Diamond carbon fiber composite material with high bonding strength and preparation method thereof

A technology of bonding strength and composite materials, applied in chemical instruments and methods, lamination auxiliary operations, lamination, etc., can solve problems such as inability to meet the heat dissipation requirements of high-power electronic devices, achieve high bonding strength, resist thermal shock, and improve The effect of binding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

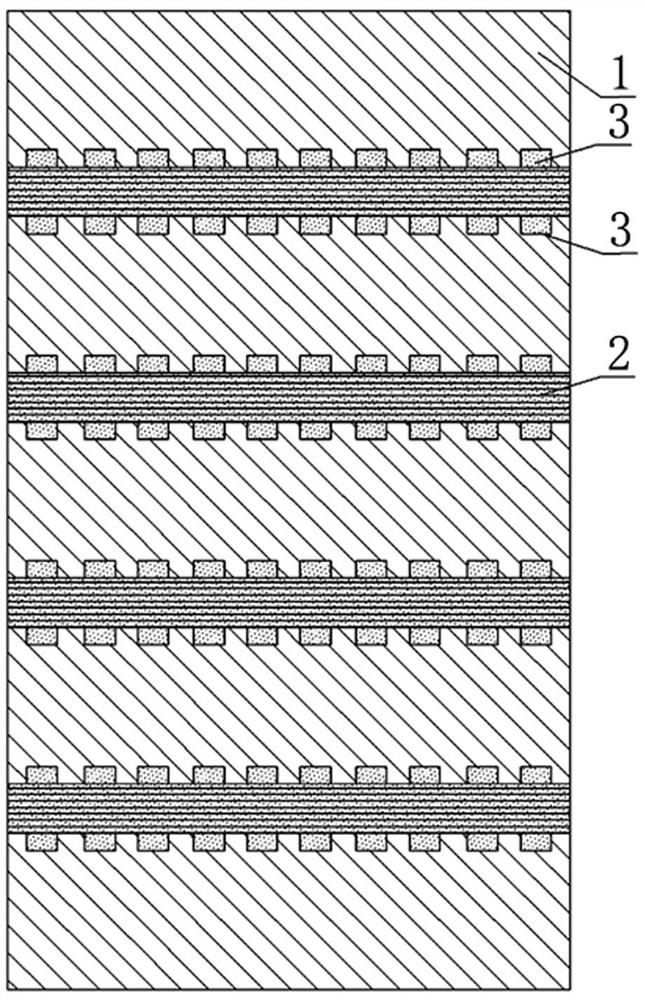

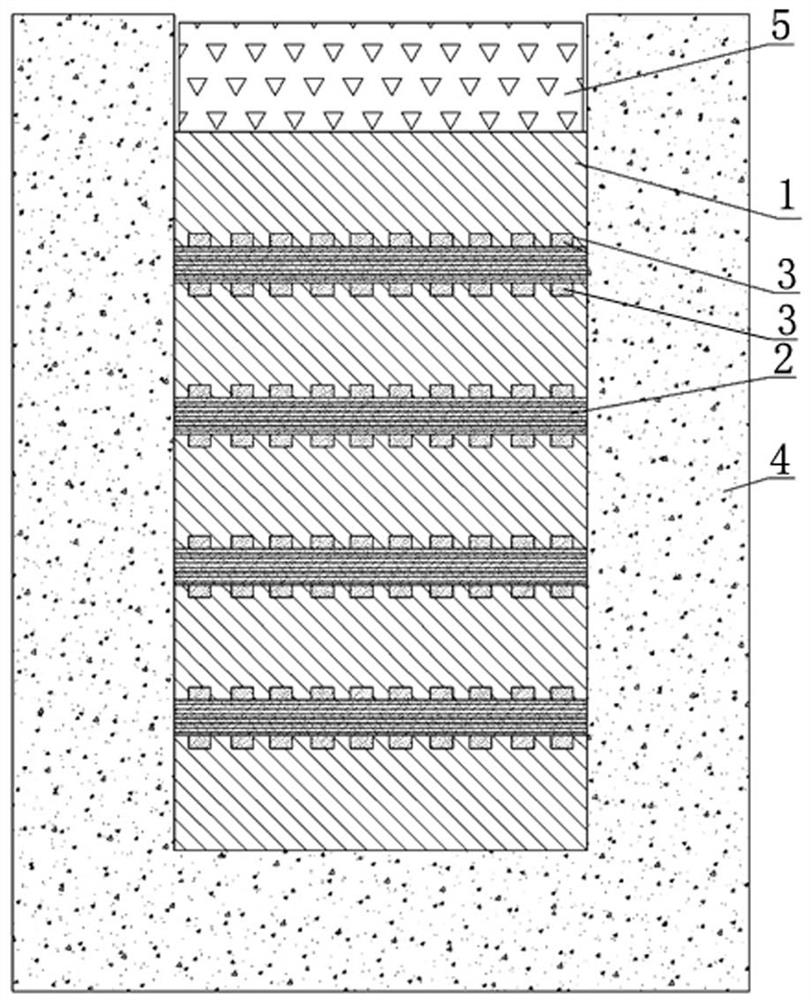

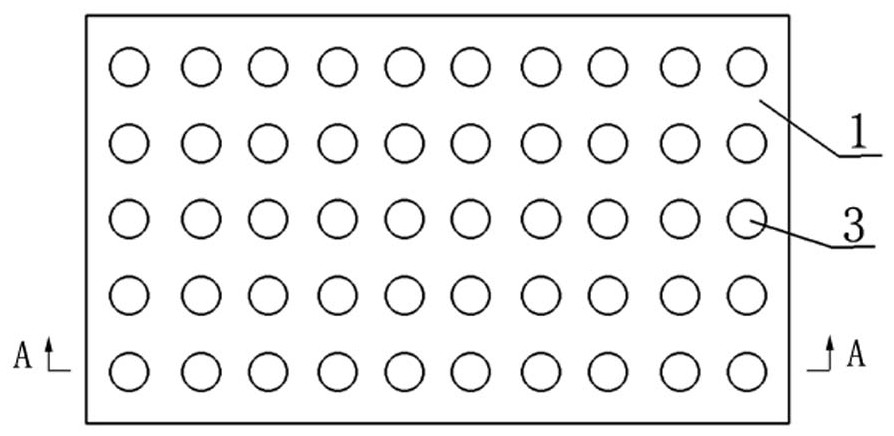

[0039] A high-bonding strength diamond carbon fiber composite material and a preparation method thereof are formed by stacking self-supporting diamond diaphragms 1 and carbon fiber layers 2 alternately arranged in sequence, and the top layer and the bottom layer are both self-supporting diamond diaphragms 1; The number of layers of diamond diaphragm 1 is three, and the length, width and thickness of each layer are 10 mm × 5 mm × 1 mm, and the number of layers of carbon fiber layer 2 is two, and the length, width and thickness of each layer are 10 mm × 5 mm×0.3 mm; the bottom surface of the top layer self-supporting diamond diaphragm 1, the top surface of the bottom layer self-supporting diamond diaphragm 1 and the top and bottom surfaces of the middle layer self-supporting diamond diaphragm 1 have been textured, such as Figure 5 shown.

[0040] The specific preparation method of the above-mentioned high bonding strength diamond carbon fiber composite material comprises the fo...

Embodiment 2

