C6-C9 alkane aromatization catalyst as well as preparation method and application thereof

A C6-C9, catalyst technology, applied in physical/chemical process catalysts, isomerization hydrocarbon production, molecular sieve catalysts, etc., can solve problems such as short service life, low aromatics selectivity, and alkane conversion rate below 60%

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides the preparation method of the C6-C9 alkane aromatization catalyst described in the above scheme, comprising the following steps:

[0047] Carrying out the second metal ion exchange and the first calcination of the hierarchically porous Kβ molecular sieve in turn to obtain M / Kβ molecular sieve, where M is one or more of In, W, Sn and Sb;

[0048] The M / Kβ molecular sieve is impregnated in a Pt metal precursor solution and then calcined for a second time to obtain a C6-C9 alkane aromatization catalyst.

[0049] In the present invention, the preparation methods of the hierarchical porous Kβ molecular sieve include two methods, denoted as method 1 and method 2, method 1 is an organic template method, and method 2 is an alkali-dissolving method, which will be described separately below.

[0050] In the present invention, described method one preferably comprises the following steps:

[0051] The hierarchical porous beta molecular sieve is...

Embodiment 1

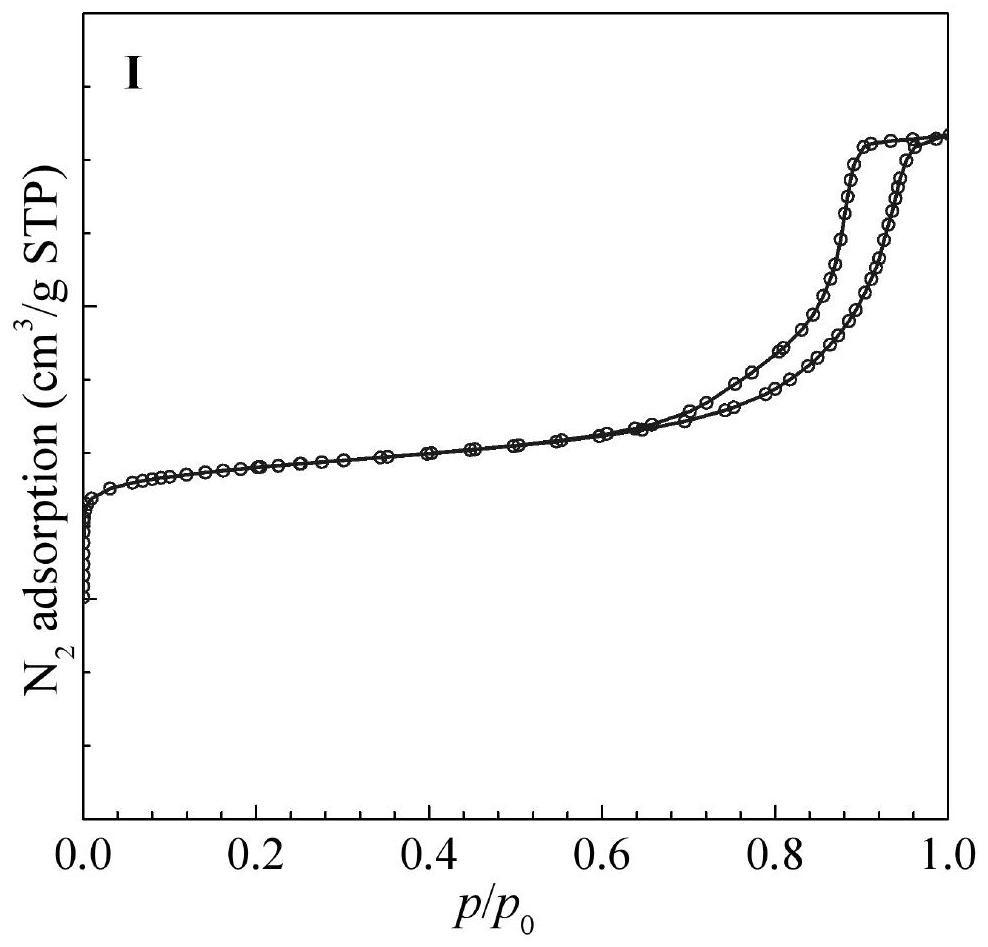

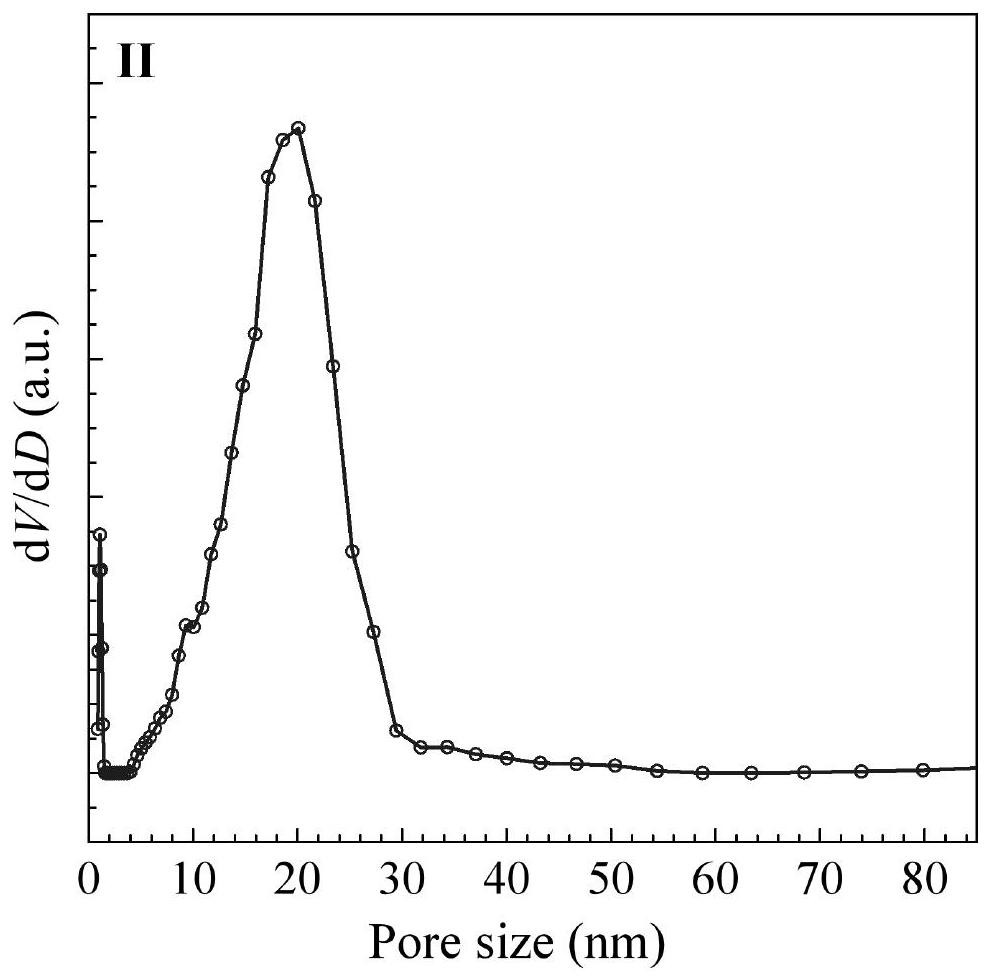

[0079] Preparation of Hierarchical Porous β Molecular Sieve (Na Type) by Organosilylation Reagent Method: Dissolve 0.64g NaOH in 73.64g TEAOH aqueous solution (content is 25%); then add 35.74g SiO slowly with stirring at room temperature 2 sol, and the resulting mixture was stirred for an additional 10 min. 3.33gAl 2 (SO 4 ) 3 ·18H 2 O was dissolved in 20 g of water to form a solution, and the resulting aluminum sulfate solution was then added to the previously obtained sol. After that, the resulting mixture was heated to 80°C, stirred to a gel state, and then transferred to a Teflon cup, which was placed in a Teflon-lined autoclave, and 5.0 g of water was added outside the cup to The steam required for hydrothermal synthesis is generated. Under static conditions, the autoclave was sealed in a preheated air circulation oven and heated at 140°C for 6 h for pre-crystallization. After heating, the autoclave was taken out of the oven and quenched with cooling tap water to At...

