Anti-interference cable and preparation method thereof

A cable and insulating layer technology, applied in the field of anti-interference cable and its preparation, can solve the problems of short signal transmission distance, distortion, weak anti-signal interference ability, etc., and achieve the effects of superior performance, low cost and novel process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Anti-interference cable

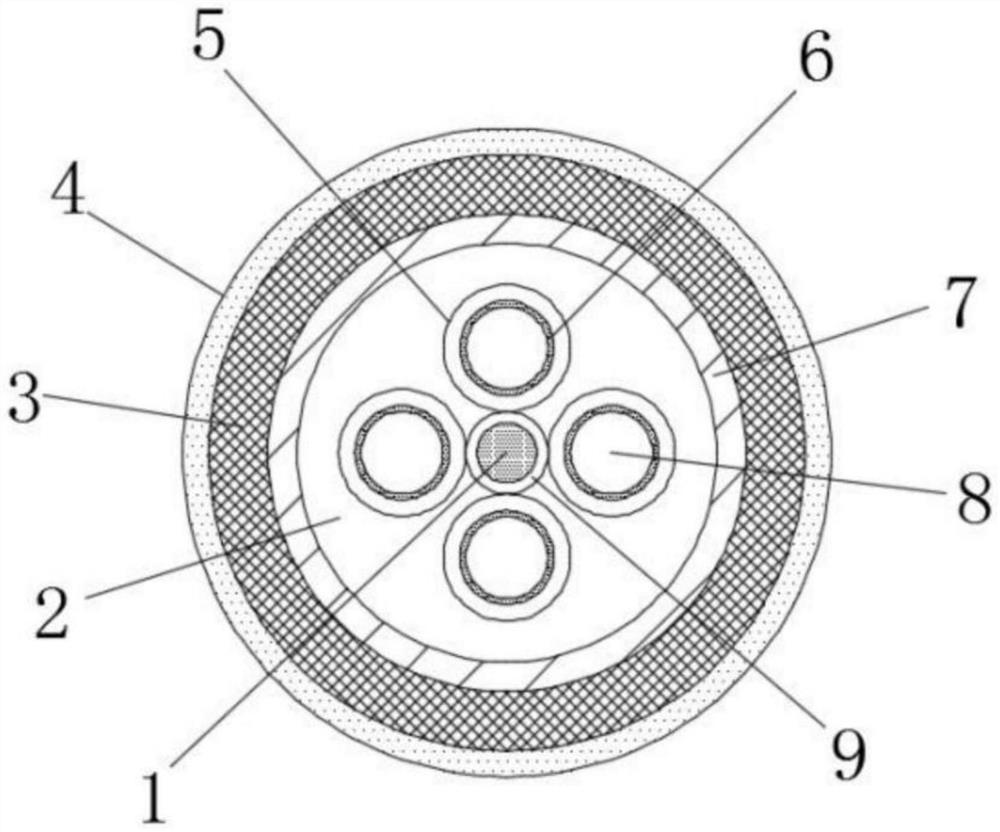

[0039] like figure 1 As shown, an anti-interference cable includes an insulating layer 2, characterized in that an inner core 1 is arranged at the center of the insulating layer 2, and a middle core protective layer 9 is arranged outside the inner core 1, and the middle core The protective layer 9 is bonded in the insulating layer 2, and a plurality of conductors 8 are arranged in the circumference of the inner core 1 at equal intervals. The outer side of each conductor 8 is bonded with an inner shielding layer 6 through epoxy resin. The outer side walls of the inner shielding layer 6 are all bonded with an inner protective layer 5 through epoxy resin, and the inner protective layer 5 is bonded to the insulating layer 2, and an outer shielding layer is provided on the outer side wall of the insulating layer 2. Layer 7.

[0040] An outer protective layer 3 is provided on the outer side wall of the above-mentioned outer shielding laye...

Embodiment 2

[0042] Embodiment 2 The preparation method of anti-jamming cable

[0043] like figure 1 As shown, the preparation method of the above-mentioned anti-interference cable includes the following steps:

[0044] Step 1: Electrolytic copper smelting, continuous casting and rolling to produce Φ8.0mm electrolytic copper rods;

[0045] Step 2: Drawing, annealing and tinning the Φ electrolytic copper rod to make Φ2.5mm soft copper wire;

[0046] Step 3: Twist 19 tinned soft copper wires of Φ2.52mm into bundles, and twist them into 95-140mm with an outer diameter of 12.7mm 2 the conductor;

[0047] Step 4: The insulating layer 2 and the inner shielding layer 6 constitute the insulating shielding layer, and an extrusion die is used;

[0048] Step 5: Wrap the inner shielding layer 6 with an outer diameter of 21.8mm and an oxygen-free soft copper tape with a thickness of 0.1mm and a width of 19mm in the insulating shielding layer;

[0049] Step 6: Wrap a barrier layer with a thickness ...

Embodiment 3

[0054] Embodiment 3 The preparation method of anti-jamming cable

[0055] like figure 1 As shown, the preparation method of the above-mentioned anti-interference cable includes the following steps:

[0056] Step 1: Electrolytic copper smelting, continuous casting and rolling to produce Φ4mm electrolytic copper rods;

[0057]Step 2: Drawing, annealing and tinning the Φ electrolytic copper rod to make Φ3.25mm soft copper wire;

[0058] Step 3: Twist 19 tinned soft copper wires of Φ2.52mm into bundles, and twist them into 140mm with an outer diameter of 12.7mm 2 the conductor;

[0059] Step 4: The insulating layer 2 and the inner shielding layer 6 constitute the insulating shielding layer, and an extrusion die is used;

[0060] Step 5: Wrap the inner shielding layer 6 with an outer diameter of 21.8 mm and an oxygen-free soft copper tape with a thickness of 0.5 mm and a width of 32 mm in the insulating shielding layer;

[0061] Step 6: Wrap a barrier layer with a thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com