Vertically oriented graphene as well as preparation method and application thereof

A technology of vertical orientation and graphene, applied in the direction of electrolytic inorganic material coating, etc., can solve the problems of narrow material application range, complex equipment, harsh conditions, etc., and achieve the effects of large-scale production, easy operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

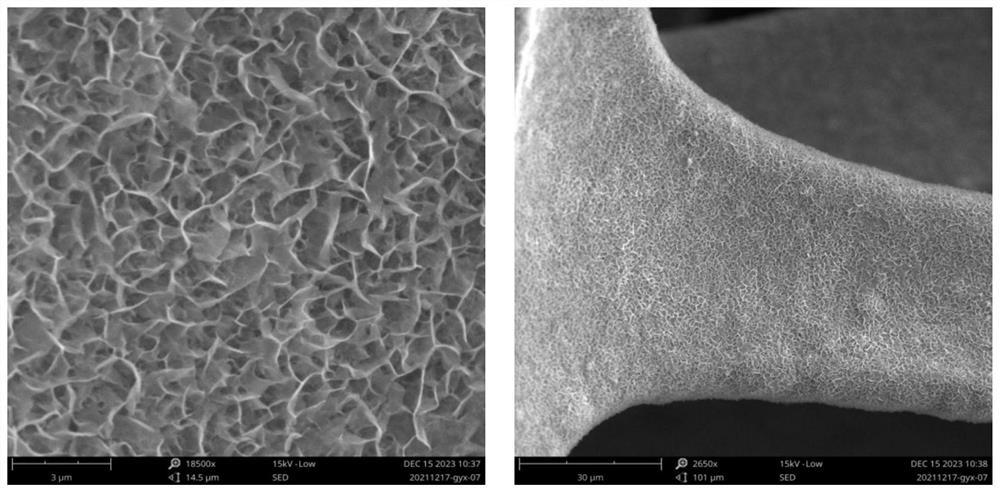

[0027] (1) First, cut the nickel foam into 1cm×2cm slices, wash with hydrochloric acid, deionized water, and ethanol ultrasonically successively, and then put them into an oven for drying. Prepare respectively the graphene oxide dispersion liquid of 0.3g / L and the sodium chloropalladium solution of 4mmol / L, mix with volume ratio 1:1 to form mixed solution, take this mixed solution as electrolyte, take the foamed nickel of above-mentioned oven dry as The working electrode was deposited by cyclic voltammetry for 10 cycles under magnetic stirring. The working electrode was taken out, washed with a large amount of deionized water, and dried to obtain vertically oriented graphene on the foamed nickel sheet.