Embodiment 2

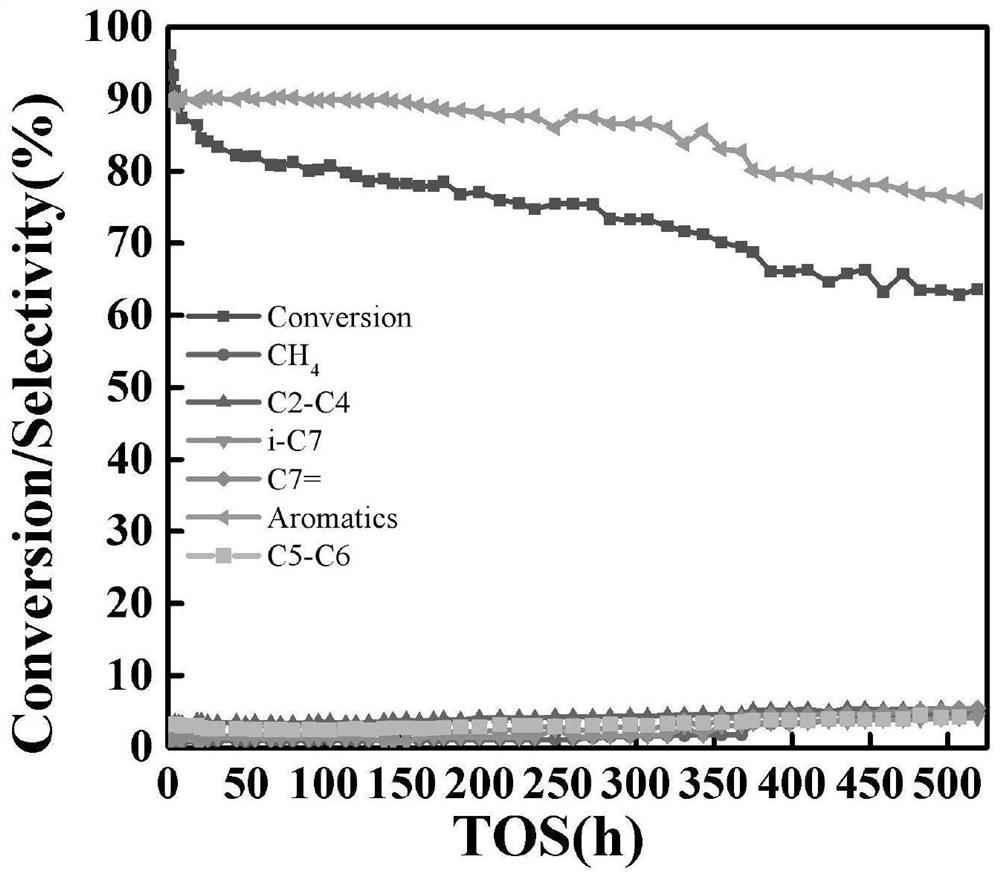

[0088] (1) 3g of the multi-stage porous Hβ molecular sieves prepared in Example 1 were added to 210mL of 1.2mol / L KNO 3 The solution was maintained at 80 °C for 2 h, then washed with deionized water and dried. After exchanging twice according to the above process, the exchanged product was dried, and then calcined at 550°C for 6 hours in an air atmosphere in a muffle furnace to obtain a multi-level porous Kβ molecular sieve;

[0089] (2) 3 g of the hierarchically porous Kβ molecular sieve prepared in step (1) was added to 200 mL of an indium nitrate solution with a concentration of 0.002 mol / L, maintained at 80° C. for 12 hours, and then washed with deionized water and dried. After exchanging once according to the above process, the exchanged product was dried, and then calcined at 500°C for 5h in an air atmosphere in a muffle furnace to obtain In / Kβ molecular sieves;

[0090] (3) using an equal volume impregnation method to load platinum metal with a mass fraction of 1%, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Mesopore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com