Multi-stage dense-phase synergistic absorption system suitable for high-concentration pollutant high-fluctuation flue gas

An absorption system and absorption tower technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of poor deacidification effect, short contact time, and low utilization rate of removers, and achieve increased treatment. volume, the effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

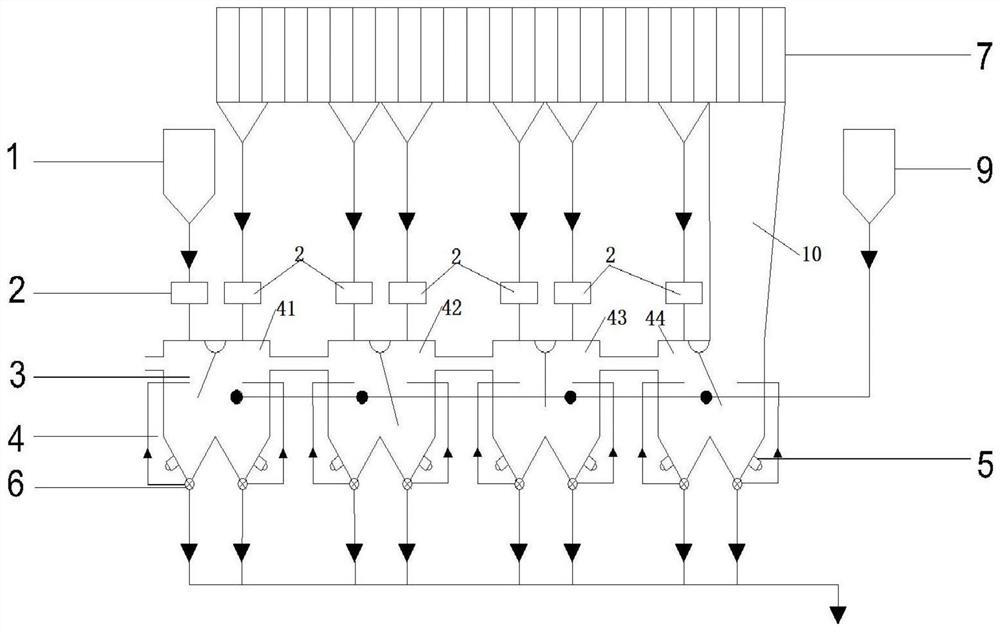

[0074] like figure 1 As shown, in this embodiment, the multi-stage absorption tower system includes four absorption towers 4 , specifically a first-stage absorption tower 41 , a second-stage absorption tower 42 , a third-stage absorption tower 43 and a fourth-stage absorption tower 44 . Each stage of the absorption tower includes an air inlet and an air outlet, which are connected in series from the first-stage absorption tower to the fourth-stage absorption tower, that is, the air outlet of the first-stage absorption tower is connected to the air inlet of the second-stage absorption tower, and the second-stage The air outlet of the absorption tower is connected to the air inlet of the three-stage absorption tower.

[0075] The multistage absorption tower system includes a new ash bin 1 for storing the deacidification agent. Described deacidification agent comprises calcium carbonate, calcium oxide, calcium hydroxide, sodium carbonate, the mixture of two or more substances in...

Embodiment 2

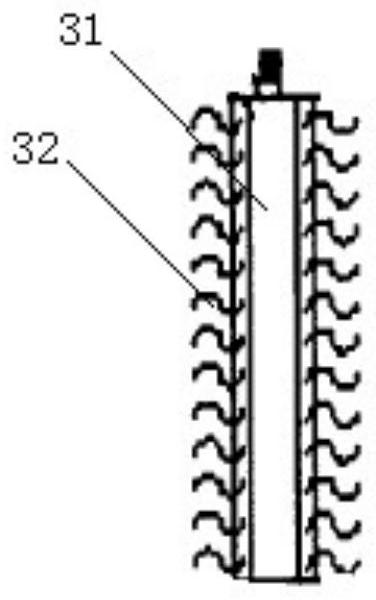

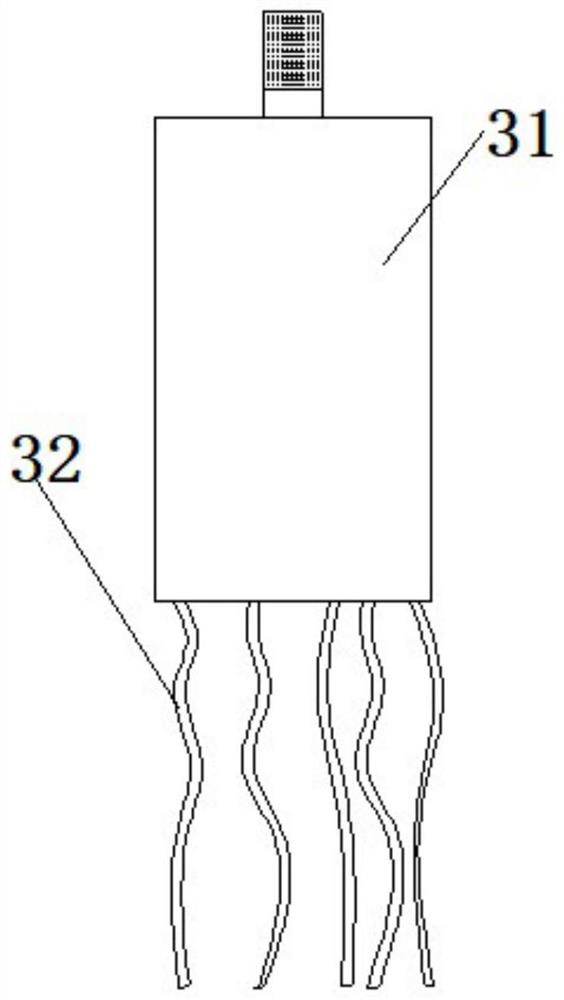

[0085] The difference from Example 1 is that the setting of the stirring device is different. Each stage of the tower body is provided with a co-gravity flow area and a counter-gravity flow area, and the co-gravity flow area is equipped with a vertical stirring device. The stirring rate of the device is 0~910r / min, and the stirring radius is 0~4.5m. Fluctuation, frequency conversion dynamically adjusts the speed to match the change of flue gas; there is a horizontal stirring device in the counter-gravity flow area, the stirring speed of the device is 0 ~ 570r / min, the stirring radius is 0 ~ 3m, the frequency conversion dynamically adjusts the speed to match the change of material circulation .

[0086] The system of Embodiment 1 is adopted below (the number of absorption towers varies), and is described in conjunction with specific examples.

experiment example 1

[0087] Experimental example 1, using a 4-stage absorption tower, the acid gases HF, HCl, SO in the original flue gas2 As shown in the table, the water content of flue gas is 40%, 200 mesh calcium hydroxide is used as deacidification agent (moisture content 8%), the height of the tower is 12m, the length of the spoiler component is 5.6m, and the inclination angle is +65 °, the purification efficiency is above 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com