Explosion-proof control cabinet and remote control system and method for unattended point gas supply station

A remote control and remote control terminal technology, applied in the field of gasification stations, can solve the problems of error-prone data transmission, high networking costs, unstable network transmission, etc., to ensure high efficiency and stability, reduce maintenance and construction costs, The effect of reducing network installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

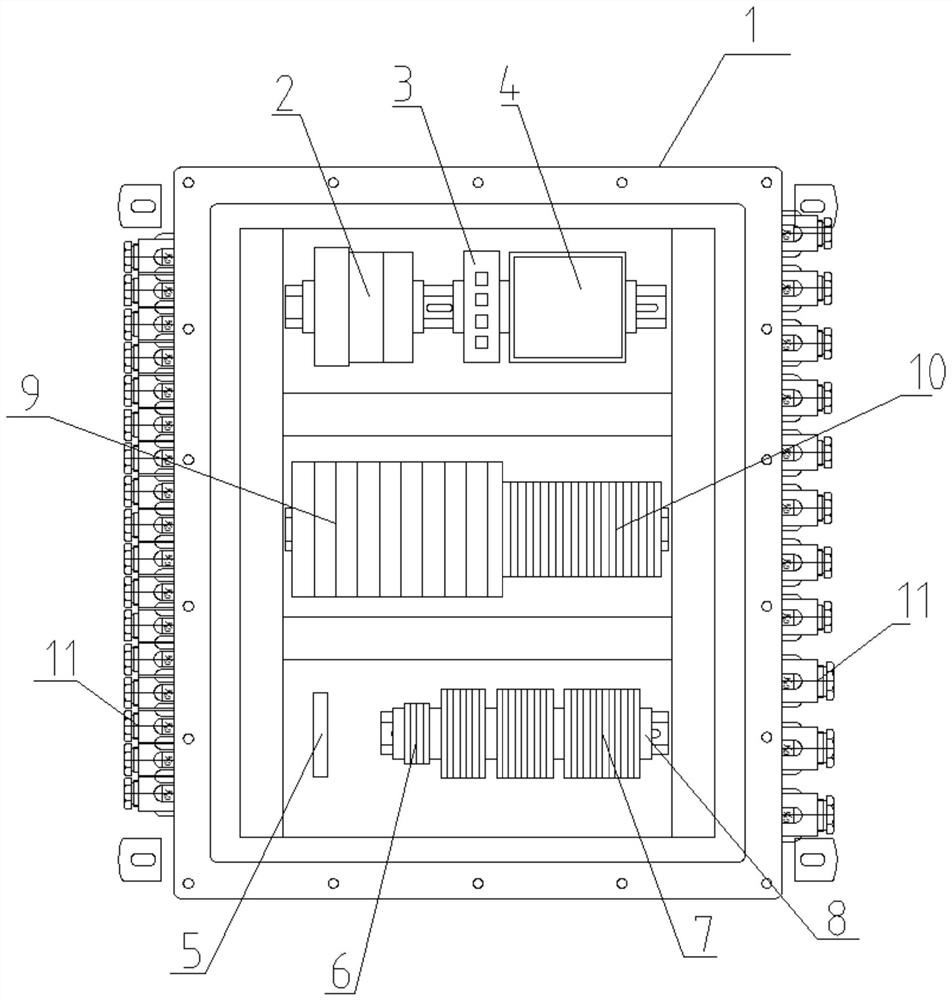

[0044] see Figure 1 to Figure 3 , the present invention provides a kind of technical scheme:

[0045] An explosion-proof control cabinet includes an explosion-proof casing 1, an on-site PLC2 (Programmable Logic Controller, programmable control device), a first VPN (Virtual Private Network, virtual private network) router 3 and a single-board computer 4; A VPN router 3 is connected, and the first VPN router 3 is connected with the single board computer 4 .

