Ridge-free fused mass structure manganese trifluoride material and preparation method thereof

A manganese trifluoride and anhydrous hydrogen fluoride technology, applied in manganese halide and other directions, can solve the problems of low working temperature, high equipment requirements, short fluorination time, etc., and achieve good high temperature stability, good chemical stability, and fluorination. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

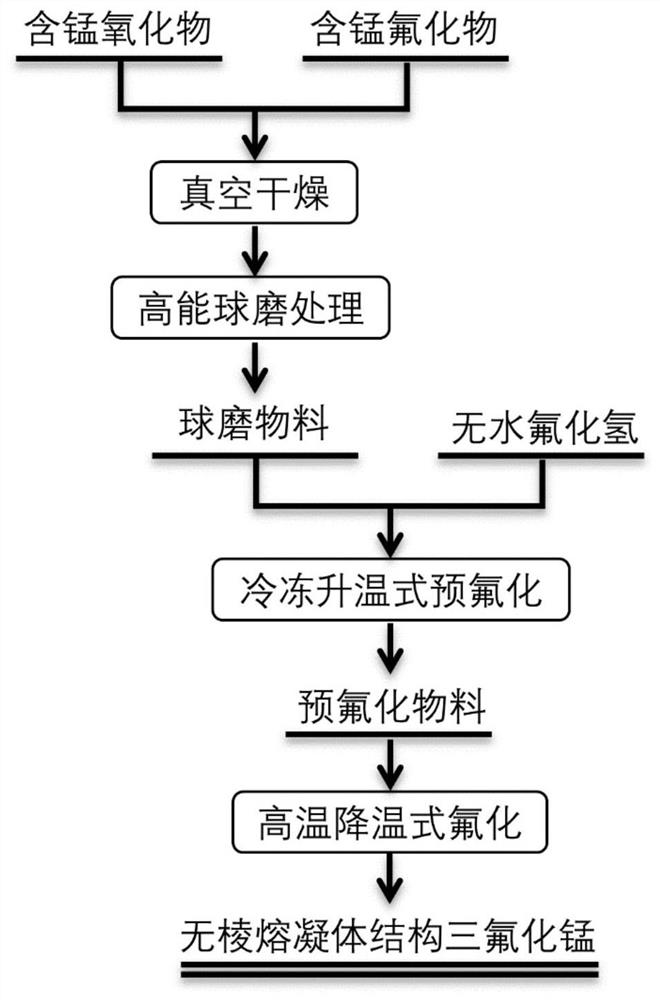

[0044] Using MnO and MnF 2 Prepare manganese trifluoride with no edge fused body structure as raw material. The preparation method is high-energy ball milling-freezing heating type pre-fluorination-high temperature cooling type fluorination process, see the process for details figure 1 .

[0045] (1) Ingredients: the raw materials MnO and MnF 2 Vacuum-dry at 150°C for 8h, weigh according to a mass ratio of 10:90, and mix evenly.

[0046] (2) High-energy ball milling: Mn 2 O 3 and MnF 2 The mixed material was transferred to a high-speed ball mill, and the ball milling speed was 1000 r / min, and the time was 10 min. After separating the product, the ball milling material was obtained.

[0047] (3) Pre-fluorination by freezing and heating type: transfer the ball-milled material into a liquid filled with frozen anhydrous hydrogen fluoride, the initial temperature of freezing of anhydrous hydrogen fluoride is -60 °C, the end temperature of heating is 40 °C, the heating rate is ...

Embodiment 2

[0051] Using MnO, Mn 2 O 3 and MnF 3 As raw material, manganese trifluoride with no ribbed fused structure is prepared.

[0052] (1) Ingredients: the raw materials MnO, Mn 2 O 3 and MnF 3 Vacuum dry at 200°C for 5h, weigh according to the mass ratio of 15:85, and mix well.

[0053] (2) High-energy ball milling: transfer the mixed powder containing manganese oxide and manganese-containing fluoride into a high-speed ball mill, the rotating speed is 700r / min, the time is 40min, and the ball-milling material is obtained after separating the product.

[0054] (3) Pre-fluorination by freezing and heating type: transfer the ball-milled material into a liquid filled with frozen anhydrous hydrogen fluoride, the initial temperature of freezing of anhydrous hydrogen fluoride is -20 °C, the end temperature of heating is 30 °C, the heating rate is 6 °C / h, and the temperature is increased. After the end, the terminal temperature was maintained to volatilize anhydrous hydrogen fluoride...

Embodiment 3

[0057] Using MnO, Mn 3 O 4 and Mn 2 F 5 As raw material, manganese trifluoride with no ribbed fused structure is prepared.

[0058] (1) Ingredients: the raw materials MnO, Mn 3 O 4 and Mn 2 F 5 Carry out vacuum drying at 100°C for 0.5h, weigh according to the mass ratio of 25:75, and mix evenly.

[0059] (2) High-energy ball milling: transfer the mixed powder of manganese oxide and manganese-containing fluoride into a high-speed ball mill, the speed is 1600r / min, the time is 20min, and the ball mill material is obtained after separating the product.

[0060] (3) Pre-fluorination by freezing and heating type: transfer the ball-milled material into a liquid filled with frozen anhydrous hydrogen fluoride, the initial freezing temperature of anhydrous hydrogen fluoride is -40 °C, the end temperature of heating is 20 °C, the heating rate is 8 °C / h, and the temperature is increased. After the end, the terminal temperature was maintained to volatilize anhydrous hydrogen fluor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com