Preparation method of bromoacetonitrile

A technology of bromoacetonitrile and chloroacetonitrile, applied in the synthesis field of bromoacetonitrile, can solve the problems of high price, high risk, poor safety, etc., and achieve the effects of less waste discharge, green process route, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

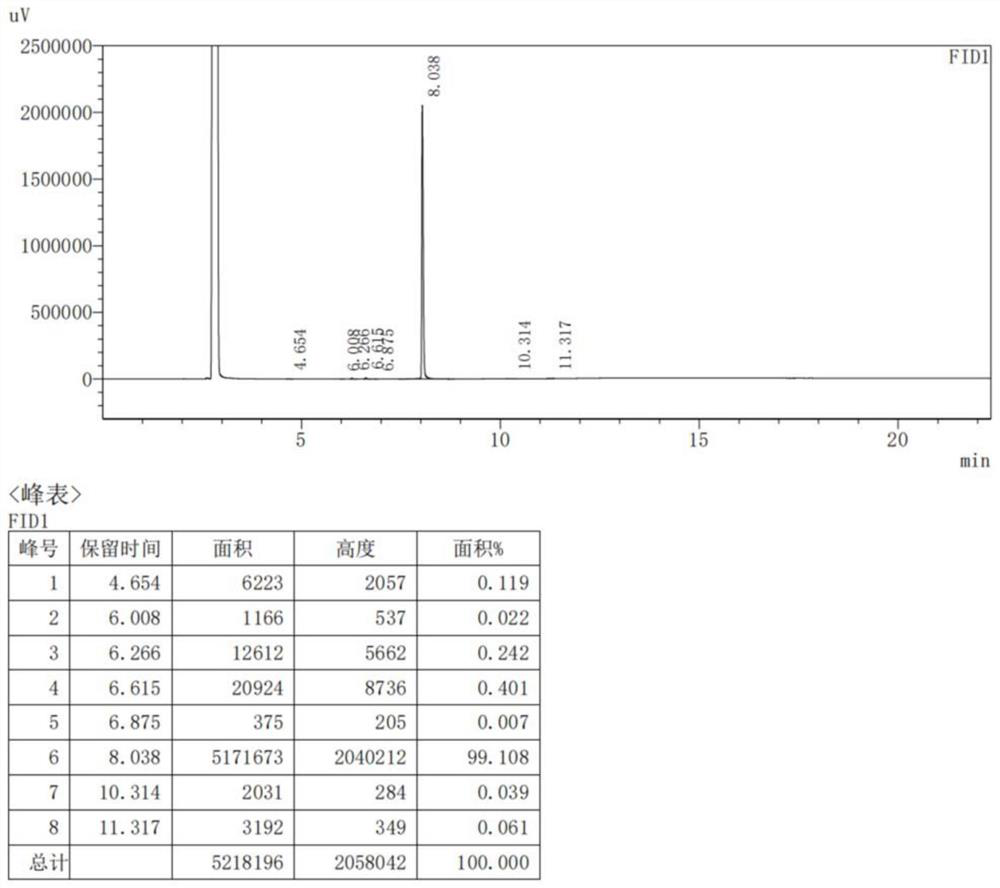

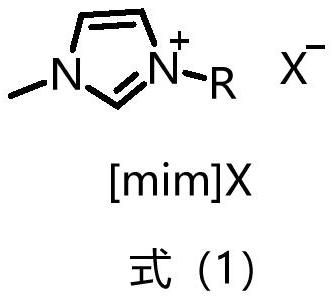

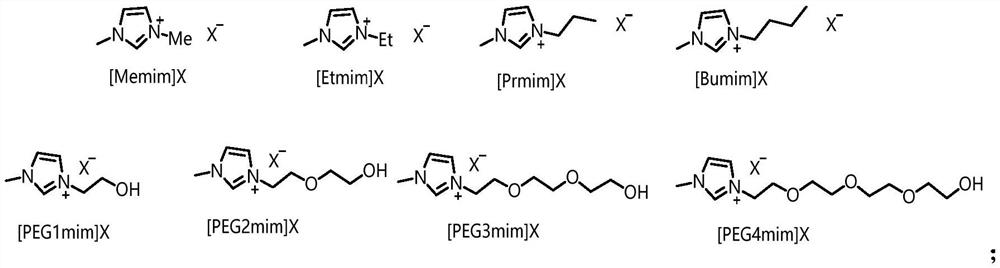

[0043] (1) In a 5L four-necked flask, add methanol 2.1Kg, chloroacetonitrile 1.0Kg, catalyst [Prmim]Cl 2.1g (0.1mol%), then add sodium bromide 1.5Kg (1.1eq), stir rapidly, and heat up to 75 The reaction was carried out at °C for 10 hours. After the reaction was completed, GC was tested, the conversion rate was 98.1%, and the selectivity was 99.1%.

[0044] (2) reaction system is lowered to room temperature, filtered, washed filter cake with methanol 200g, the filtrate was merged, and methanol was recovered by atmospheric distillation for subsequent reaction, and the heavy component was subjected to vacuum distillation to obtain 1.44Kg of bromoacetonitrile, yield 90.6%, purity 99.2%. The catalyst remaining at the bottom of the rectification tank is recovered and applied mechanically.

Embodiment 2

[0046] The target product bromoacetonitrile was prepared according to the same method as in Example 1, except that the catalyst in step (1) was [Prmim]Br.

Embodiment 3

[0048] The target product bromoacetonitrile was prepared according to the same method as in Example 1, except that the catalyst in step (1) was [Memim]Br.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com