Aqueous positive electrode slurry and preparation method thereof

A technology of positive electrode slurry and positive electrode material, applied in the field of electrochemistry, can solve problems such as pollution of positive electrode oily slurry, and achieve the effects of reducing coating drying temperature, energy consumption and production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

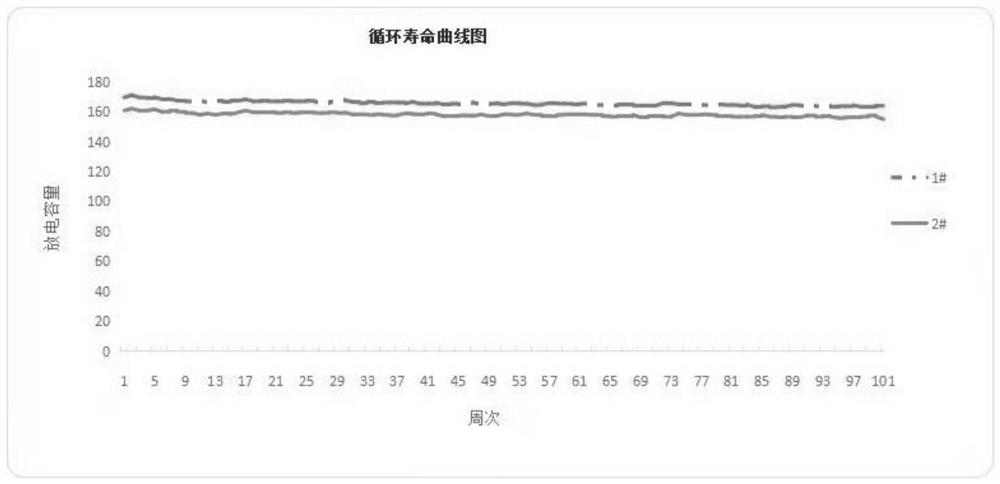

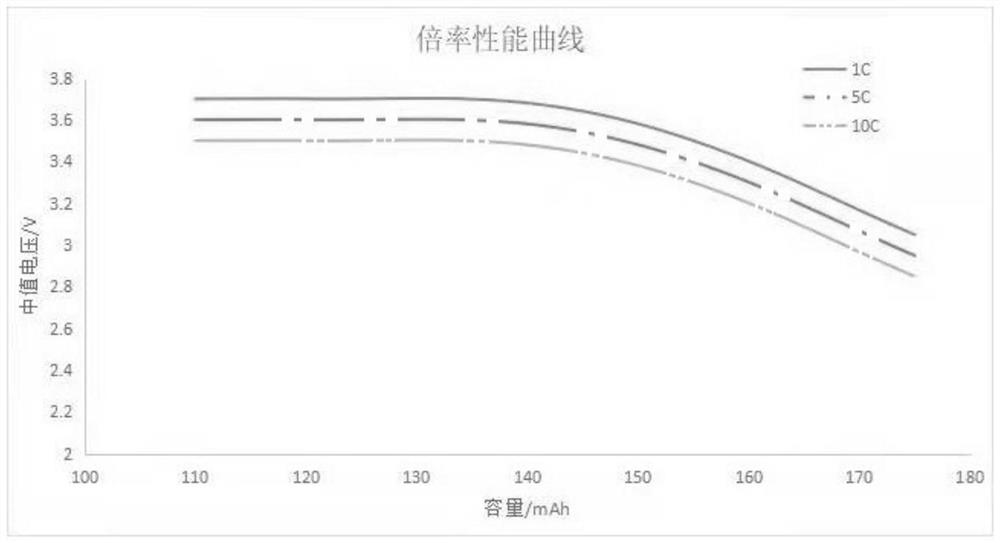

Examples

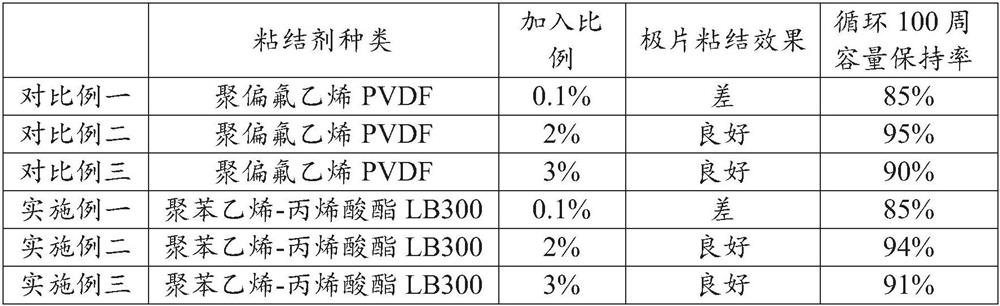

Embodiment 1

[0028] A method for preparing an aqueous positive electrode slurry of this embodiment includes the following steps:

[0029] (1), by mass percentage, mix 0.1% polystyrene-acrylate LB300 water-based adhesive, 1.5% sodium carboxymethyl cellulose CMC and part of deionized water, stir at low speed for 5min first, and the rotating speed is: The revolution is 10r / min, the rotation is 50r / min; then, the high-speed stirring is 30min, the rotation speed is: the revolution is 10r / min, the rotation is 200r / min, and the first glue is formed;

[0030] (2), in the first glue solution, add 1% conductive agent by mass percentage, stir at a high speed for 30min, the rotating speed is: revolution is 10r / min, rotation is 1000r / min, form the second glue solution, this embodiment The conductive agent is conductive graphite;

[0031] (3), in the second glue solution, add 97.1.% of the lithium ion battery positive electrode material using lithium cobalt oxide by mass percentage, stir at a low speed...

Embodiment 2

[0035] A method for preparing an aqueous positive electrode slurry of this embodiment includes the following steps:

[0036] (1), by mass percentage, mix 2% of polystyrene-acrylate LB300 water-based adhesive, 2% of sodium carboxymethyl cellulose CMC and part of deionized water, stir at low speed for 10min first, and the rotating speed is: The revolution is 15r / min, the rotation is 150r / min; then, the high-speed stirring is 50min, and the rotation speed is: the revolution is 25r / min, the rotation is 220r / min, and the first glue is formed;

[0037] (2), in the first glue solution, add 2% conductive agent by mass percentage, stir at a high speed for 50min, the rotating speed is: revolution is 25r / min, rotation is 1200r / min, form the second glue solution, this embodiment The conductive agent is conductive graphite;

[0038] (3), in the second glue solution, add 97.1.% lithium ion battery positive electrode material using lithium cobalt oxide by mass percentage, stir at low speed ...

Embodiment 3

[0042] A method for preparing an aqueous positive electrode slurry of this embodiment includes the following steps:

[0043](1), by mass percentage, mix 3% polystyrene-acrylate LB300 water-based adhesive, 2.5% sodium carboxymethyl cellulose CMC and part of deionized water, stir at low speed for 10min first, and the rotating speed is: The revolution is 25r / min, the rotation is 200r / min; then, the high-speed stirring is 50min, and the rotation speed is: the revolution is 30r / min, the rotation is 250r / min, and the first glue is formed;

[0044] (2), in the first glue solution, add 2.0% conductive agent by mass percentage, stir at a high speed for 50min, the rotating speed is: revolution is 30r / min, rotation is 1500r / min, form the second glue solution, this embodiment The conductive agent is conductive graphite;

[0045] (3), in the second glue solution, add 97.1.% lithium ion battery positive electrode material using lithium cobalt oxide by mass percentage, stir at low speed for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com