Lithium ferric manganese phosphate positive electrode material with iron and manganese elements in full-concentration gradient distribution and preparation method of lithium ferric manganese phosphate positive electrode material

A lithium iron manganese phosphate, full concentration gradient technology, applied in non-metallic elements, chemical instruments and methods, electrical components, etc., can solve the problem of poor discharge capacity and rate performance, affect battery capacity and safety, and reduce battery discharge efficiency. and other problems, to achieve the effects of high tap density, easy maintenance and control, and improved electrochemical lithium intercalation and delithiation capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

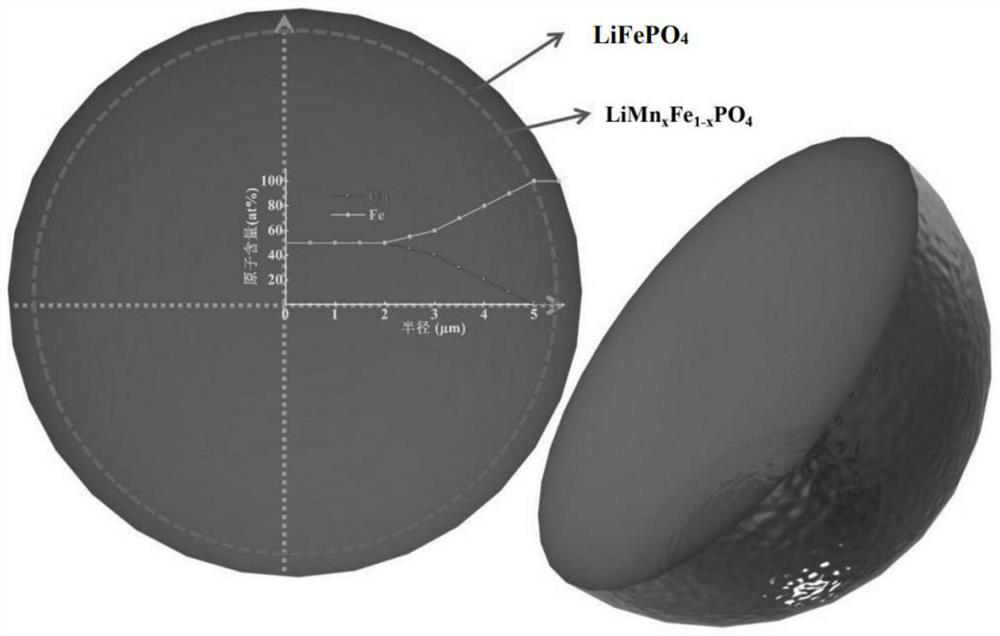

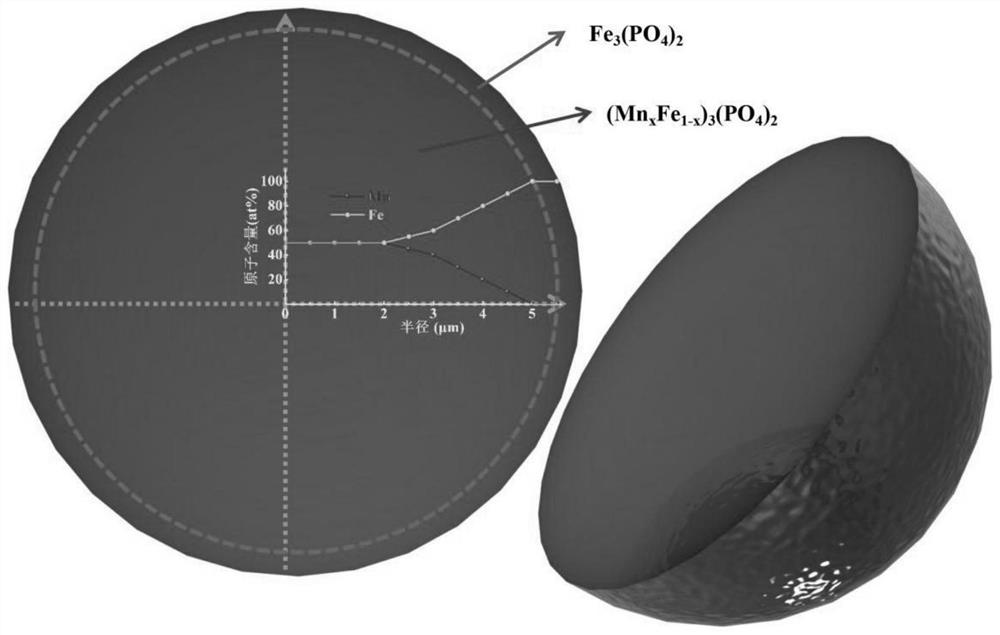

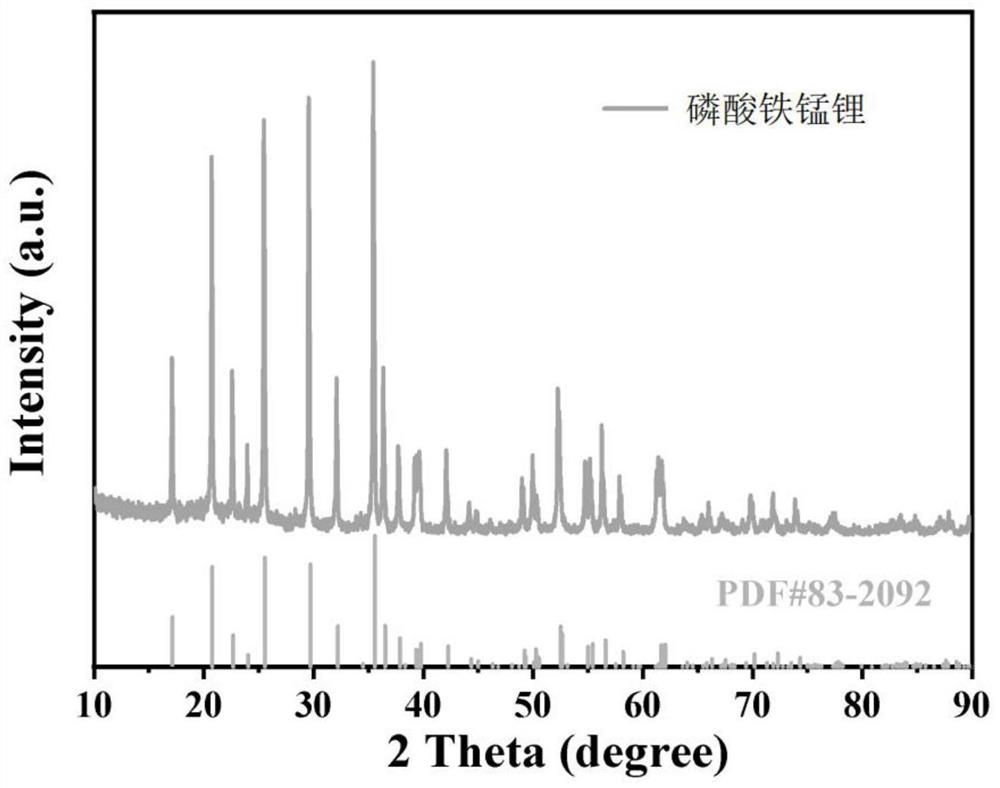

[0044] A lithium iron manganese phosphate cathode material in which iron and manganese elements are distributed in a full concentration gradient, comprising a lithium iron manganese phosphate inner core and a thin lithium iron phosphate coating layer coated on the surface of the lithium iron manganese phosphate inner core, and a lithium iron manganese phosphate cathode material. The molecular formula is LiMn x Fe 1-x PO 4 , where x=0-0.7, and the thin lithium iron phosphate coating layer is LiFePO 4 ; And along the direction from the center of the lithium iron manganese phosphate inner core to the surface layer of the lithium iron manganese phosphate inner core, the content of manganese in the inner core of lithium manganese iron phosphate decreases and the content of iron increases in a gradient. The thickness of the thin lithium iron phosphate coating layer is 2-4 nm, the particle size D50 of the lithium iron manganese phosphate cathode material is 7.8 μm, and the morpholo...

Embodiment 2

