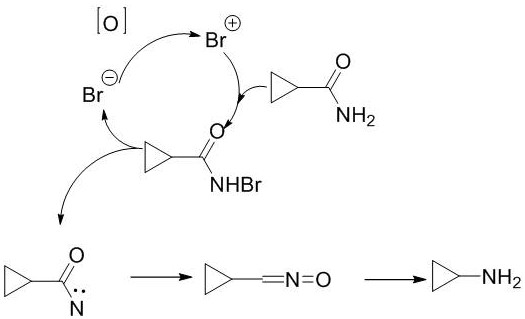

Method for preparing cyclopropylamine through Hofmann rearrangement by using hydrogen peroxide

A technology of hydrogen peroxide and cyclopropylamine, applied in rearrangement reaction preparation, chemical instruments and methods, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Dissolve 300 g (3.5 mol) of cyclopropanamide and 725 g (7.0 mol) of sodium bromide in water, cool down to 0 degrees Celsius, add catalyst orthorhombic titanium-silicon molecular sieve TS-11.2 g, and dropwise add hydrogen peroxide (27% ) 444g (7.0 mol) and 725g (7.0 mol) of sodium hydroxide aqueous solution (32%), incubated for 1 hour, then heated to 70 degrees Celsius, and distilled simultaneously to obtain 110 g (1.9 mol) of cyclopropylamine with a yield of 54%.

[0024] The above mother liquor is filtered, the catalyst is recovered, and the water is removed by concentration, crystallized after cooling, and the sodium carbonate is filtered off to obtain the filtrate as the mother liquor.

Embodiment 2

[0026] Dissolve 300 g (3.5 mol) of cyclopropanamide in the mother liquor, cool it to 0 degrees Celsius, add catalyst orthorhombic titanium-silicon molecular sieve TS-11.2 g, and dropwise add 444 g (3.5 mol) of hydrogen peroxide (27%) and hydrogen into it. Sodium oxide aqueous solution (32%) 725g (7.0 mol) was incubated for 1 hour, then heated to 70 degrees Celsius, and simultaneously distilled to obtain 125 g (2.2 mol) of cyclopropylamine with a yield of 61%.

[0027] The above mother liquor was concentrated to remove water, crystallized after cooling, and the sodium carbonate was filtered off to obtain the filtrate as mother liquor.

Embodiment 3

[0029] Dissolve 300 g (3.5 mol) of cyclopropanamide in the mother liquor, cool it to 0 degrees Celsius, add catalyst orthorhombic titanium-silicon molecular sieve TS-11.2 g, and dropwise add 444 g (3.5 mol) of hydrogen peroxide (27%) and hydrogen into it. Sodium oxide aqueous solution (32%) 725g (7.0 mol) was incubated for 1 hour, then heated to 90 degrees Celsius, and simultaneously distilled to obtain 131 g (2.3 mol) of cyclopropylamine with a yield of 64%.

[0030] The above mother liquor was concentrated to remove water, crystallized after cooling, and the sodium carbonate was filtered off to obtain the filtrate as mother liquor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com