Cobalt-based metal/metal oxide hydrogen evolution catalyst with out-phase junction as well as preparation and application of cobalt-based metal/metal oxide hydrogen evolution catalyst

A technology based on oxides and base metals, applied in the field of hydrogen evolution catalysts with fcc/hcp heterogeneous cobalt-based metals/metal oxides, can solve the problems of high electrode prices and restrictions on large-scale use, and achieve excellent catalytic activity, The method is simple and the effect of hydrogen evolution activity is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

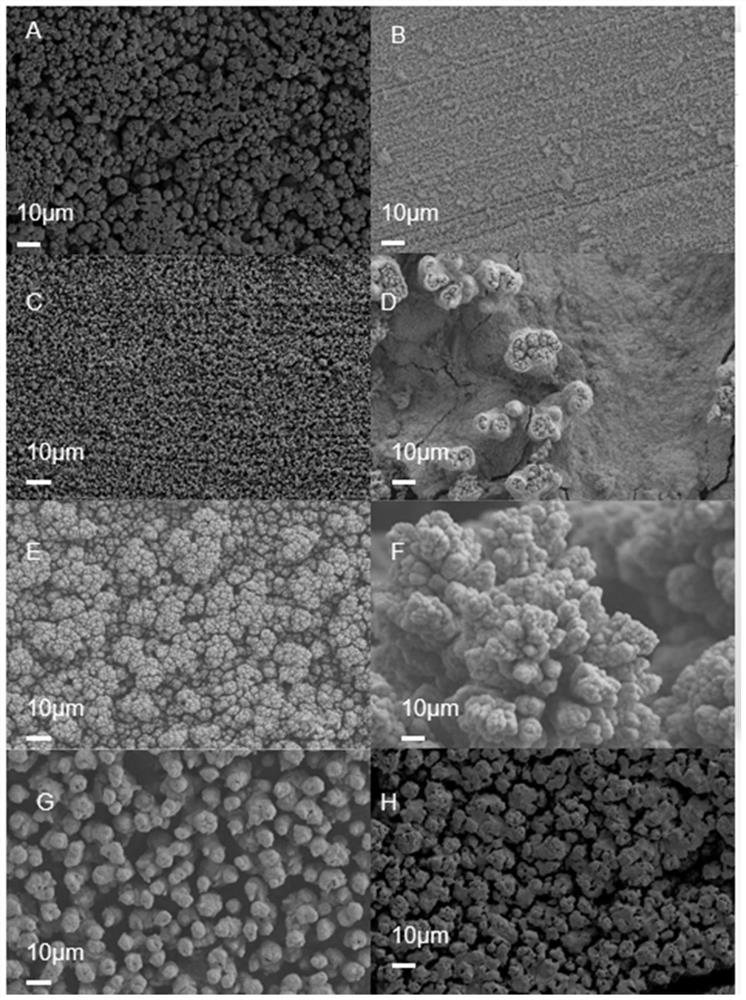

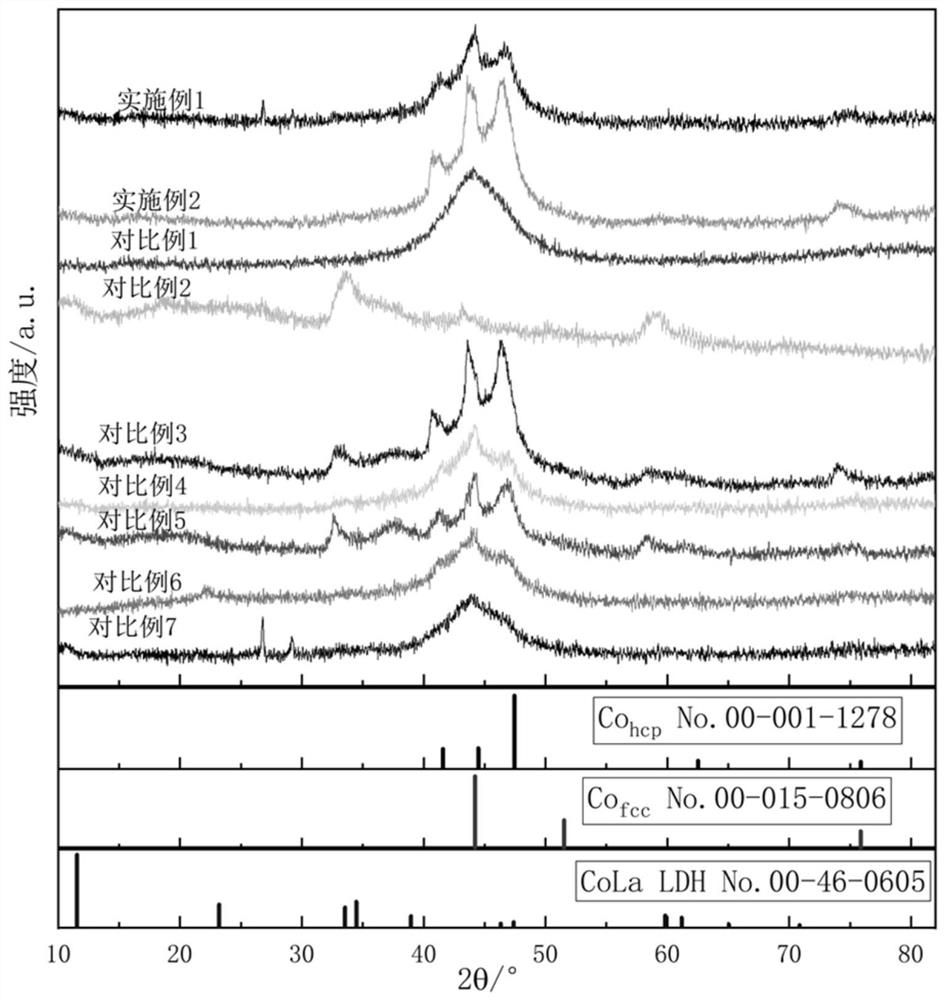

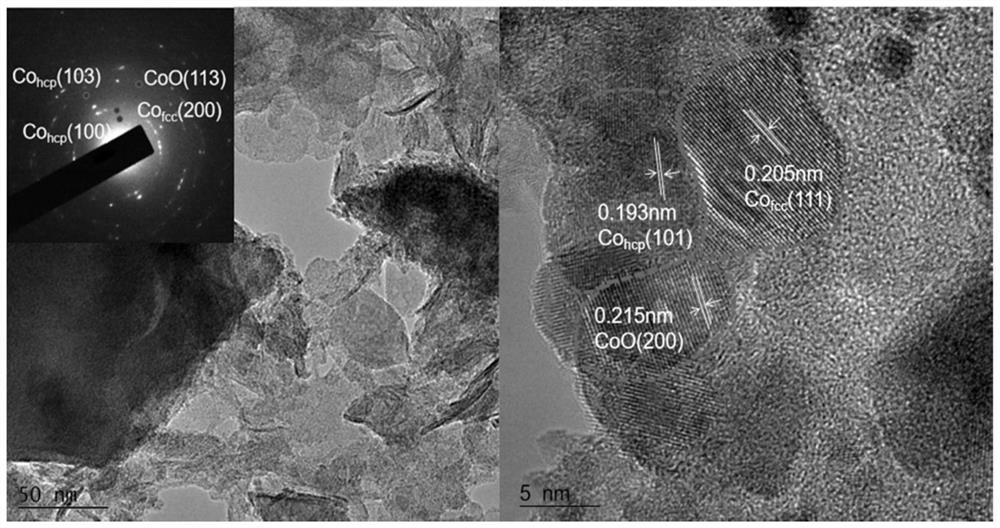

[0036] A preparation method of a heterogeneous junction cobalt-based metal / metal oxide hydrogen evolution catalyst, comprising the following steps:

[0037] (1) Conductive substrate pretreatment: Cut the pure copper sheet into a rectangle of 1x3.5cm size, first ultrasonically clean the cut pure copper sheet in acetone for 20 minutes, then ultrasonically clean it in absolute ethanol for 20 minutes, and after cleaning in acetone and Rinse with plenty of deionized water after cleaning with absolute ethanol.