[0054] A lithium iron manganese phosphate cathode material in which iron and manganese elements are distributed in a full concentration gradient, comprising a lithium iron manganese phosphate inner core and a thin lithium iron phosphate coating layer coated on the surface of the lithium iron manganese phosphate inner core, and a lithium iron manganese phosphate cathode material. The molecular formula is LiMn x Fe 1-x PO 4 , where x=0-0.7, and the thin lithium iron phosphate coating layer is LiFePO 4 ; And along the direction from the center of the lithium iron manganese phosphate inner core to the surface layer of the lithium iron manganese phosphate inner core, the content of manganese in the inner core of lithium manganese iron phosphate decreases and the content of iron increases in a gradient. The thickness of the thin lithium iron phosphate coating layer is 2-4 nm, the particle size D50 of the lithium iron manganese phosphate cathode material is 7.5 μm, and the morpholo...

Embodiment 3

[0063] A lithium iron manganese phosphate cathode material in which iron and manganese elements are distributed in a full concentration gradient, comprising a lithium iron manganese phosphate inner core and a thin lithium iron phosphate coating layer coated on the surface of the lithium iron manganese phosphate inner core, and a lithium iron manganese phosphate cathode material. The molecular formula is LiMn x Fe 1-x PO 4 , where x=0-0.7, and the thin lithium iron phosphate coating layer is LiFePO 4 ; And along the direction from the center of the lithium iron manganese phosphate inner core to the surface layer of the lithium iron manganese phosphate inner core, the content of manganese in the inner core of lithium manganese iron phosphate decreases and the content of iron increases in a gradient. The thickness of the thin lithium iron phosphate coating layer is 2-4 nm, the particle size D50 of the lithium iron manganese phosphate cathode material is 7.5 μm, and the morpholo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com