Method for preparing centimeter-level multiphase molybdenum disulfide film

A molybdenum disulfide, centimeter-level technology is applied in the field of preparing centimeter-level multiphase molybdenum disulfide thin films, which can solve problems such as complex process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The heavily doped p-type silica / silicon substrate was ultrasonically treated with acetone, anhydrous ethanol and deionized water in sequence, and then the surface of the silica / silicon substrate was hydrophilic treated with Plasma.

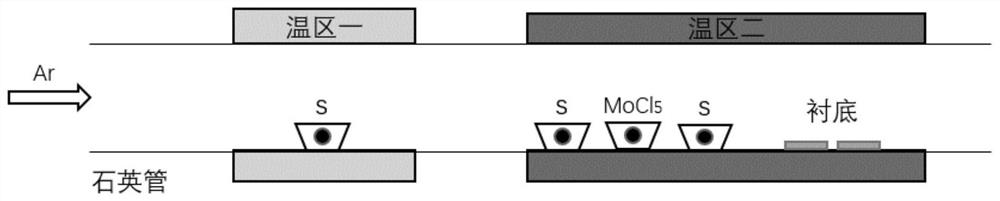

[0039] Three 100mg S element, 20mg MoCl 5respectively placed on the quartz boat, MoCl 5 The ratio of S element and S element is 150:1, and three parts of S element and one part of MoCl are weighed. 5 The powder is placed in a quartz boat and sent to the two temperature zones of the tube furnace. One part of the S element is placed in the first temperature zone, and the remaining two parts of the S element and MoCl are placed 5 The powder is placed in the second temperature zone, MoCl 5 The powder is located between the two parts of S and will be heavily doped with p-type SiO 2 / Si substrate is placed in the second temperature zone MoCl 5 5cm behind the powder, such as figure 1 shown.

[0040] The device was evacuated to 0.1 Pa, 100 sc...

example 1

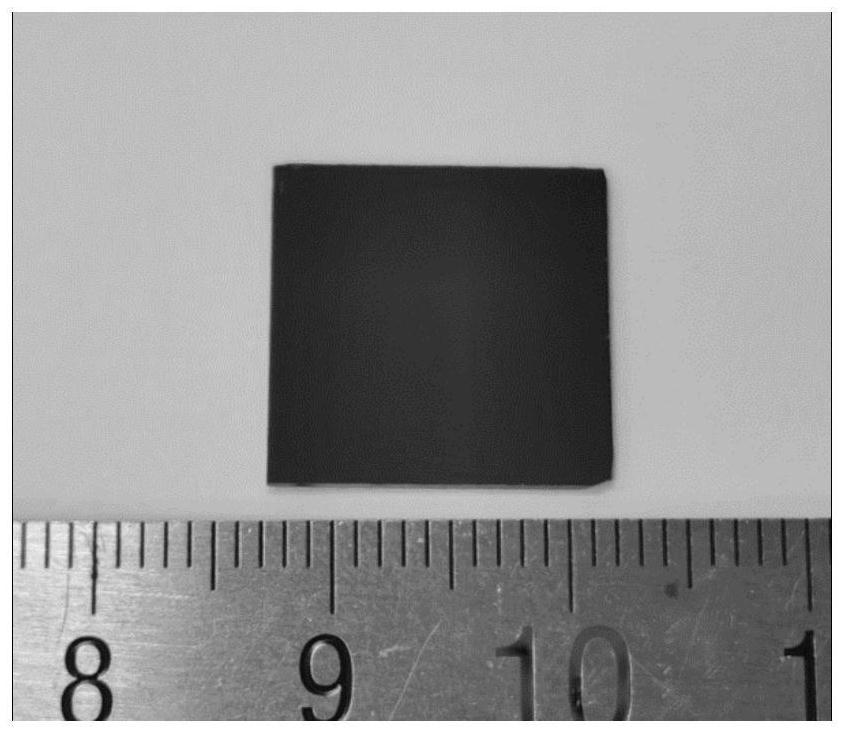

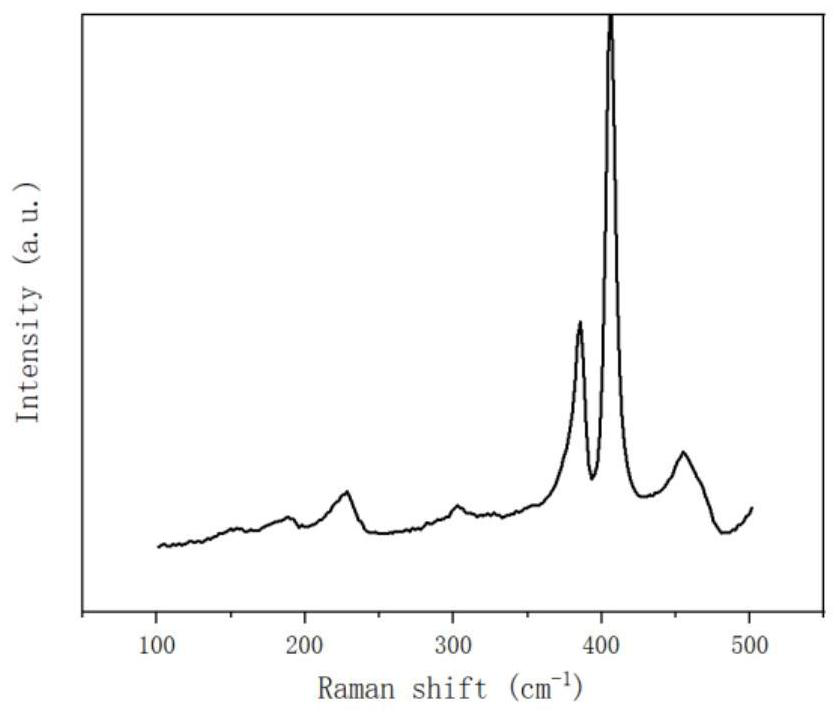

[0042] The optical image of the centimeter-scale heterogeneous molybdenum disulfide thin film grown in Example 1 is as follows figure 2 shown; image 3 For the heterogeneous molybdenum disulfide 100 ~ 500cm -1 Raman spectrum in the range of 350 to 430 cm -1 The typical A of 2H-phase molybdenum disulfide can be observed in the interval 1g and E 2g 1 Raman vibration characteristic peaks ( Figure 4 ), A 1g and E 2g 1 The difference is 20.3cm -1 , showing that the molybdenum disulfide film is a single-layer structure; -1 The typical J of 1T phase molybdenum disulfide can be observed in the interval 1 and J 2 Raman vibration characteristic peaks ( Figure 5 ), proving that this molybdenum disulfide is a monolayer multiphase structure (2H and 1T phases); Image 6 For the comparison of photoluminescence spectra of heterogeneous molybdenum disulfide and pure 2H-phase molybdenum disulfide, the figure shows that the heterogeneous molybdenum disulfide exhibits unique photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com