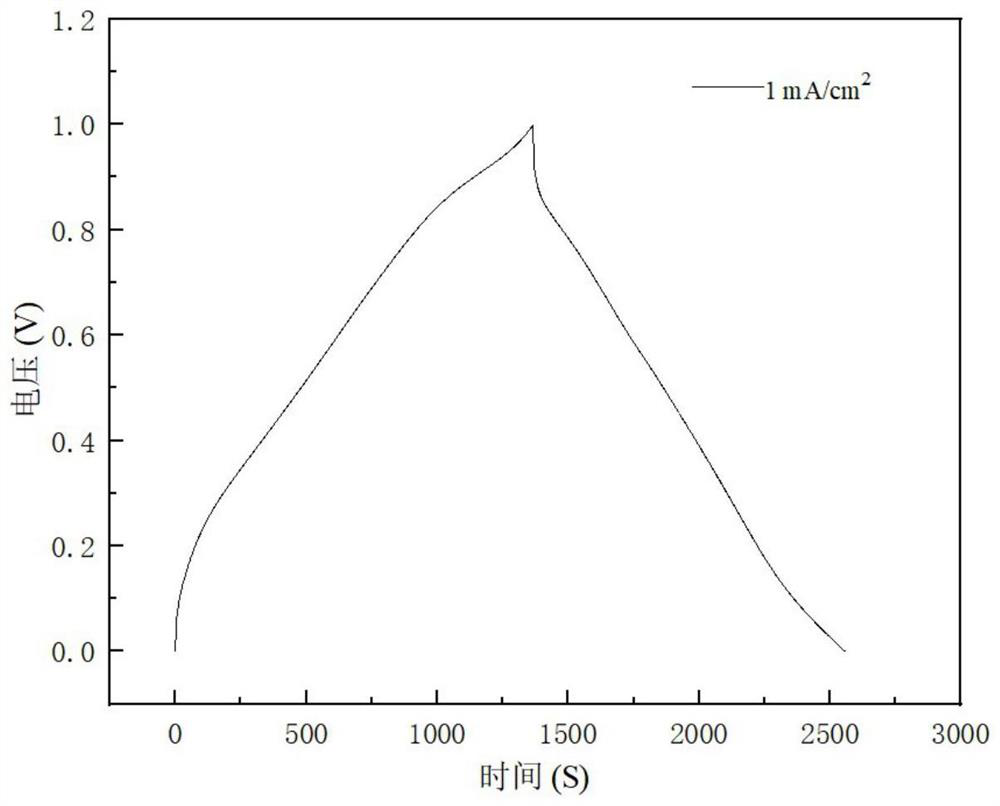

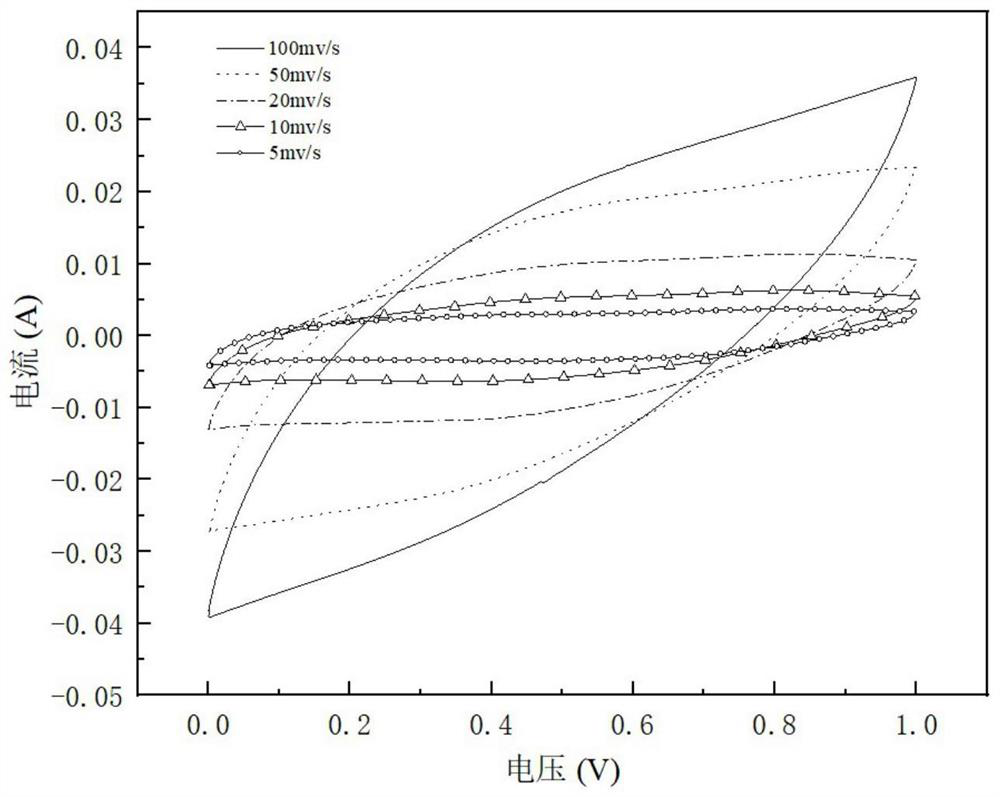

[0028] (2) prepare 0.05mol / L manganese acetate solution and 0.05mol / L sodium sulfate solution respectively, mix with volume ratio 1:1 to form mixed solution, take this mixed solution as electrolyte, with the vertically oriented graphite grown on foam nickel Graphene was used a...

Embodiment 2

[0031] (1) First, cut the nickel foam into 1cm×2cm slices, wash with hydrochloric acid, deionized water, and ethanol ultrasonically successively, and then put them into an oven for drying. Prepare respectively the graphene oxide dispersion liquid of 0.3g / L and the sodium chloropalladium solution of 4mmol / L, mix with volume ratio 1:1 to form mixed solution, take this mixed solution as electrolyte, take the foamed nickel of above-mentioned oven dry as The working electrode was deposited by cyclic voltammetry for 10 cycles under magnetic stirring. The working electrode was taken out, washed with a large amount of deionized water, and dried to obtain vertically oriented graphene on the foamed nickel sheet.

[0032] (2) respectively prepare 0.06mol / L manganese acetate solution and 0.06mol / L sodium sulfate solution, mix with volume ratio 1:1 to form a mixed solution, take this mixed solution as electrolyte, and use the vertically oriented graphite grown on foam nickel Graphene is th...

Embodiment 3

[0034] (1) First, cut the nickel foam into 1cm×2cm slices, wash with hydrochloric acid, deionized water, and ethanol ultrasonically successively, and then put them into an oven for drying. Prepare respectively the graphene oxide dispersion liquid of 0.3g / L and the sodium chloropalladium solution of 4mmol / L, mix with volume ratio 1:1 to form mixed solution, take this mixed solution as electrolyte, take the foamed nickel of above-mentioned oven dry as The working electrode was deposited by cyclic voltammetry for 5 cycles under magnetic stirring. The working electrode was taken out, washed with a large amount of deionized water, and dried to obtain vertically oriented graphene on the nickel foam sheet.

[0035] (2) Prepare 0.06mol / L manganese acetate solution and 0.06mol / L sodium sulfate solution respectively, mix them with a volume ratio of 1:1 to form a mixed solution, use the mixed solution as an electrolyte, and use the vertically oriented graphene grown on the nickel foam Fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area specific capacitance | aaaaa | aaaaa |

| Area specific capacitance | aaaaa | aaaaa |

| Area specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com