Electrochemical device applied to oily wastewater treatment and treatment method thereof

A waste water treatment and electrochemical technology, which is applied in chemical instruments and methods, water/sewage treatment, oxidized water/sewage treatment, etc., can solve problems such as poor demulsification effect, and achieve improved service life, large coverage, and improved filtration effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

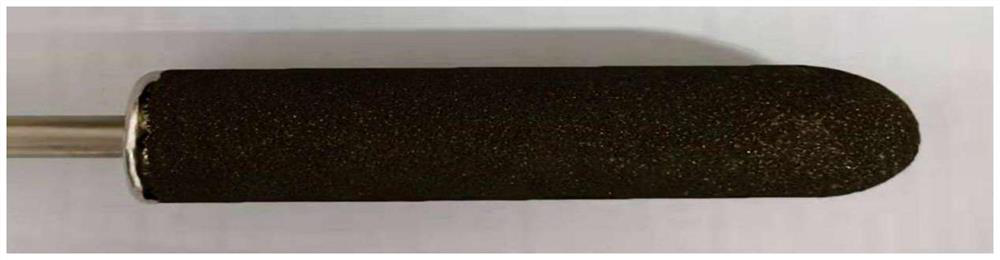

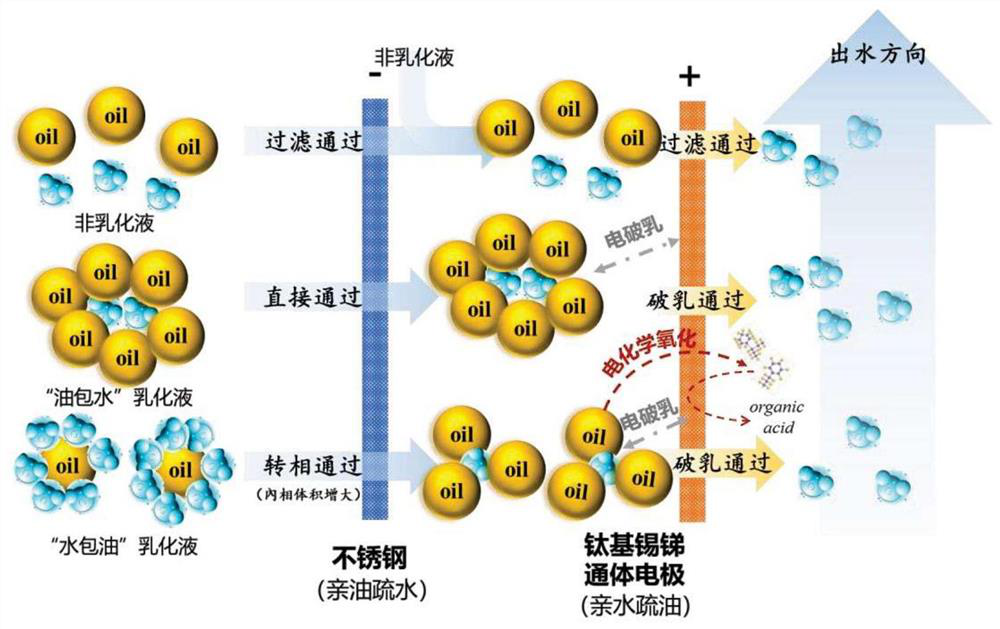

[0103] Using a titanium-based antimony-doped tin dioxide microporous through-body electrode applied to the treatment of oily wastewater of the present invention as the anode, and using the microporous stainless steel tube as the cathode to treat the oil and gas exploitation and production wastewater, the following steps are included:

[0104] Step 1. Prepare antimony-doped tin dioxide microporous through-body electrode, and the preparation steps are as follows:

