High-vacuum low-temperature whole kelp drying system based on MVR

A drying system and high-vacuum technology, applied in the modern marine field, can solve problems such as easy adhesion, low quality, low efficiency, etc., achieve uniform temperature distribution, solve low quality, and improve drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

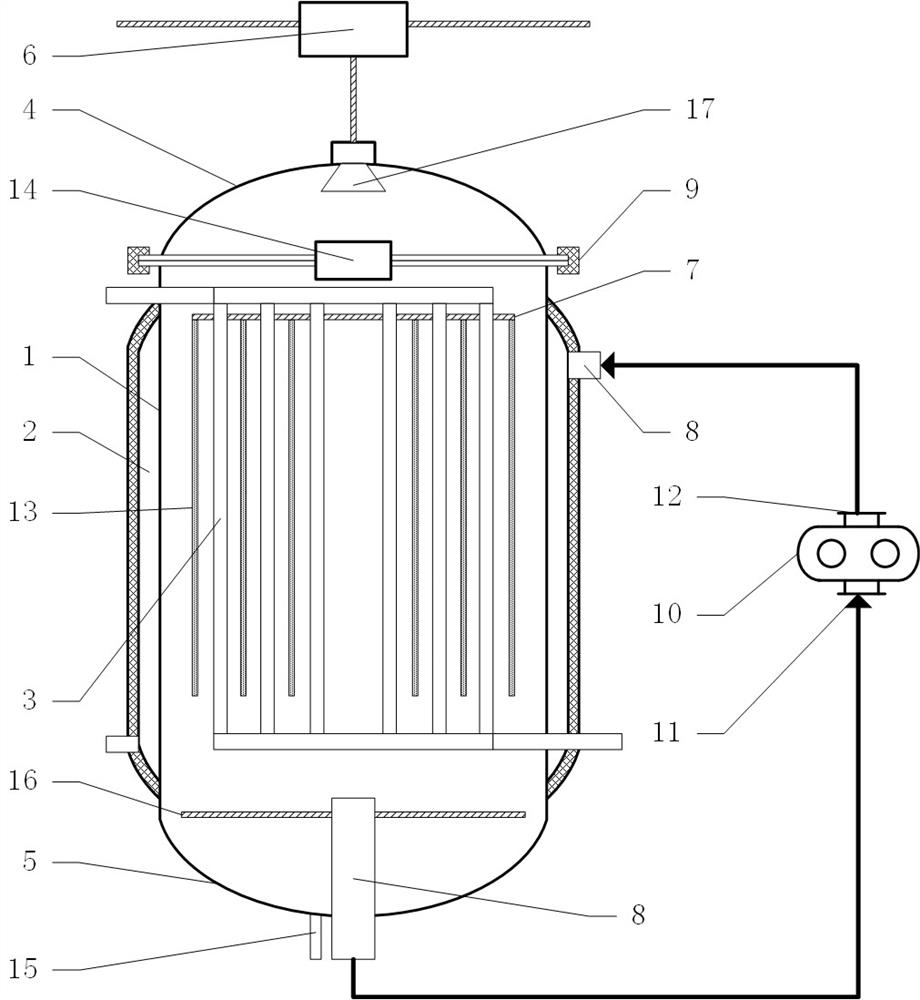

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

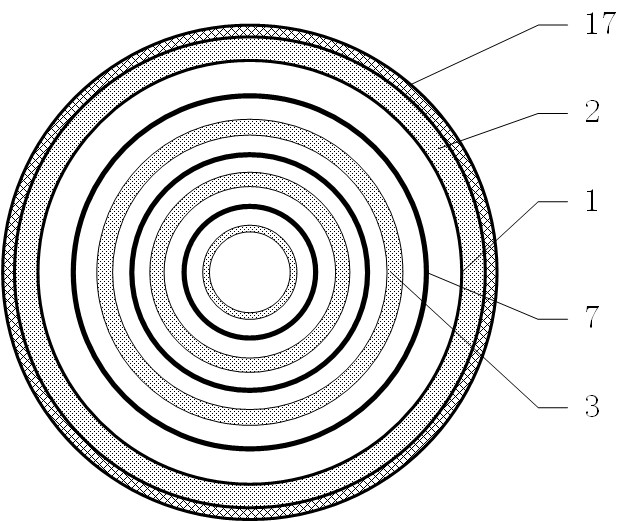

[0029] like figure 1 Shown is the schematic diagram of the whole kelp drying system based on MVR at high vacuum and low temperature, figure 1 , the MVR-based high-vacuum-low-temperature whole kelp drying system includes a tank (1), a jacket (2), a coil (3), an upper head (4), and a lower head (5) , suspension mechanism (6), suspension mechanism (7), exhaust port (8), locking mechanism (9), steam compressor (10), air inlet (11), air outlet (12), kelp ( 13), axial flow fan (14), water outlet (15), partition plate (16), insulation layer (17).

[0030] The suspension mechanism (6) adopts traveling vehicle. When the system is working, the upper head (4) is firstly lifted by the suspension mechanism (6), and moved horizontally to the nearby loading site. The operator or automatic equipment removes the kelp (13) Suspended on the suspension mechanism (7), the suspension me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com