Composite carrier material supported cobalt-based catalyst and preparation and application thereof

A technology of cobalt-based catalyst and composite carrier, which is applied in the field of catalysis, can solve the problems of reduced reduction degree, poor metal dispersion, and weak interaction force of metal Co, and achieves increased pore volume and pore size, high selectivity, and good catalytic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Preparation of ZIF-9@SiO 2 : Co(NO 3 ) 2 ·6H 2 O (5.82g, 0.02mol) and benzimidazole (6.16g, 0.075mol) were dissolved in 150mL methanol, respectively, and then mixed with 2g SiO 2 Mix quickly and evenly, stir at room temperature for 24 hours, centrifuge the solid at high speed (10000r / min) and wash it with methanol 3 times, and dry at 60°C to obtain ZIF-9@SiO 2 , the structure of the catalyst precursor can be observed by scanning electron microscopy.

[0020] 2. Preparation of Co-CN@SiO 2 : 2g ZIF-9@SiO 2 It was placed in a quartz tube and passed through a tube furnace, and was heated from room temperature to 1000 °C in an Ar atmosphere at a heating rate of 5 °C / min for in situ pyrolysis for 2 h, and the Ar gas space velocity was 1000 h. -1 , get Co-CN@SiO 2 .

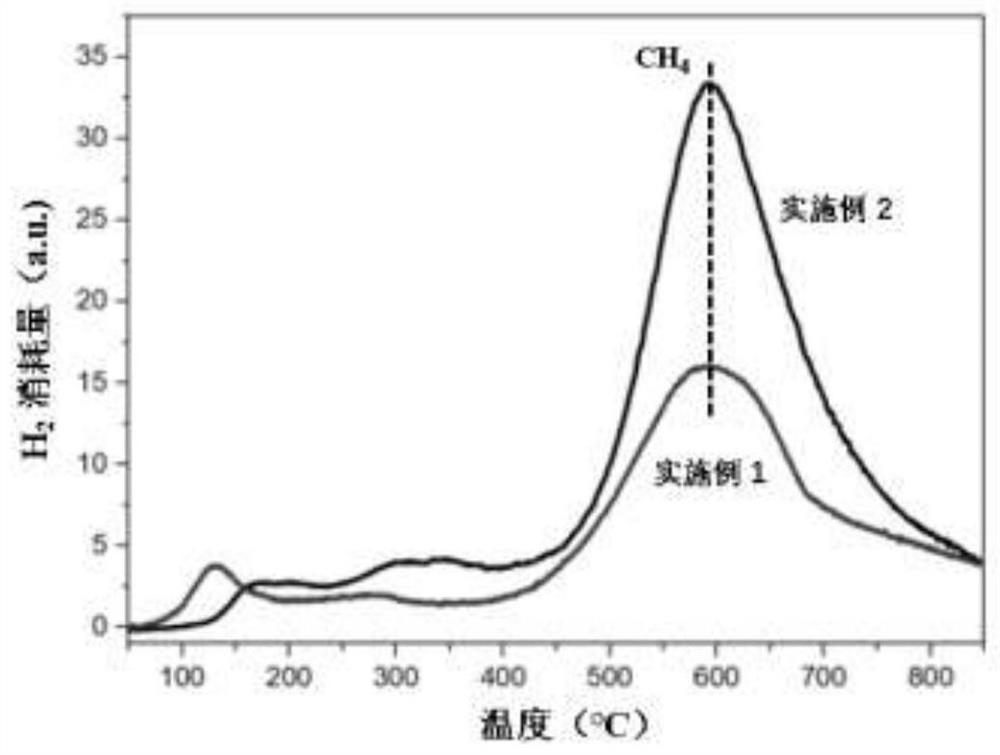

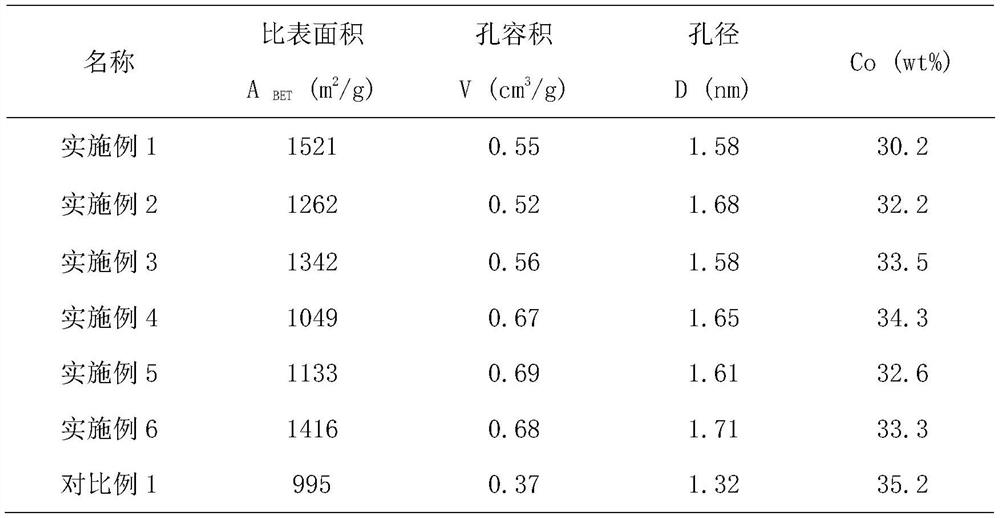

[0021] The specific surface area, pore volume, pore size of the catalyst determined by physical adsorption characterization and the structure and physical properties of the catalyst such as Co content ...

Embodiment 2

[0024] 1. Preparation of ZIF-9@SiO 2 : Co(NO 3 ) 2 ·6H 2 O (5.82g, 0.02mol) and benzimidazole (6.16g, 0.075mol) were dissolved in 150mL methanol, respectively, and then mixed with 2g SiO 2 Mix quickly and evenly, stir at room temperature for 24 hours, centrifuge the solid at high speed (10000r / min) and wash with MeOH 3 times, and dry at 80°C to obtain ZIF-9@SiO 2 , the structure of the catalyst precursor can be observed by scanning electron microscopy.