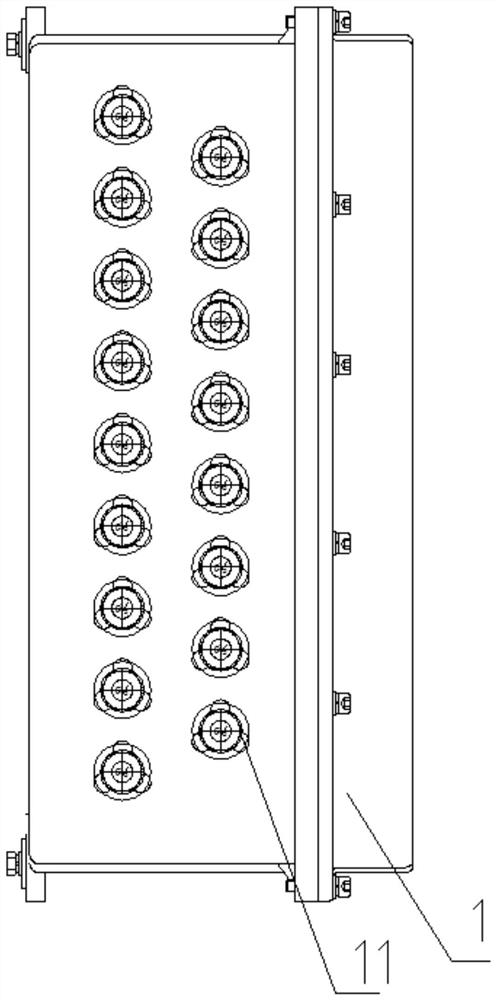

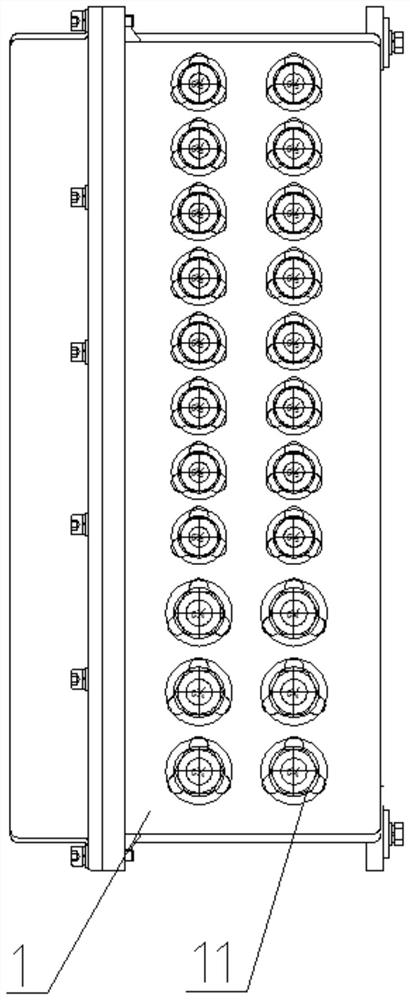

[0046] The on-site PLC2, the first VPN router 3 and the single-board computer 4 are all arranged in the explosion-proof casing 1, and the explosion-proof casing 1 is provided with a plurality of levels, and the on-site PLC2, the first VPN router 3 and the single-board computer 4 are all arranged within the topmost hierarchy.

[0047] In this embodiment, the explosion-proof control cabinet is provided with three layers, and the bottom layer is provided with a ground wire row 5, a single-layer terminal 6, a multi-layer ter...

Embodiment 2

[0052] see Figure 4 , the present invention provides a kind of technical scheme:

[0053] A remote control system for an unattended point gas supply and gasification station includes a remote control terminal, an explosion-proof control cabinet and an on-site monitoring and control component;

[0054] The remote control terminal includes a remote monitoring terminal and a second VPN router; the remote monitoring terminal is in communication connection with the second VPN router.

[0055] The explosion-proof control cabinet includes a first VPN router 3, an on-site PLC2 and a single-board computer 4; the on-site PLC2 is connected with the first VPN router 3, and the first VPN router 3 is connected with the single-board computer 4; the first VPN router 3 is connected through 5G wireless The network module is connected to the Internet; the explosion-proof control cabinet and the remote monitoring terminal are networked through VPN technology, so that the remote monitoring termi...

Embodiment 3

[0063] see Figure 5 to Figure 8 , the present invention provides a kind of technical scheme:

[0064] The present embodiment also provides a remote control method for an unattended point gas supply and gasification station, which specifically includes the following steps:

[0065] First, VPN networking is performed through the first VPN router 3 and the second VPN router, so that the explosion-proof control cabinet and the remote control terminal communicate.

[0066] Synchronous timing, the on-site PLC2 performs network timing through the SNTP (Simple Network Time Protocol) protocol, so that the on-site PLC2 time is always synchronized with the network time, which can ensure the time accuracy of all messages and avoid data confusion.

[0067] At the same time, the on-site PLC2 establishes a UDP (User Datagram Protocol, User Datagram Protocol) communication client, sends a timing message to the NTP Server (Network Time Protocol Server, network time service protocol), and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com