Oil-rich coal self-heating and electric heating coupled in-situ pyrolysis system

An in-situ pyrolysis and electric heating technology, applied in wellbore/well components, isolation devices, production fluids, etc., can solve the problems of low utilization rate of thermal energy, long pyrolysis cycle, immature technology, etc., and reduce carbon emissions. , reduce emissions, improve the effect of pyrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail:

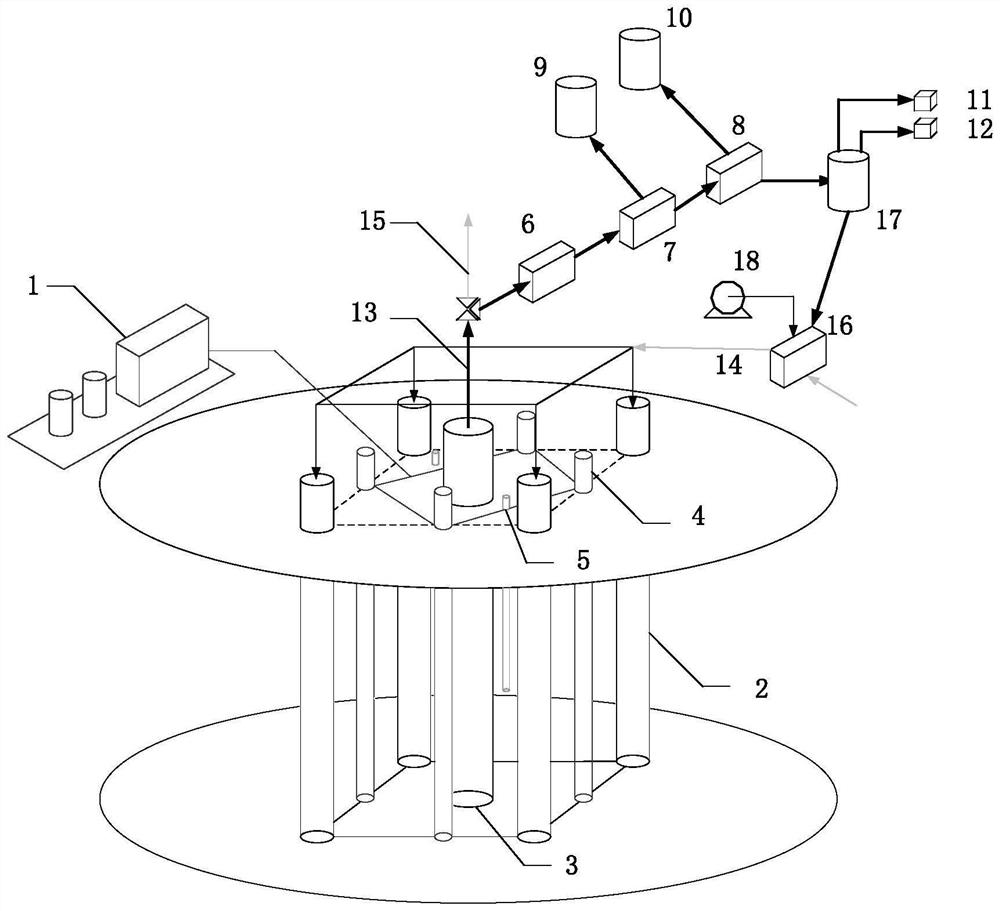

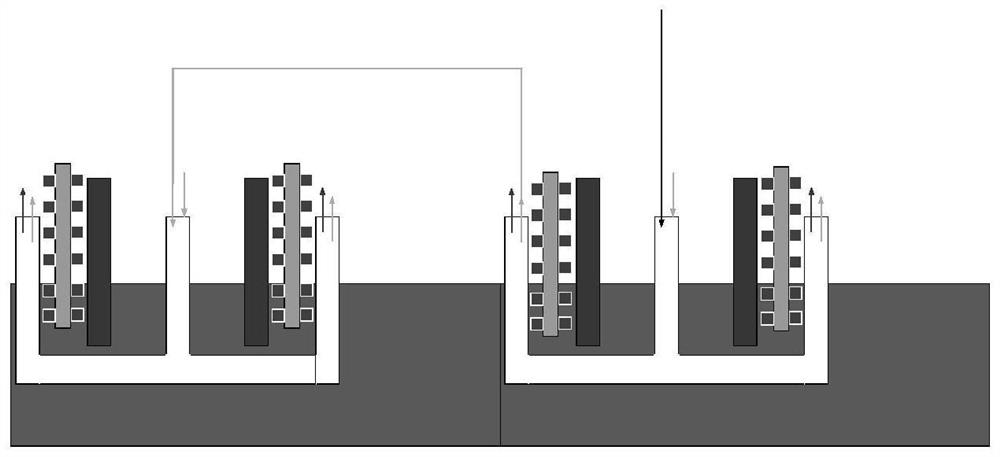

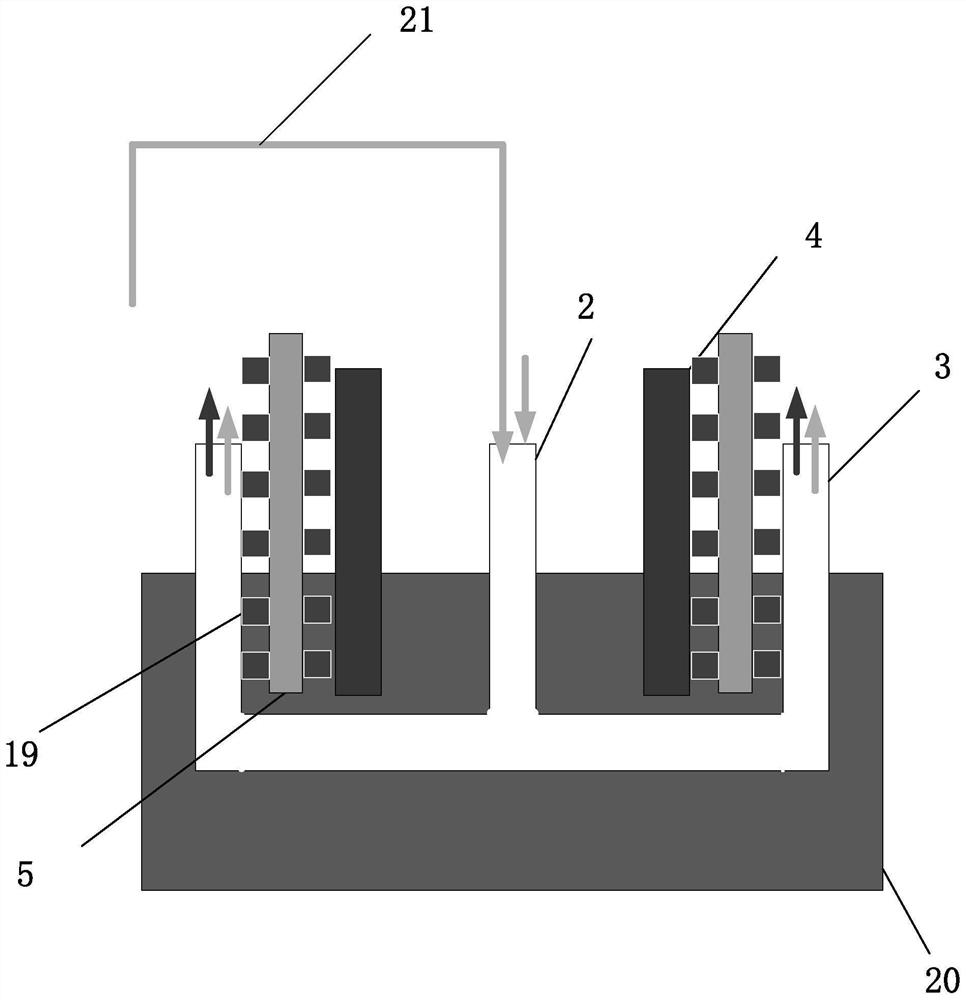

[0030] see figure 1 , the oil-rich coal self-generated heat and electric heating coupled in-situ pyrolysis system provided by the present invention includes a wind-light complementary power generation device 1, a heat injection well / air cooling inlet well 2, a production well / air cooling outlet well 3, and electric heating Well 4, temperature monitoring well 5, high temperature heat exchanger 6, primary separation unit 7, medium temperature coal tar storage tank 9, secondary separation unit 8, low temperature coal tar storage tank 10, combustion chamber 16, gas separation unit 17, and Fan 18. The system comprehensively considers the air supply required by the slow oxidation of oil-rich coal, temperature monitoring and control, efficient well layout, and the process of utilizing waste heat in the block, combined with the pressure swing adsorption method to separate N ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com