High-toughness alumina-based composite ceramic substrate and preparation method thereof

A technology of tough alumina and composite ceramics, which is applied in the field of high-strength and tough alumina-based composite ceramic substrates and its preparation, which can solve the problem of difficult rod-shaped structure reinforcement and toughening, difficult to effectively improve bending strength and fracture toughness, and low formation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present embodiment provides a high-strength and tough alumina-based composite ceramic substrate and a preparation method, and the specific steps are as follows:

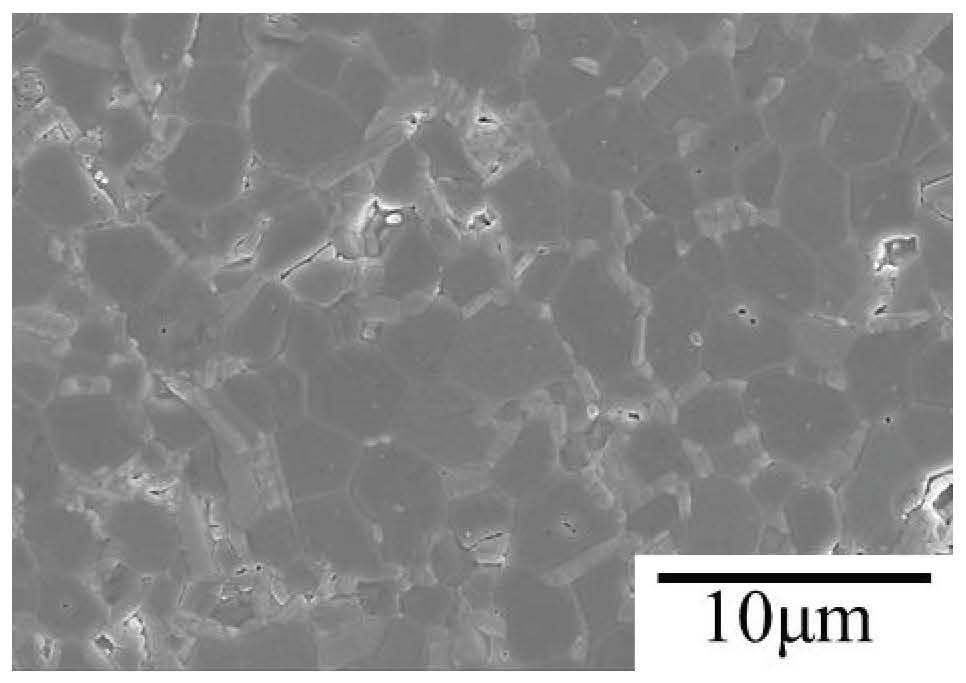

[0040] 1. Weigh 92 parts by mass of Al 2 O 3 Powder, 8 parts by mass of La 2 O 3 The powder is uniformly mixed by ball milling with a planetary ball mill, dried and sieved. The ball milling speed is 350r / min, and the ball milling time is 8h; the obtained powder is poured into a dry pressing mold, and pressed by a dry pressing machine, the pressure is 4MPa, and the pressure is maintained. 2 min to obtain a dry-pressed body; the dry-pressed body is placed in a high-temperature muffle furnace for sintering, the sintering temperature is 1500 °C, and the temperature is kept for 1 h to obtain a ceramic sintered body 1, and a rod-shaped LaAl is formed. 11 O 18 , see the microstructure diagram figure 1 ;

[0041] 2. The ceramic sintered body 1 is crushed with an agate grinding bowl, and then sieved through a...

Embodiment 2

[0046] 1. Weigh 94 parts by mass of Al 2 O 3 Powder, 6 parts by mass of La 2 O 3 The powder is uniformly mixed by ball milling with a planetary ball mill, dried and sieved. The ball milling speed is 350r / min, and the ball milling time is 8h; the obtained powder is poured into a dry pressing mold, and pressed by a dry pressing machine, the pressure is 4MPa, and the pressure is maintained. 2 min to obtain a dry-pressed green body; place the dry-pressed green body in a high-temperature muffle furnace for sintering, the sintering temperature is 1500° C., and the temperature is kept for 1 h to obtain a ceramic sintered body 1;

[0047] 2. The ceramic sintered body 1 is crushed with an agate grinding bowl, and then sieved through a 3000-mesh sieve to obtain the powder 2;

[0048] 3. Weigh 3 parts by mass of powder 2, 93 parts by mass of Al 2 O 3 Powder, 15 parts by mass ZrO 2 The powder is uniformly mixed by ball milling, dried and sieved to obtain powder 3; the ball milling s...

Embodiment 3

[0052] 1. Weigh 93 parts by mass of Al 2 O 3 Powder, 7 parts by mass of La 2 O 3 The powder is uniformly mixed by ball milling with a planetary ball mill, dried and sieved. The ball milling speed is 350r / min, and the ball milling time is 8h; the obtained powder is poured into a dry pressing mold, and pressed by a dry pressing machine, the pressure is 4MPa, and the pressure is maintained. 2 min to obtain a dry-pressed green body; place the dry-pressed green body in a high-temperature muffle furnace for sintering, the sintering temperature is 1500° C., and the temperature is kept for 1 h to obtain a sintered ceramic body 1;

[0053]2. The ceramic sintered body 1 is crushed by an agate grinding bowl, and then sieved through a 3000-mesh sieve to obtain the powder body 2;

[0054] 3. Weigh 6 parts by mass of powder 2, 84 parts by mass of Al 2 O 3 Powder, 10 parts by mass of ZrO 2 The powder is uniformly mixed by ball milling, dried and sieved to obtain powder 3; the ball mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com