[0025] 2. Preparation of Co-CN@SiO 2 : 2g ZIF-9@SiO 2 It was placed in a quartz tube and passed through a tube furnace, and was heated from room temperature to 800 °C in an Ar atmosphere at a heating rate of 5 °C / min for in situ pyrolysis for 2 h, and the Ar gas space velocity was 1000 h. -1 , get Co-CN@SiO 2 .

[0026] The specific surface area, pore volume, pore size of the catalyst determined by physical adsorption characterization and the structure and physical properties of the catalyst such as Co content detected...

Embodiment 3

[0029] 1. Preparation of ZIF-9@Al 2 O 3 : Co(NO 3 ) 2 ·6H 2 O (5.82g, 0.02mol) and benzimidazole (6.16g, 0.075mol) were dissolved in 150mL methanol, respectively, and then mixed with 2g SiO 2Mix quickly and evenly, stir at room temperature for 24 hours, centrifuge the solid at high speed (10000r / min) and wash it with MeOH 3 times, and dry at 60°C to obtain ZIF-9@Al 2 O 3 , the structure of the catalyst precursor can be observed by scanning electron microscopy.

[0030] 2. Preparation of Co-CN@Al 2 O 3 : 2g ZIF-9@Al 2 O 3 It was placed in a quartz tube and passed through a tube furnace, and was heated from room temperature to 1000 °C in an Ar atmosphere at a heating rate of 5 °C / min for in situ pyrolysis for 2 h, and the Ar gas space velocity was 1000 h. -1 , get Co-CN@Al 2 O 3 .

[0031] The specific surface area, pore volume, pore size of the catalyst determined by physical adsorption characterization and the structure and physical properties of the catalyst such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com