Preparation method of attractant feed additive for suckling pigs

A feed additive and food-inducing technology, which is applied in the field of preparation of suckling pig food-inducing feed additives, can solve problems such as unfavorable human health, susceptibility to diseases, and the development of pig breeding industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

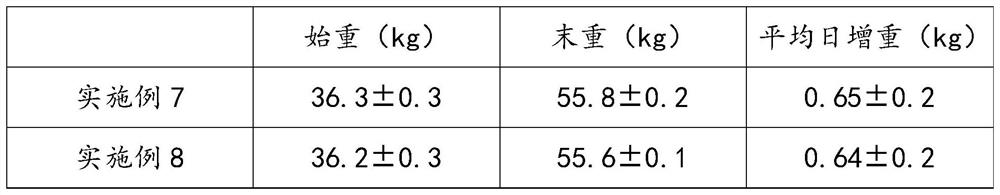

Examples

Embodiment 1

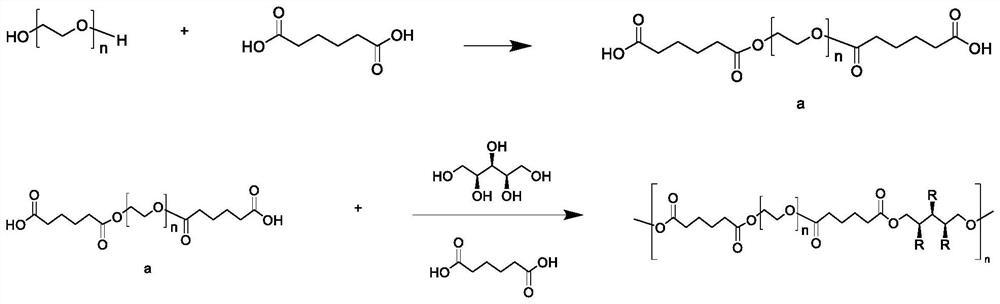

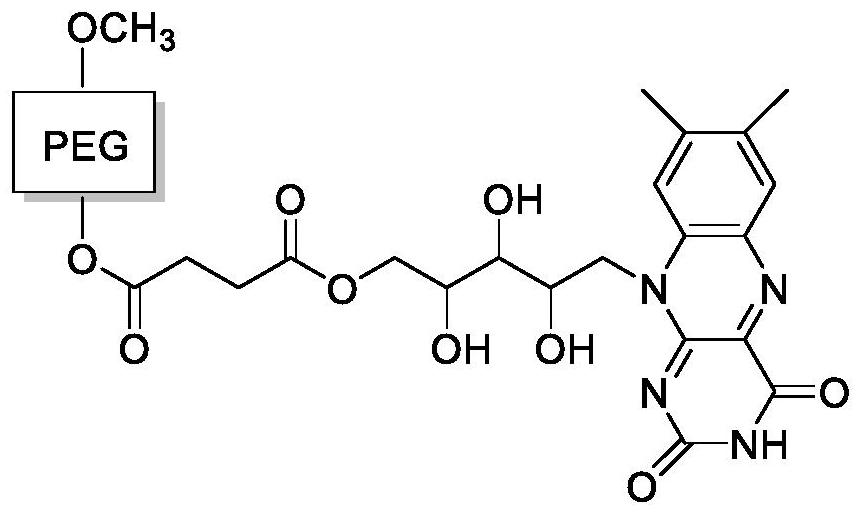

[0031] Described hydrophilic initiator comprises the following steps to make:

[0032] Step S21, adding polyethylene glycol monomethyl ether and succinic anhydride to 1,2-dichloroethane, stirring at a constant speed for 15min at room temperature, then adding 4-dimethylaminopyridine, continuing to stir and react for 15min, after the reaction is completed The temperature was raised to 65°C, and the reaction was kept for 24 hours. After that, the 1,2-dichloroethane was distilled off under reduced pressure, and saturated aqueous sodium carbonate solution was added. The temperature was cooled to room temperature and stirred at a constant speed and reacted for 1 hour. After the reaction was completed, suction filtration and extraction with ethyl acetate three times , stand for liquid separation, adjust the pH of the aqueous layer with 10% dilute hydrochloric acid by mass until pH=2, and then extract three times with dichloromethane, take the organic phase, and distill under reduced p...

Embodiment 2

[0035] Described hydrophilic initiator comprises the following steps to make:

[0036]Step S21, adding polyethylene glycol monomethyl ether and succinic anhydride to 1,2-dichloroethane, stirring at a constant speed for 15min at room temperature, then adding 4-dimethylaminopyridine, continuing to stir and react for 15min, after the reaction is completed The temperature was raised to 65°C, and the reaction was kept for 24 hours. After that, the 1,2-dichloroethane was distilled off under reduced pressure, and saturated aqueous sodium carbonate solution was added. The temperature was cooled to room temperature and stirred at a constant speed and reacted for 1 hour. After the reaction was completed, suction filtration and extraction with ethyl acetate three times , stand for liquid separation, adjust the pH of the aqueous layer with 10% dilute hydrochloric acid by mass until pH=2, and then extract three times with dichloromethane, take the organic phase, and distill under reduced pr...

Embodiment 3

[0039] Described hydrophilic initiator comprises the following steps to make:

[0040] Step S21, adding polyethylene glycol monomethyl ether and succinic anhydride to 1,2-dichloroethane, stirring at a constant speed for 15min at room temperature, then adding 4-dimethylaminopyridine, continuing to stir and react for 15min, after the reaction is completed The temperature was raised to 65°C, and the reaction was kept for 24 hours. After that, the 1,2-dichloroethane was distilled off under reduced pressure, and saturated aqueous sodium carbonate solution was added. The temperature was cooled to room temperature and stirred at a constant speed and reacted for 1 hour. After the reaction was completed, suction filtration and extraction with ethyl acetate three times , stand for liquid separation, adjust the pH of the aqueous layer with 10% dilute hydrochloric acid by mass until pH=2, and then extract three times with dichloromethane, take the organic phase, and distill under reduced p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com