Production system and method of acetaminophen

A paracetamol and production system technology, applied in the field of paracetamol production systems, can solve the problems of affecting the quality of acetaminophen, easy oxidation, discoloration and deterioration, and many aminophenol impurities, so as to save steam consumption and be difficult to oxidize. The effect of discoloration and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

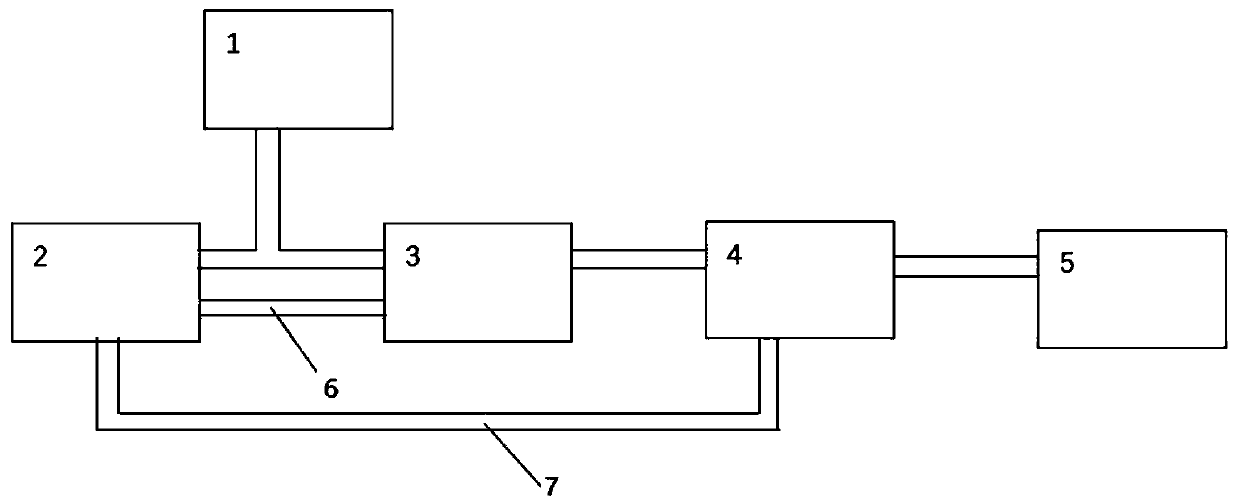

[0062] The reaction system that the production method of paracetamol of the present embodiment adopts is as figure 1 shown.

