Intermetallic compound catalyst and preparation method thereof

An intermetallic compound and catalyst technology, applied in the field of intermetallic compound catalysts and their preparation, can solve the problems of reduced durability and catalytic activity, easy melting, performance and durability reduction, etc., and achieve the effect of improving catalyst performance and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

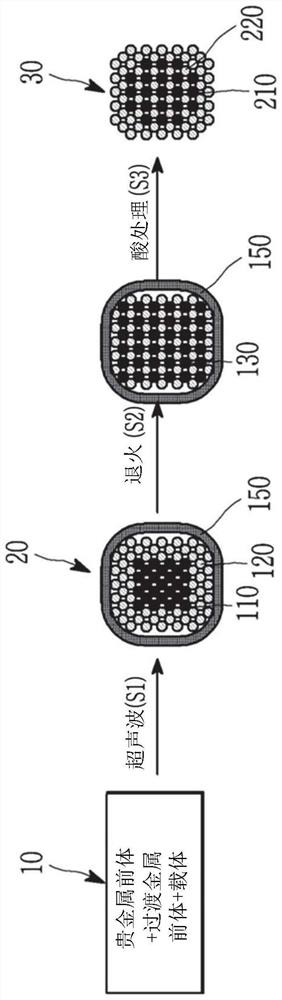

[0075] The method of preparing the intermetallic compound catalyst 30 according to the embodiment provides the core-shell particles 20 including the transition metal oxide coating 150 in one process using ultrasonication, so that the process can be simplified to save costs.

[0076] The core-shell particles 20 are then annealed to provide intermetallic particles including the transition metal oxide coating 150 (S2).

[0077] The atoms of the noble metal and the transition metal are regularly arranged by the annealing process, and the ratio of the transition metal core 110 is decreased, thereby preparing the intermetallic compound particles 130 . The intermetallic compound particles are alloys of noble metals and transition metals, which are intermetallic compound alloys in which noble metal atoms and transition metal atoms are regularly arranged.

[0078] Since the transition metal oxide coating 150 inhibits particle growth, the size of the intermetallic compound particles 130...

Embodiment

[0099] Hereinafter, specific embodiments of the present invention are described. However, the examples described below are for illustrative purposes only, and the scope of the present invention is not limited thereto.

[0100] Preparation Example: Preparation of Intermetallic Compound Catalyst

[0101] Example

[0102] Put Pt(acac) 2 , Fe(acac) 3 and porous carbon support (Vulcan XC72) were added to ethylene glycol to prepare a solution of the precursor mixture, and then 100 mL of the precursor mixture was sonicated using a Tip-type ultrasonic wave (Sonic & Materials, model VC-500, 30% amplitude, 13 mm solid probe, 20 kHz). The solution was subjected to ultrasonic irradiation at an output of 150 W under an argon atmosphere for 3 hours to provide core-shell particles comprising transition metal oxide coatings.

[0103] At this time, the addition amount of the noble metal precursor and the transition metal precursor is adjusted so that the atomic ratio of the noble metal a...

