Layered multi-loss mechanism wave-absorbing material and preparation method thereof

A wave-absorbing material and mechanism technology, applied in the field of wave-absorbing materials, to achieve the effect of facilitating impedance matching and enhancing dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045]Second, the present invention provides a method for preparing a layered multi-loss mechanism wave absorbing material, comprising the following steps:

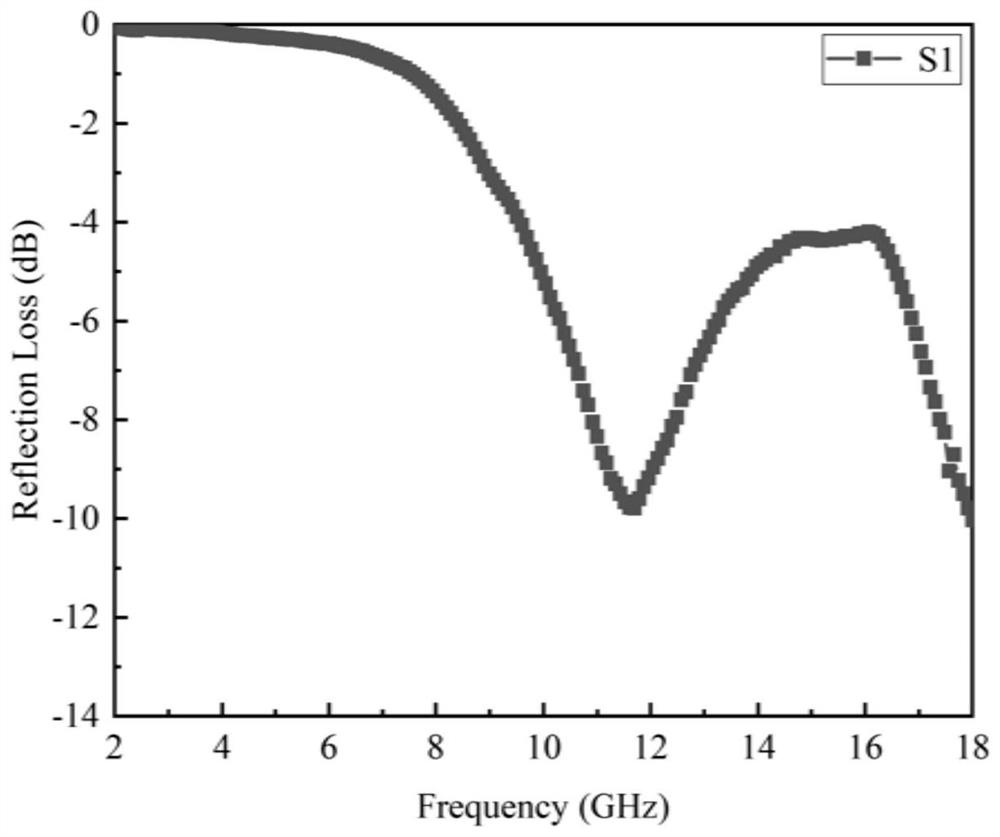

[0046] Preparation of S1 matching layer

[0047] Ni@MXene was added into WPU, stirred and sonicated to obtain the first mixed solution, and the matching layer was obtained by pouring method;

