Microneedle and manufacturing process thereof

A manufacturing process and microneedle technology, which can be applied to other medical devices, drug devices and other directions, can solve the problems of difficulty in large-scale popularization, time-consuming, high preparation cost, and achieve long-term stable transdermal administration and simple preparation process. , mature and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

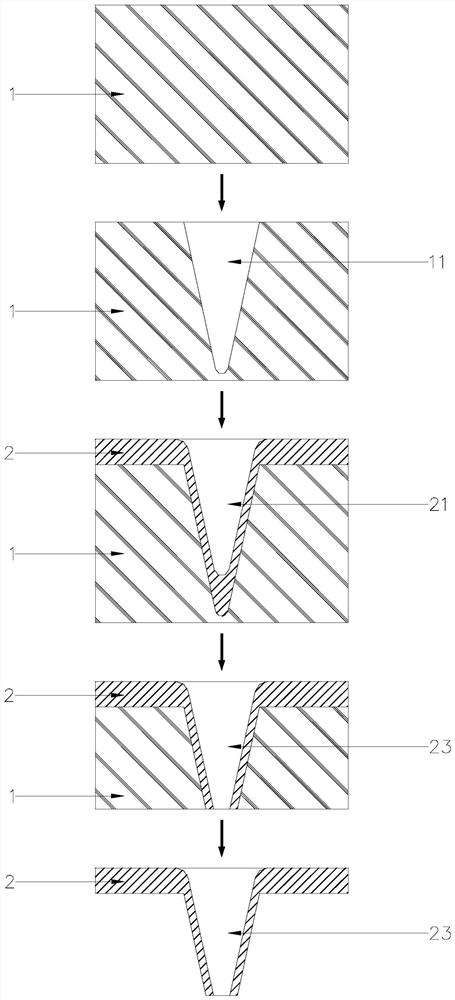

[0035] see figure 1 , a manufacturing process of a microneedle of the present invention comprises the following steps:

[0036] a) Opening: Select a substrate 1 with an appropriate thickness as required, and then etch several concave portions 11 on the top surface of the substrate 1 that do not penetrate the bottom surface. The substrate 1 is a glass substrate, and each of the concave portions 11 are all inverted cones, and each of the inner recesses 11 is etched by maskless etching technology;

[0037] Among them, the maskless etching technology can be a laser etching technology, which can irradiate the top surface of the substrate 1 with a high-energy-density laser, so that the surface material of the irradiated area is subjected to heat, melting, vaporization, plasma formation, volatilization and sputtering. A series of complex physical and even chemical processes such as radiation, etc., finally form the inner recess 11;

[0038] b) Film formation: the needle body membra...

Embodiment 2

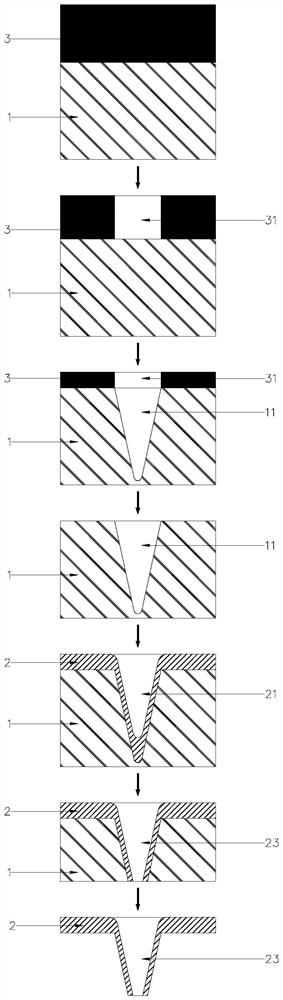

[0044] see figure 2 , a manufacturing process of a microneedle of the present invention comprises the following steps:

[0045] a) Opening: Select a substrate 1 with an appropriate thickness as required, and then etch several concave portions 11 on the top surface of the substrate 1 that do not penetrate the bottom surface. The substrate 1 is a glass substrate, and each of the concave portions 11 are all inverted cones, and each of the inner recesses 11 is etched by photoresist etching technology;

[0046] Among them, the photoresist etching technique is specifically as follows: first, a photoresist is coated on the top surface of the substrate 1 to form a photoresist layer 3 , and after drying, a mask is used to block the photoresist layer 3 , so that the light irradiates the photoresist layer 3 . In some areas, the exposed or unexposed areas of the photoresist layer 3 are dissolved by the developer to form the through holes 31 , and finally the plasma generated under the a...

Embodiment 3

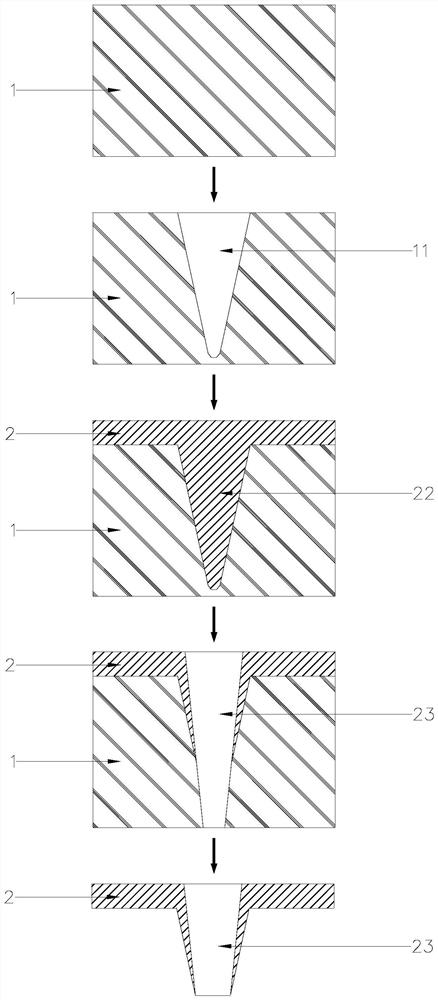

[0053] see image 3 , a manufacturing process of a microneedle of the present invention comprises the following steps:

[0054]a) Opening: Select a substrate 1 with an appropriate thickness according to the needs, and then etch several recesses 11 on the top surface of the substrate 1 that do not penetrate the bottom surface. The substrate 1 is a glass substrate, and each of the recesses 11 are all inverted cones, and each of the inner recesses 11 is etched by maskless etching technology;

[0055] Among them, the maskless etching technology can be a laser etching technology, which can irradiate the top surface of the substrate 1 with a high-energy-density laser, so that the surface material of the irradiated area is subjected to heat, melting, vaporization, plasma formation, volatilization and sputtering. A series of complex physical and even chemical processes such as radiation, etc., finally form the inner recess 11;

[0056] b) Film formation: the needle body film layer 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com