[0049] A high-bonding strength diamond carbon fiber composite material and a preparation method thereof are formed by stacking self-supporting diamond diaphragms 1 and carbon fiber layers 2 alternately arranged in sequence, and the top layer and the bottom layer are both self-supporting diamond diaphragms 1; The number of layers of diamond diaphragm 1 is six, and the length, width and thickness of each layer are 15 mm × 15 mm × 0.6 mm, and the number of layers of carbon fiber layer 2 is five, and the length, width and thickness of each layer are 15 mm × 15 mm×0.15 mm; the bottom surface of the top layer self-supporting diamond diaphragm 1, the top surface of the bottom layer self-supporting diamond diaphragm 1, and the top and bottom surfaces of the middle layers of self-supporting diamond diaphragm 1 are all textured, such as Image 6 shown.

[0050] The specific preparation method of the above-mentioned high bonding strength diamond carbon fiber composite material comprises ...

Embodiment 3

[0059] A high-bonding strength diamond carbon fiber composite material and a preparation method thereof are formed by stacking self-supporting diamond diaphragms 1 and carbon fiber layers 2 alternately arranged in sequence, and the top layer and the bottom layer are both self-supporting diamond diaphragms 1; The number of layers of diamond diaphragm 1 is ten, and the length, width and thickness of each layer are 20 mm × 15 mm × 0.3 mm, and the number of layers of carbon fiber layer 2 is nine, and the length, width and thickness of each layer are 20 mm × 15 mm×0.1 mm; the bottom surface of the top layer self-supporting diamond diaphragm 1, the top surface of the bottom layer self-supporting diamond diaphragm 1, and the top and bottom surfaces of the middle layers of self-supporting diamond diaphragm 1 are all textured, such as Figure 7 shown.

[0060] The specific preparation method of the above-mentioned high bonding strength diamond carbon fiber composite material comprises ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Parallelism | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com