Photoelectric coupling double-source excitation water splitting hydrogen production reactor, system and method

A photoelectric coupling and reactor technology, applied in the direction of electrolysis components, electrolysis process, electrodes, etc., can solve the problems of high cost, low conversion rate of photocatalytic hydrogen production, etc., to reduce costs, reduce losses, increase solar energy intensity and utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0130] 1. Preparation of cathode sheet:

[0131] A method for preparing a cathode sheet coated with a photoelectric catalyst, comprising the following steps:

[0132] (1), preparation of SrFe x Ti 1-x O 3-δ (STF) slurry, where 0≤x≤1, 0≤δ≤1:

[0133] The organic binder is obtained by uniformly stirring terpineol / diethylene glycol butyl ether / ethyl cellulose / lecithin in a mass ratio of 70.5 / 25 / 4 / 0.5 for 20-40 minutes;

[0134] The organic binder and the STF powder with an average particle size of 20-40 nanometers are changed according to the mass ratio in the range of 30:70-90:10, and the slurry mixer is added and stirred at a speed of 60-120rpm for 20-50min to obtain a uniform STF slurry;

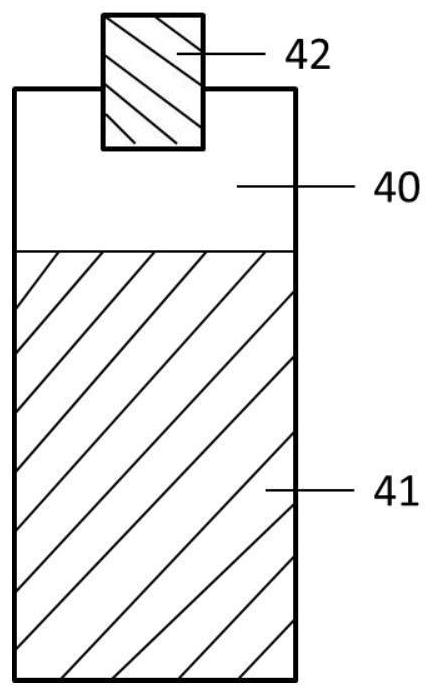

[0135] (2), the structure such as image 3 As shown in the figure, the STF paste was prepared on the conductive glass 40 by a screen printing process, with 1 / 4 of the length of the blank and a film thickness of 30-50 μm; heated at 450-500 ° C for 0.5-1 h, and then slowly lowered to roo...

Embodiment 1

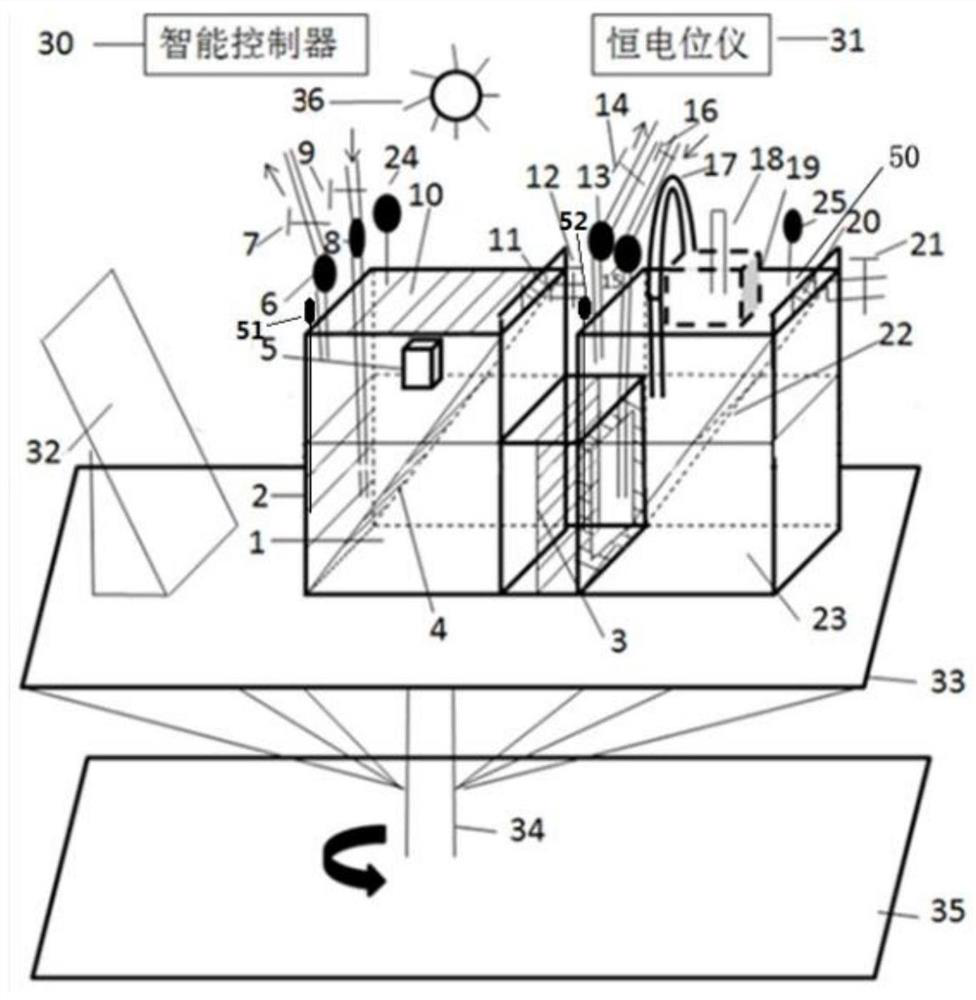

[0139] like figure 1 , Figure 5 As shown in the figure, a photoelectrically coupled dual-source excitation splitting water hydrogen production reactor is composed of an intelligent controller 30, a potentiostat 31, a cathode reactor 1, a cation exchange membrane assembly 3 and an anode reactor 23, which are connected in sequence, and the reference Electrode assembly 19 consists of:

[0140] The cation exchange membrane assembly 3 is composed of a cation exchange membrane 49 and two cation exchange membrane fixtures 48, the cation exchange membrane fixtures 48 are made of glass, and the outer sides of the two cation exchange membrane fixtures 48 are respectively connected to the cathode reactor. 1. The anode reactors 23 are connected, the cation exchange membrane clamp 48 is provided with a through cavity in the middle, and the two cation exchange membrane clamps 48 and the cation exchange membrane 49 are respectively provided with annular soft rubber gaskets between the cont...

Embodiment 2-6

[0192] It is roughly the same as Example 1, the only difference is that the solute of the cathode aqueous solution and the solute of the anode aqueous solution are different:

[0193] Solutes in the cathode aqueous solution Solute in Anode Aqueous Solution Example 2 KCl KOH Example 3 BeCl 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com