A preparation method of a thermal barrier coating containing a double-layer structural bonding layer

A technology of thermal barrier coating and double-layer structure, which is applied in the direction of coating, superimposed layer plating, metal material coating process, etc., can solve the problems of low porosity and coating thermal conductivity, and reach the service temperature High, anti-diffusion, high operating temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

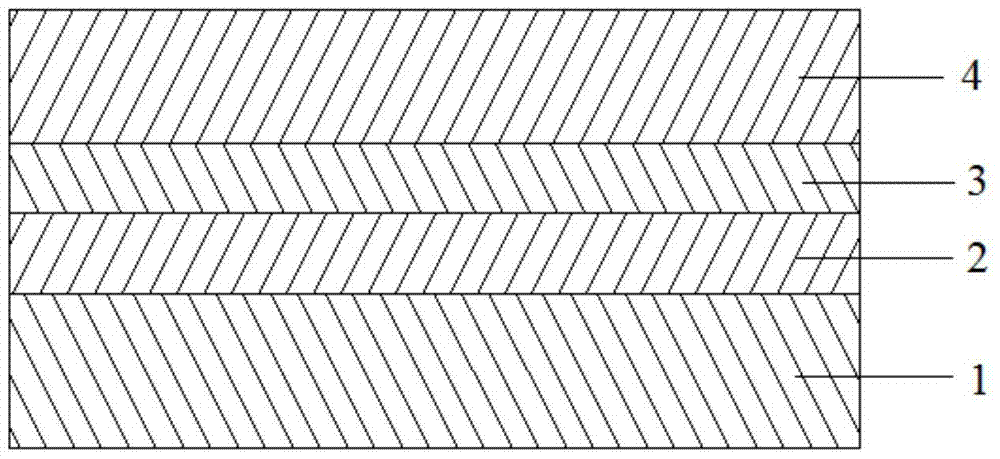

[0032] A preparation method of a thermal barrier coating containing a double-layer structure adhesive layer, using the following steps:

[0033] (1) Degrease and sandblast the metal substrate in turn;

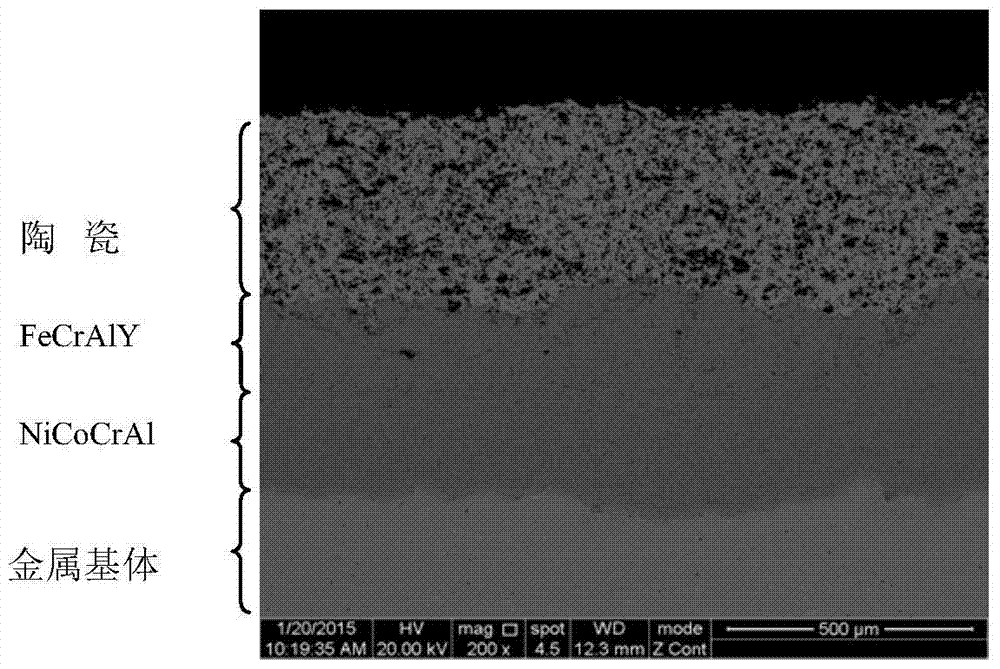

[0034] (2) by low-pressure plasma spraying, high-speed oxygen flame spraying or high-speed compressed air flame spraying on the metal substrate to prepare the first bonding layer with the composition NiCoCrAlY;

[0035] (3) prepare the second bonding layer of FeCrAlY on the first bonding layer by atmospheric plasma spraying, high-speed oxygen flame spraying or high-speed compressed air flame spraying;

[0036] (4) The ceramic layer is deposited on the double-layer adhesive layer by atmospheric plasma spraying, high-speed oxygen flame spraying, solution plasma spraying or electron beam physical vapor deposition technology, and the composition of the ceramic layer is 6-8wt% Y 2 O 3 Stable ZrO 2 or RE 2 Zr 2 O 7 , where RE is a rare earth element.

[0037]The sandblasting p...

Embodiment 1

[0045] A preparation method of a thermal barrier coating containing a double-layer structure adhesive layer, using the following steps:

[0046] (1) First, use Al with a particle size of 16 to 120 meshes for the metal substrate 1 2 O 3 , sandblast the substrate to obtain uniform surface roughness;

[0047] (2) When using low-pressure plasma spraying in step (2), the distance between the spray gun and the metal substrate is 100-250 mm, the moving speed of the spray gun is 300-1000 mm / s, the powder feeding rate is 10-70 g / min, and the powder feeding air flow is 0.5~1.2L / min, the voltage range is 100~180V, the spraying current range is 200~250A, and the vacuum degree is less than 20KPa. A first bonding layer 2 is introduced on the metal substrate 1. The composition of the bonding layer is NiCoCrAlY. In this method, the ceramic particles are heated and melted or semi-melted by a high-temperature plasma beam, and then quickly sprayed onto the surface of the substrate to form a la...

Embodiment 2

[0052] A preparation method of a thermal barrier coating containing a double-layer structure adhesive layer, using the following steps:

[0053] (1) Degrease and sandblast the metal substrate in turn. The sandblasting pressure used in the sandblasting treatment is 0.1MPa, and the main component of the sandblasting particles is Al. 2 O 3 , the particle size is 16 meshes;

[0054] (2) The first bonding layer composed of NiCoCrAlY was prepared on the metal substrate by low-pressure plasma spraying. During low-pressure plasma spraying, the distance between the spray gun and the metal substrate was 100 mm, the moving speed of the spray gun was 300 mm / s, and the powder feeding rate was 10 g / s min, the powder feeding airflow is 0.5L / min, the voltage range is 100V, the spray current range is 200A, and the vacuum degree is less than 20KPa;

[0055] (3) depositing a second adhesive layer on the first adhesive layer by atmospheric plasma spraying, and the composition of the adhesive la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com