Low-smoke, non-dripping, halogen-free and flame-retardant polycarbonate composition as well as preparation method and application thereof

A flame-retardant polycarbonate and polycarbonate technology are applied in the field of low-smoke, drip-free, halogen-free, flame-retardant polycarbonate compositions and their preparation fields, and can solve the problem of large smoke generation and drip resistance of flame-retardant polycarbonates. problems such as poor drop performance, to achieve the effect of high flame retardant performance, high fluidity, and improved tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The present invention also provides a method for preparing any of the above-mentioned low-smoke, drip-free, halogen-free flame-retardant polycarbonate compositions, comprising the following steps:

[0058] The components are kneaded and granulated.

[0059] In a specific embodiment of the present invention, the kneading and granulation comprises using a twin-screw extruder.

[0060] In a specific embodiment of the present invention, the preparation of the auxiliary agent includes: pre-mixing polycarbonate with a melt index of 10-12, an anti-drip agent, a mold release agent and a heat stabilizer at a low speed for 60-120s, and then at a high speed for 60-120s. Mix for 150~210s.

[0061] In a specific embodiment of the present invention, the temperature of the mixing is 40-50°C.

[0062] In a specific embodiment of the present invention, the low speed is 50-70 r / min.

[0063] In a specific embodiment of the present invention, the high speed is 200˜400 r / min.

[0064] ...

Embodiment 1~6

[0067] This embodiment provides multiple groups of low-smoke, drip-free, halogen-free flame-retardant polycarbonate compositions and preparation methods thereof, wherein the raw materials of the low-smoke, drip-free, halogen-free flame-retardant polycarbonate compositions of each embodiment are Information is shown in Table 1 and Table 2, and the preparation method includes the following steps:

[0068] (1) Combine anti-drip agent SN3307PF, release agent SP10S, heat stabilizer B900 and polycarbonate with a melt index of 10-12 (PC-MI 10-12) were mixed in a mixer at 45°C at 60 rpm for 90 s, and then at 300 rpm for 180 s. mix.

[0069] (2) Weigh polycarbonate with a melt index of 6 to 8 (PC-MI 6 to 8), polycarbonate with a melt index of 10 to 12 (PC-MI 10 to 12), grafted silicone and The polymer flame retardant of perfluorobutyl and the auxiliary premix obtained in step (1) are mixed and granulated; The die temperature of the screw extruder is 280°C, the temperature in zone 2...

experiment example 1

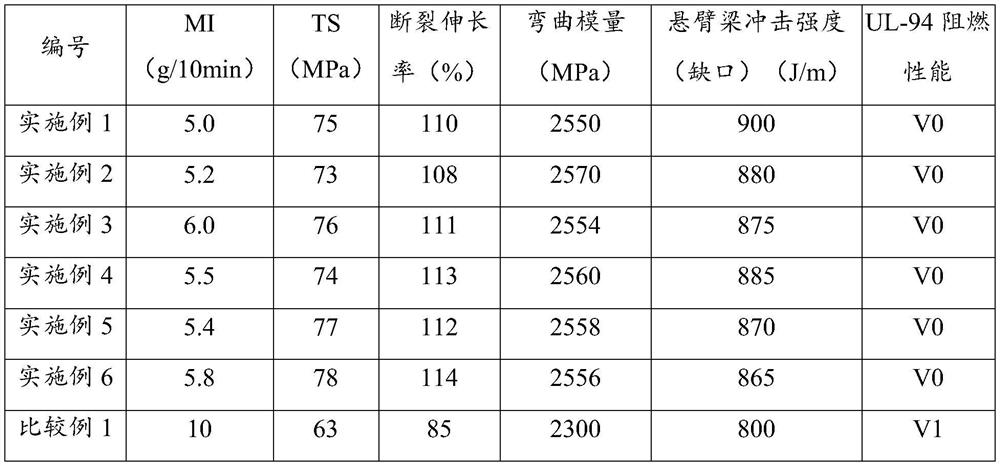

[0081] In order to compare and illustrate the properties of the polycarbonate compositions prepared in different examples and comparative examples, the properties of the polycarbonate compositions prepared in each example and comparative example were tested, and the test results are shown in Table 3.

[0082] Among them, the test condition of melt index MI is 300℃ / 1.2kg, refer to ISO 1133-1;

[0083] The test condition of tensile strength TS is 50mm / min, refer to ISO 527-2;

[0084] The test condition of elongation at break EL is 50mm / min, refer to ISO 527-2;

[0085] The test condition of flexural modulus EF is 2mm / min, refer to ISO 178;

[0086] Izod impact strength (notched), test condition 25°C, refer to ASTM D256.

[0087] Table 3 Test results for different polycarbonate compositions

[0088]

[0089] It can be seen from the above test results that the low-smoke, non-drip, halogen-free and flame-retardant polycarbonate composition of the present invention can improv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com