Tannic acid/eleostearic acid toughened shellac resin anti-corrosion coating and preparation method thereof

A technology of shellac resin and anti-corrosion coating, which is applied in the direction of shellac coating, anti-corrosion coating, coating, etc., can solve the problems of poor anti-corrosion performance, and achieve the effect of high use value, good anti-corrosion and moisture-proof, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 1. Tung oleic acid toughening modification treatment

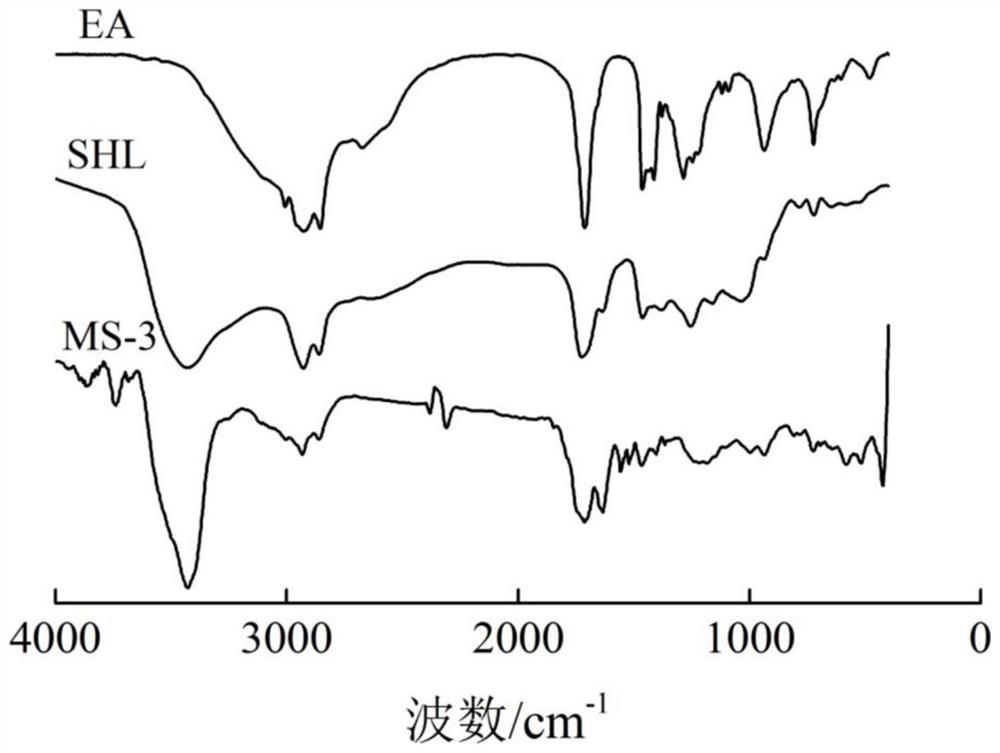

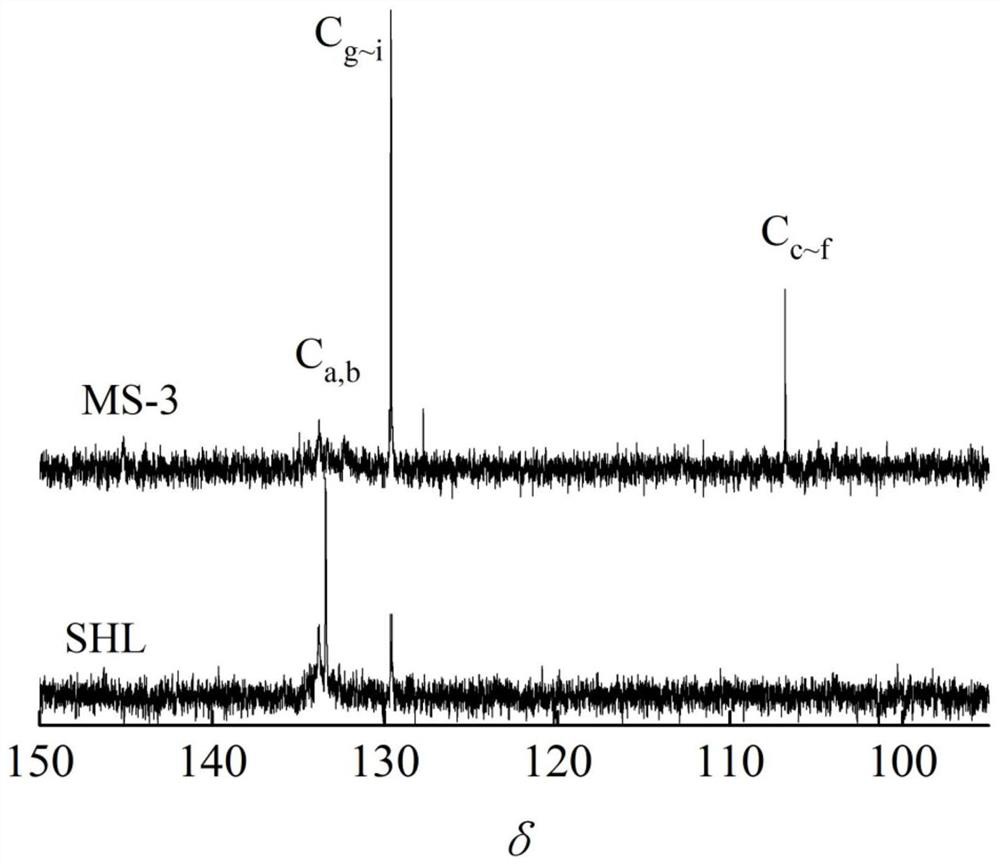

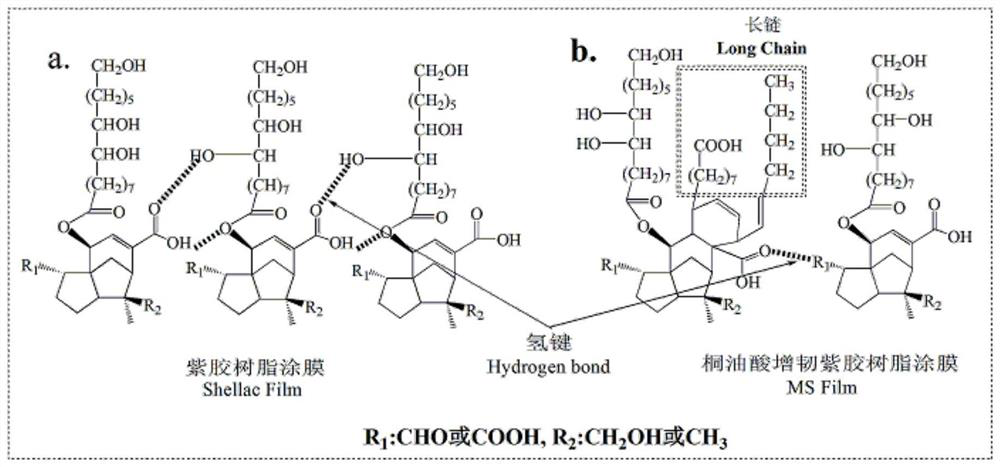

[0057] Diels-Alder addition was performed between the double bond in the shellac resin and the conjugated double bond of eleostearic acid, and the eleostearic acid was introduced into the structure of the shellac resin.

[0058] 1-1. Diels-Alder addition reaction

[0059] Accurately weighed shellac resin 12g and eleuic acid 2g were placed in a clean 250mL single-necked flask, and a diluent DMF (3mL) was added (the diluent is used to reduce the viscosity of the system); then the flask was placed in a metal bath, heated and heated. , carry out a metal bath to completely melt the reactants in the flask, reflux and stir under the condition that the temperature of the metal bath reaction system is kept at 110 ° C (usually 100-130 ° C), and carry out toughening modification treatment, toughening modification treatment process Diels-Alder addition reaction occurs between shellac resin and tauoleic acid, that is, the shell...

Embodiment 1A