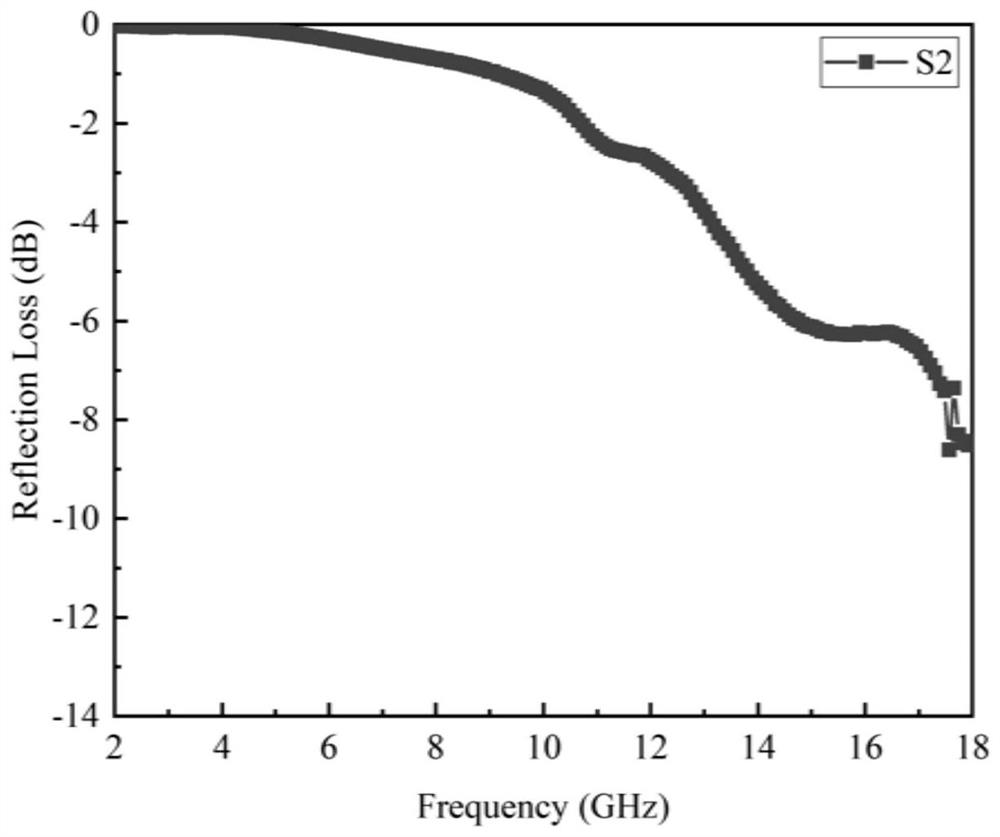

[0048] Preparation of S2 Sandwich Layer

[0049] ZnO@MXene was added into WPU and stirred and sonicated to obtain a second mixed solution, which was poured on the surface of the matching layer to obtain a sandwich layer;

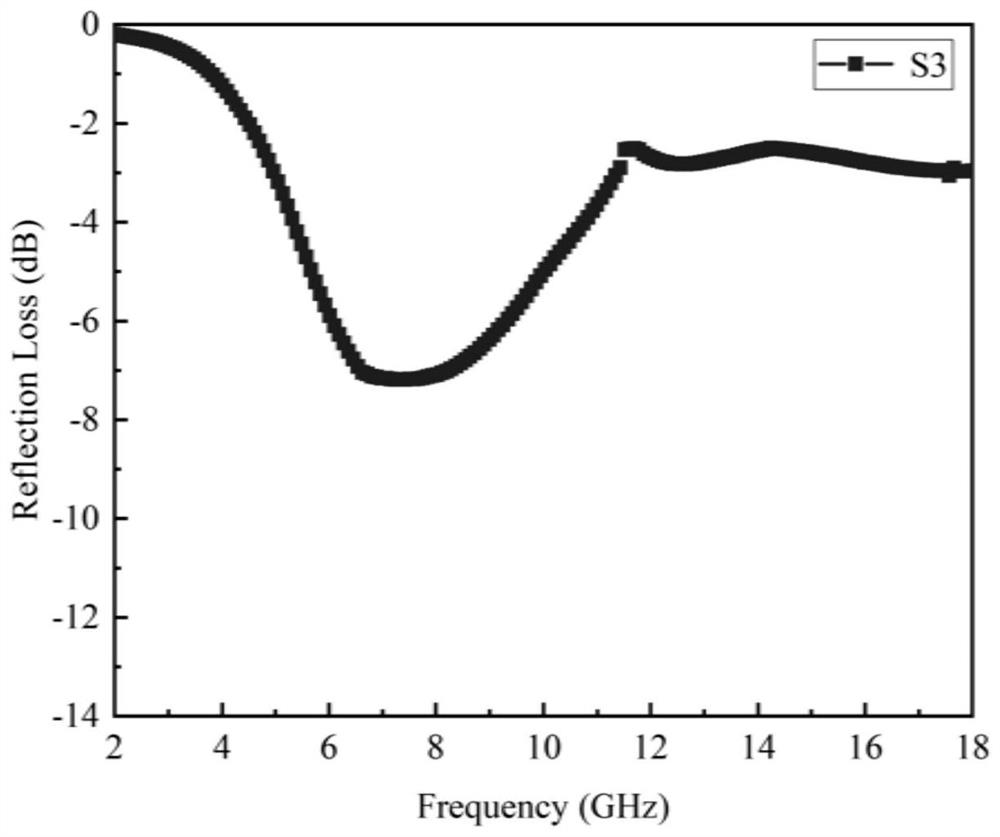

[0050] Preparation of S3 Reflective Layer

[0051] MXene is added into WPU and stirred and sonicated to obtain a third mixed solution, which is poured on the surface of the sandwich layer to obtain a reflective layer.

[0052]

Embodiment 1

[0054] A preparation method of a layered multi-loss mechanism wave absorbing material, comprising the following steps:

[0055] Step 1: Preparation of MXene

[0056] Put 40mL 9M HCl into a 100mL polytetrafluoro beaker, then slowly pour 2g LiF into the beaker and stir for 20min, then take 2g Ti 3 AlC 2 - MAX was slowly poured into a beaker, stirred at 40°C for 24h, and after 24h, the reaction product was centrifuged and washed with water to pH > 5, and then MXene was obtained by ultrasonication and freeze-drying;

[0057] Step 2: Preparation of Ni@MXene composite powder

[0058] with NiCl 2 ·6H 2 The Ni@MXene composite powder was prepared with a mass ratio of O to MXene of 3:1: trisodium citrate (0.4 g) and sodium acetate (3.2 g) were dissolved in 60 mL of ethylene glycol; then 0.6 g of ethylene glycol was added to the solution NiCl 2 ·6H 2 O; after it dissolves, add 0.2g MXene to the solution, stir for 20min and then let stand for 1h; then add 6mL N to the solution 2 H...

Embodiment 2

[0067] The difference between this example and Example 1 is that the mass ratio of Ni to MXene in Ni@MXene is 1:1; the mass ratio of ZnO to MXene in ZnO@MXene is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com