Microwave-assisted method for preparing mixed solid acid from fishbone

A microwave-assisted, solid acid technology is applied in the field of green conversion and utilization of biomass and environmental protection, which can solve the problems of large demand for fish bone carbon and limited effect, and achieve high cost performance, small environmental footprint, and simple synthesis process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

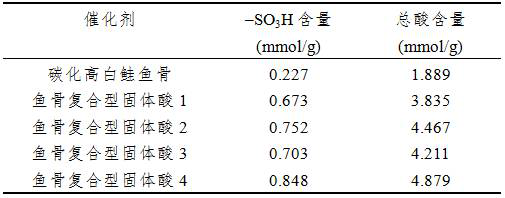

[0055] Example 1. Preparation of high white salmon bone complex solid acid.

[0056] (1) After washing and air-drying, the raw material of high white salmon bone is crushed to a particle size of 1mm-25mm for use. The high white salmon bone comes from the high white salmon processing solid waste provided by Sailimu Lake Fishery Company.

[0057] (2) Take high white salmon bone granules and concentrated sulfuric acid, and soak them for 12 hours according to the ratio of fish bone to concentrated sulfuric acid at a weight ratio of 1:1.

[0058] (3) Take the soaked high white salmon bone pellets, wash them with deionized water three times that of concentrated sulfuric acid, and then dry them in a hot air dryer at 95°C for 18 hours before use.

[0059] (4) Preparation of fishbone composite solid acid crude product: take the dried high white salmon bone particles in step (3), place it in a closed microwave reactor cavity, fill with nitrogen to exhaust air, turn on the microwave gen...

Embodiment 2

[0064] Example 2. Preparation of silver carp and bighead carp bone composite solid acid.

[0065] (1) The raw material of silver carp and bighead carp bone is washed and air-dried, and then pulverized to a particle size of 1mm-25mm for use. Said silver carp and bighead carp bone is from the solid waste of silver carp and bighead processing.

[0066] (2) Take silver carp and bighead carp bone particles and concentrated sulfuric acid, and soak them for 12 hours according to the ratio of fish bone to concentrated sulfuric acid weight of 1:5.

[0067] (3) Take the soaked silver carp and bighead carp bone pellets, wash with deionized water three times that of concentrated sulfuric acid, and then dry in a hot air dryer at 60°C for 24 hours before use.

[0068] (4) Preparation of fish-bone composite solid acid crude product: take the dried silver carp and bighead carp bone particles in step (3), place it in a closed microwave reactor cavity, fill with nitrogen to exhaust air, turn o...

Embodiment 3

[0073] Example 3. Preparation of rainbow trout bone composite solid acid.

[0074] (1) The raw materials of rainbow trout bones are washed and air-dried, and then pulverized to a particle size of 1mm-25mm for use.

[0075] (2) Take rainbow trout bone particles and concentrated sulfuric acid, and soak them for 12 hours according to the weight ratio of fish bone to concentrated sulfuric acid of 1:0.5.

[0076] (3) Take the soaked rainbow trout bone pellets, wash them with deionized water three times that of concentrated sulfuric acid, and then dry them in a hot air dryer at 105°C for 6 hours before use.

[0077] (4) Preparation of fishbone composite solid acid crude product: take the dried rainbow trout bone particles in step (3), place them in a closed microwave reactor cavity, fill with nitrogen to discharge the air, turn on the microwave generator, and set the reaction temperature 750 ℃, microwave output power 500w / kg, reaction time is 20min; after the reaction is completed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com