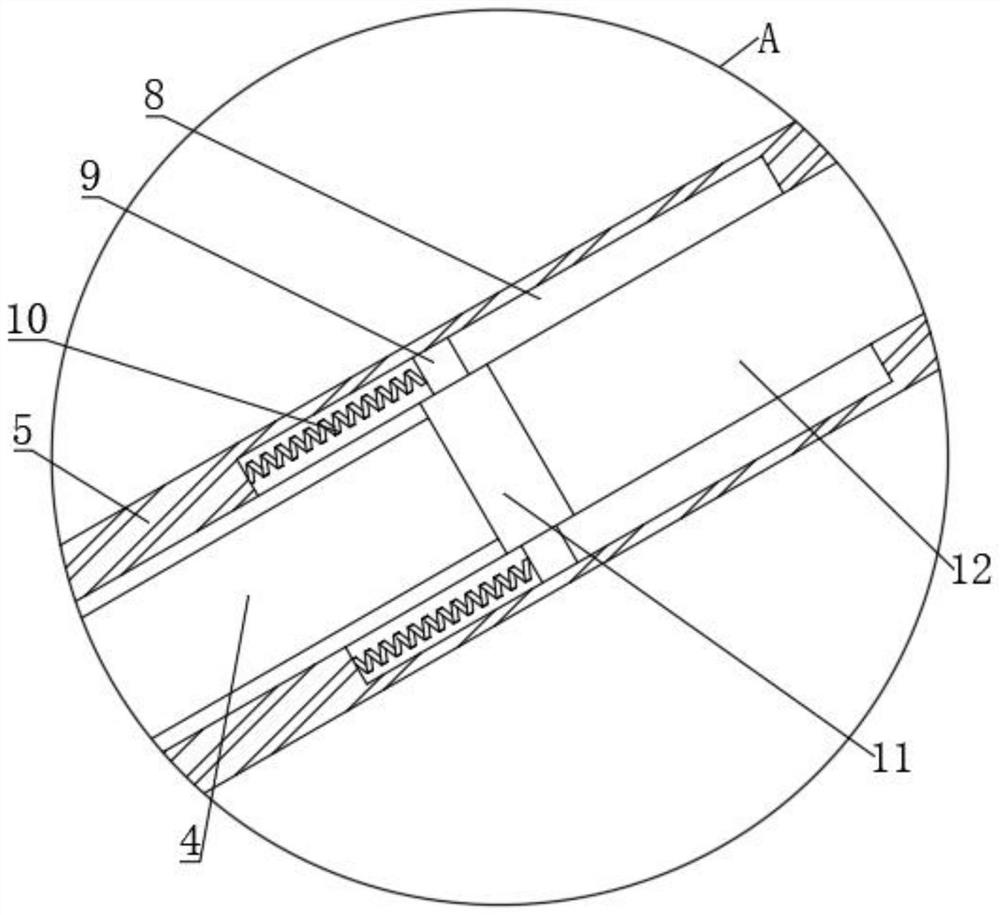

[0055] refer to Figure 1-6 , an anti-seepage geomembrane preparation method, one side of the outer rod 5 is rotatably connected with a plurality of first efficiency plates 15, the cross section of the first efficiency plates 15 is arranged in a crescent shape, the first efficiency plates 15 and the outer rod The same second spring 17 is fixed between 5 by bolts.

[0056] Further, a resistance-increasing portion 16 is provided on the inner arc surface of the first efficiency-enhancing plate 15, and the cross-section of the resistance-increasing portion 16 is arranged in a folded line shape, so that the surface roughness of the first efficiency-enhancing plate 15 can be increased, thereby further increasing the effect of the slurry on the first efficiency increasing plate 15. Resistance of the booster plate 15.

[0057] Further, the side of the outer rod 5 away from the first booster plate 15 is rotatably connected with a plurality of second booster plates 18 through bearings....

Embodiment 3

[0061] refer to Figure 1-3 and Figure 7-8 , an anti-seepage geomembrane preparation method, the air outlet 7 is bonded with a diaphragm 21, the diaphragm 21 is made of elastic material, and the diaphragm 21 is provided with a cut-off opening 22.

[0062] When in use, the compressed air enters the cut-off port 22 from the air storage chamber 12. As the outlet becomes smaller, the elastic diaphragm 21 expands, and the air is discharged from the cut-off port 22, and the cut-off port 22 also becomes larger. When the sheet 21 expands to the limit value, the phenomenon of retraction occurs, the cut-off opening 22 becomes smaller instantly, and the large air bubbles are cut off, so that the large air bubbles can be divided into many small air bubbles, which effectively increases the contact area between the air bubbles and the slurry, and improves the mixing efficiency. At the same time, it is equivalent to pressurizing the air again, which further improves the movement activity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com