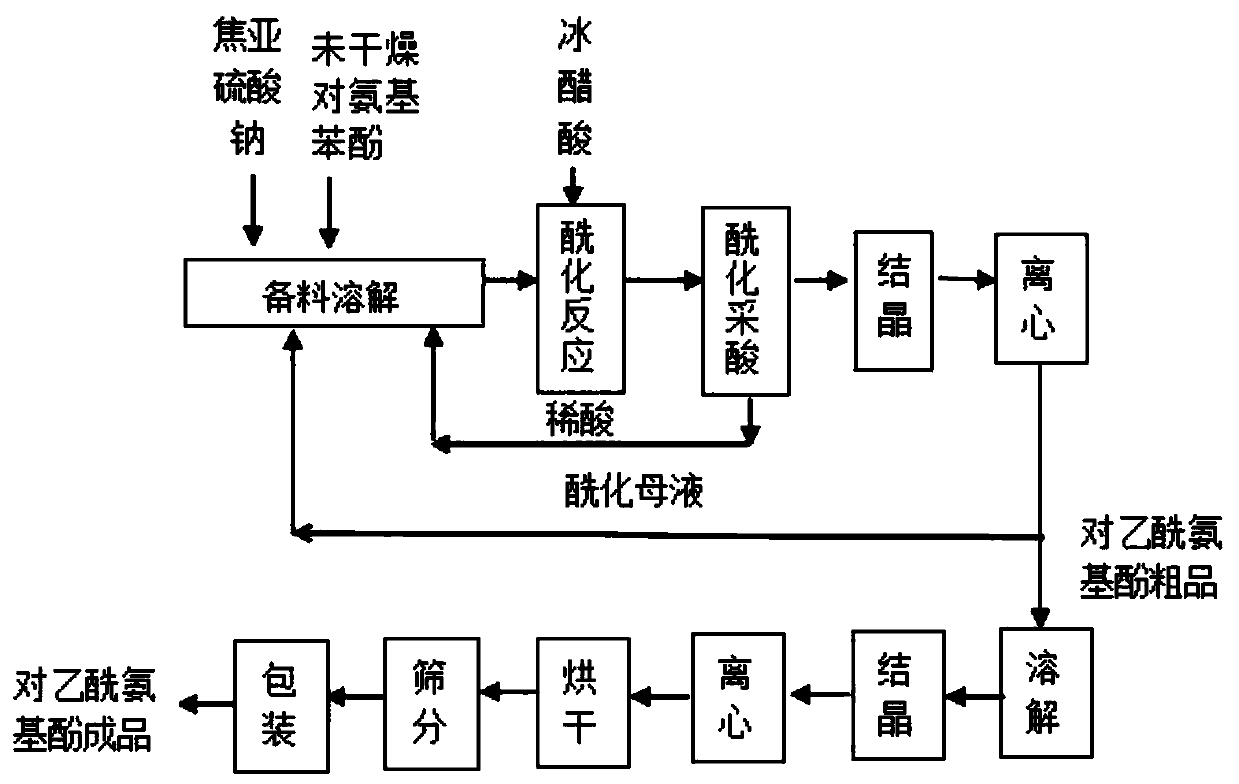

[0063] The production method of the present embodiment comprises the following steps:

[0064] (1) Preparation and dissolution: 1900kg of p-aminophenol with a content of 96% and a purity of 99.62%, 2500kg of dilute acid (glacial acetic acid aqueous solution with a mass concentration percentage of 58%), and 9.5kg of sodium metabisulfite (mass ratio: 1:1.32:0.005) Put it into the preparation material dissolving kettle, mix evenly, obtain the raw material mixed liquid, set aside.

[0065] (2) Acylation reaction: the raw material mixture is transported to the acylation kettle by a pump, (the air in the pipeline, the dissolution kettle, and the acylation kettle is replaced by nitrogen) and 1253kg of glacial acetic acid (the mole of undried p-aminophenol and glacial acetic acid) is added Ratio of 1:1.2) was slowly heated to about 100°C and refluxed for 3 ho...

Embodiment 2

[0073] The reaction system that the production method of paracetamol of the present embodiment adopts is as figure 1 shown.

[0074] The production method of the present embodiment comprises the following steps:

[0075] (1) Preparation and dissolution: 1900kg of p-aminophenol with a content of 97% and a purity of 99.78%, 2500kg of dilute acid (glacial acetic acid aqueous solution with a mass concentration percentage of 50%), and 9.5kg of sodium metabisulfite (mass ratio: 1:1.32:0.005) Put it into the preparation material dissolving kettle, mix evenly, obtain the raw material mixed liquid, set aside.

[0076](2) Acylation reaction: the raw material mixture is transported to the acylation kettle by a pump, (the air in the pipeline, the dissolution kettle, and the acylation kettle is replaced by nitrogen) and 1464kg of glacial acetic acid (the mole of undried p-aminophenol and glacial acetic acid) is added Ratio of 1:1.3) was slowly heated to about 110°C and refluxed for 3 hou...

Embodiment 3

[0082] The reaction system that the production method of paracetamol of the present embodiment adopts is as figure 1 shown.

[0083] The production method of the present embodiment comprises the following steps:

[0084] (1) Prepare materials and dissolve: 1900kg of p-aminophenol with a content of 96.5% and a purity of 99.68%, 2500kg of dilute acid (glacial acetic acid aqueous solution with a mass concentration percentage of 64%), and 9.5kg of sodium metabisulfite (mass ratio: 1:1.32:0.005) Put it into the preparation material dissolving kettle, mix evenly, obtain the raw material mixed liquid, set aside.

[0085] (2) Acylation reaction: the raw material mixture is transported to the acylation kettle by a pump, (the air in the pipeline, the dissolution kettle, and the acylation kettle is replaced by nitrogen) and 1464kg of glacial acetic acid (the mole of undried p-aminophenol and glacial acetic acid) is added Ratio of 1:1.4) was slowly heated to about 110°C, refluxed for 3h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com