experiment example 1

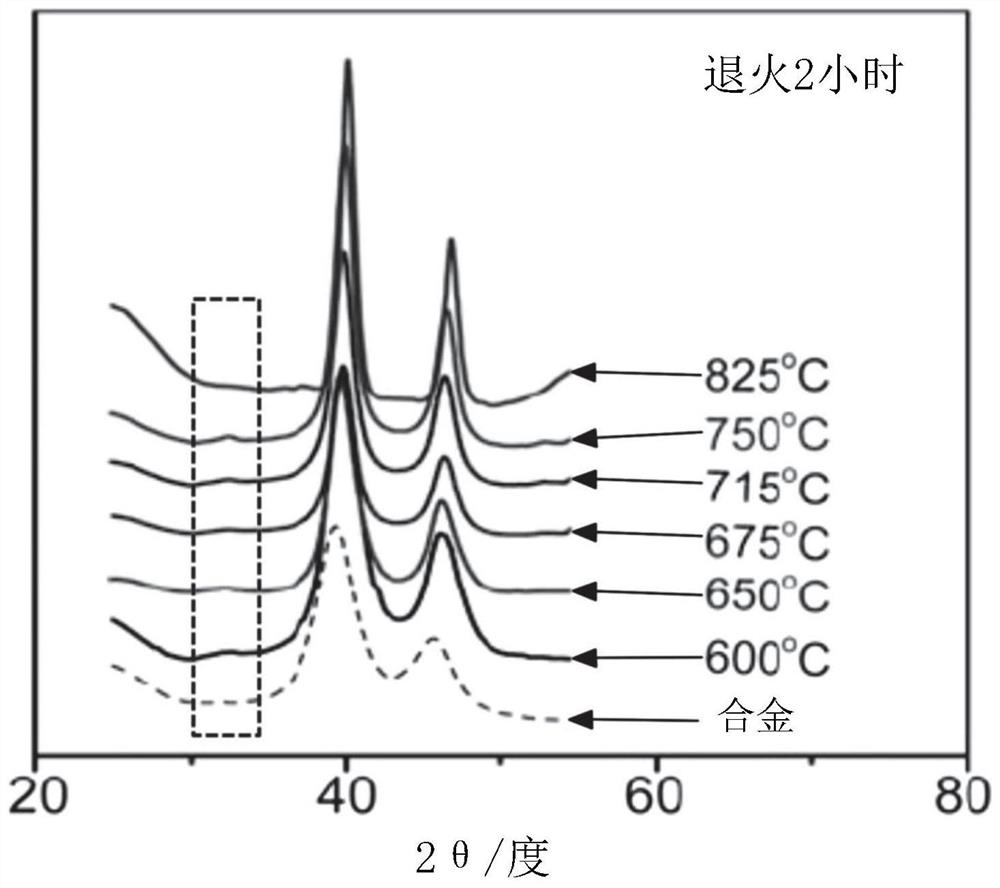

[0109] Experimental Example 1: XRD analysis according to the annealing temperature of the intermetallic compound catalyst prepared in the comparative example

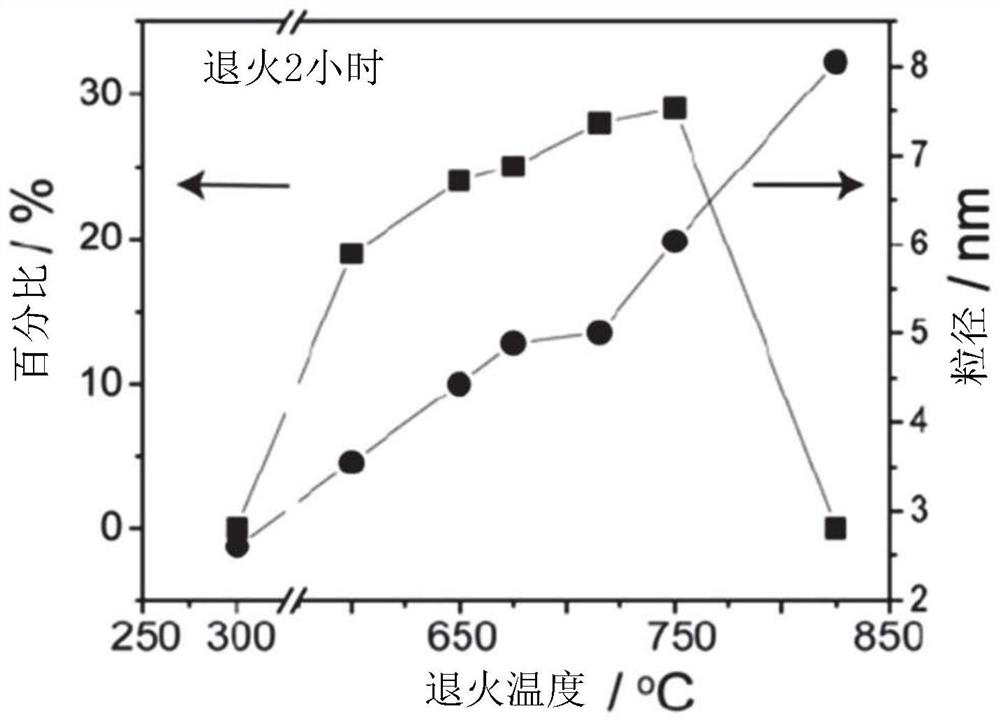

[0110] In-situ XRD analysis was performed on the intermetallic compound catalyst prepared in the comparative example, and the results are shown in figure 2 middle. In addition, the degree of atomic arrangement order of the intermetallic compound catalysts prepared in Examples and Comparative Examples was measured, and the results are shown in image 3 middle. Figure 4 The phase transition diagram of the intermetallic compound catalyst prepared in the comparative example is shown.

[0111] In the case of the comparative example, since the annealing gas directly transfers heat in the method of producing intermetallic compound particles without introducing a coating layer for particle size control, the effective heat transfer rate is very fast compared to the examples.

[0112] as in figure 2 As shown in the XRD pat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com