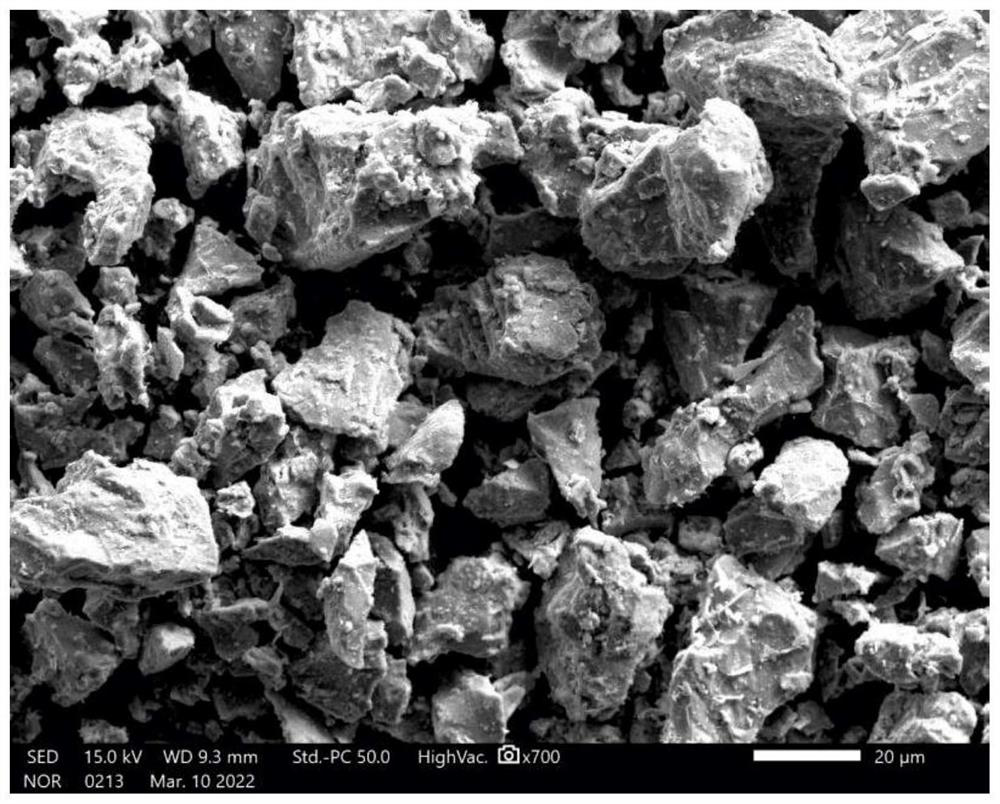

[0105] The first step: boil the titanium foam with a thickness of 5mm in oxalic acid with a volume concentration of 30%, rinse with deionized water, alkali rinse with NaOH solution of 20% concentration and rinse with deionized water, then soak in deionized water. 12h to remove the oil stain and oxide layer on the surface of foam titanium, and dry it under 40 holes; configure a sufficient amount of mixed solution of antimony trichloride (16mg / L) and citric acid (40mg / L) and tin tetrachloride (15mg / L) / L) and sulfuric a...

Embodiment 2

[0120] Using a titanium-based antimony-doped tin dioxide microporous through-body electrode applied to the treatment of oily wastewater of the present invention as the anode, and using the microporous stainless steel tube as the cathode to treat a certain food processing wastewater, the following steps are included:

[0121] Step 1: Prepare a microporous antimony-doped tin dioxide microporous through-body electrode. The specific preparation steps are as follows:

[0122] The first step: the titanium foam with a thickness of 3mm is boiled in oxalic acid with a volume concentration of 10%, rinsed with deionized water, alkali washed with a 10% concentration of NaOH solution and rinsed with deionized water, and then soaked in deionized water. 12h to remove the oil stain and oxide layer on the surface of foamed titanium, and dry it at 35 °C; configure a sufficient amount of mixed solution of antimony trichloride (12mg / L) and citric acid (35mg / L) and tin tetrachloride (10mg / L) / L) a...

Embodiment 3

[0134] Using a titanium-based antimony-doped tin dioxide microporous through-body electrode applied to the treatment of oily wastewater of the present invention as the anode, and using the microporous stainless steel tube as the cathode to treat a certain machining wastewater, the following steps are included:

[0135] Step 1: Prepare a microporous antimony-doped tin dioxide microporous through-body electrode. The specific preparation steps are as follows:

[0136] The first step: boil the titanium foam with a thickness of 3mm in oxalic acid with a volume concentration of 20%, rinse with deionized water, alkali rinse with 15% concentration of NaOH solution and rinse with deionized water, then soak in deionized water. 12h to remove the oil stain and oxide layer on the surface of foamed titanium, and dry it at 30 °C; configure a sufficient amount of mixed solution of antimony trichloride (14mg / L) and citric acid (36mg / L) and tin tetrachloride (10mg / L) / L) and sulfuric acid (20mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com