[0072] In addition to step 2) in the process of compounding tannic acid, weigh the eleostearic acid toughened shellac resin (MS-1) prepared in step 1) and place it in a clean beaker, and then inject an appropriate amount of 0.3M NH 3 The solution (aqueous ammonia solution) was stirred and dissolved to obtain the tauoleic acid toughened shellac resin-ammonia water system, and the rest were the same as in Example 1, namely, 10 mL of the tauoleic acid toughened shellac resin-ammonia water system was obtained, and the tauoleic acid toughened shellac resin-aqueous ammonia system was obtained. The solid content of the shellac resin-ammonia system is 15wt.% (usually 8-25wt.%), that is, a coating liquid with a solid content of 15wt.% (usually 8-25wt.%) is prepared;

[0073]In the present embodiment, the ammonia solution with a concentration of 0.3M is used to dissolve the shellac resin and the tauoleic acid toughened shellac resin, and the ammonia solution with other concentrations (fo...

Embodiment 2

[0076] 1. Tung oleic acid toughening modification treatment

[0077] Except that the quality of the accurately weighed eleostearic acid is 4g, the mass ratio of shellac resin and eleostearic acid is 3:1; the consumption of diluent DMF is to dilute every 6g of shellac resin with 1mL DMF; the temperature of Diels-Alder addition reaction The temperature is 100° C. and the reaction time is 4h, the rest is the same as that in Example 1, and the eleostearic acid toughened shellac resin (MS-2) is obtained.

[0078] 2. Tannin compound treatment

[0079] Except that the solid content of the eleostearic acid toughened shellac resin-ethanol system is 15wt.%; the ratio of the added mass of tannic acid to the mass of the eleostearic acid toughened shellac resin-ethanol system is 0.5 : 100; except that the stirring reaction time was 30 min, the rest were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Polarization resistance | aaaaa | aaaaa |

| Polarization resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com