[0038] (2) Cathode plasma electrodeposition: mix cobalt nitrate, lanthanum nitrate, sodium citrate, NMP with water to obtain a mixed solution, take this mixed solution as an electrolyte, and the concentration of cobalt nitrate in the electrolyte is 0.1mol / L, The concentration of lanthanum nitrate is 0.05mol / L, the concentration of sodium citrate is 0.05mol / L, the concentration of NMP is 8g / L, and the pH of the electrolyte is adjusted to 9 using the sodium hydroxide solution ...

Embodiment 2

[0041] A preparation method of a heterogeneous junction cobalt-based metal / metal oxide hydrogen evolution catalyst, comprising the following steps:

[0042] (1) Conductive substrate pretreatment: Cut the pure copper sheet into a rectangle of 1x3.5cm size, first ultrasonically clean the cut pure copper sheet in acetone for 20 minutes, then ultrasonically clean it in absolute ethanol for 20 minutes, and after cleaning in acetone and Rinse with plenty of deionized water after cleaning with absolute ethanol.

[0043] (2) Cathode plasma electrodeposition: mix cobalt nitrate, lanthanum nitrate, sodium citrate, NMP with water to obtain a mixed solution, take this mixed solution as an electrolyte, and the concentration of cobalt nitrate in the electrolyte is 0.15mol / L, The concentration of lanthanum nitrate is 0.1mol / L, the concentration of sodium citrate is 0.1mol / L, the concentration of NMP is 4g / L, and the pH of the electrolyte is adjusted to 9 by using 1mol / L sodium hydroxide solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com