High-strength solid electrolyte membrane and preparation method and application thereof

A technology of solid electrolyte membrane and electrolyte membrane, which is applied in the direction of circuits, electrical components, secondary batteries, etc., can solve the problems of low strength of the electrolyte diaphragm, and achieve the effects of reducing the risk of internal short circuit, improving strength, and not being easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

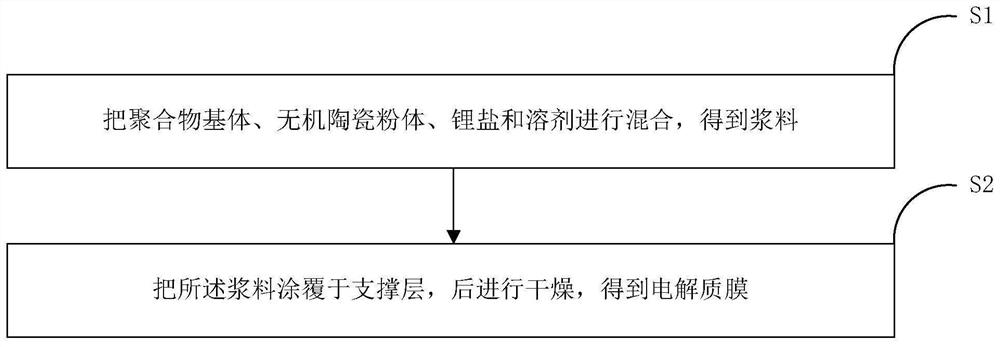

[0052] According to another typical embodiment of the present invention, there is provided a method for preparing a high-strength solid-state electrolyte membrane as described above, the method comprising:

[0053]S1. Mix the polymer matrix, the inorganic ceramic powder, the lithium salt and the solvent to obtain a slurry;

[0054] In some embodiments, the polymer matrix, the inorganic ceramic powder, the lithium salt and the solvent are mixed to obtain a slurry, which specifically includes:

[0055] S1.1. Mix the polymer matrix and the solvent to obtain a solution;

[0056] S1.2. Mix the lithium salt and the solution to obtain an intermediate slurry;

[0057] S1.3. Mix the inorganic ceramic powder and the intermediate slurry to obtain a slurry.

[0058] In some embodiments, the interval time of the interval ultrasonic treatment is 50min-70min, the ultrasonic interval time includes but not limited to 50min, 55min, 60min, 65min, 70min, and the single treatment time of the int...

Embodiment 1

[0080] A preparation method of a solid electrolyte membrane, the method comprising:

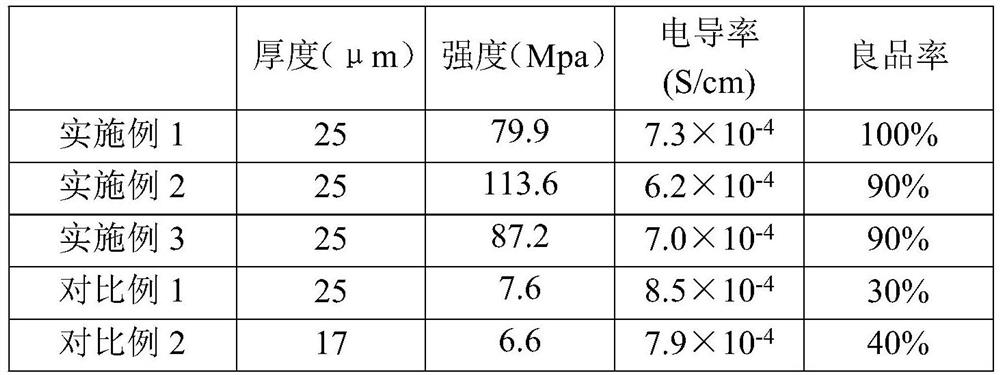

[0081] Weigh 0.57g of PCL into 10ml of dimethyl carbonate solvent, heat and stir, add 0.144g of LiPF6 lithium salt after it is completely dissolved, continue to heat and stir for 1-2 hours, then add Al2O3 powder, add inorganic ceramic powder and stir for 8h, And every hour ultrasound 30min. The uniformly dispersed slurry is evenly scraped onto the PET film to prepare 2 identical coated PET films. After coating, a non-woven film is immediately placed on one PET film, and another PET film is covered to form The symmetrical structure of PET film-composite solid electrolyte-non-woven fabric-composite solid electrolyte film-PET film, and then put it in a drying oven, dried at 30°C for 12 hours, after drying, tear off the PET film, put it in a vacuum drying oven, After drying at 30 °C for 12 h, a composite solid electrolyte membrane was obtained.

Embodiment 2

[0083] A preparation method of a solid electrolyte membrane, the method comprising:

[0084] Weigh 0.57g of PCL into 10ml of dimethyl carbonate solvent, heat and stir, add 0.144g of LiPF6 lithium salt after it is completely dissolved, continue to heat and stir for 1-2 hours, then add Al2O3 powder, add inorganic ceramic powder and stir for 8h, And every hour ultrasound 30min. Scratch the evenly dispersed slurry onto the PET film to prepare 2 copies of the same coated PET film. After coating, immediately place a PE separator (porosity 40%) on one PET film and cover with another PET film to form a symmetrical structure of PET film-composite solid electrolyte-PE-composite solid electrolyte film-PET film, then put it in a drying oven, dry at 30°C for 12h, after drying, tear off the PET film and put it in a vacuum drying oven and drying at 30 °C for 12 h to obtain a composite solid electrolyte membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com