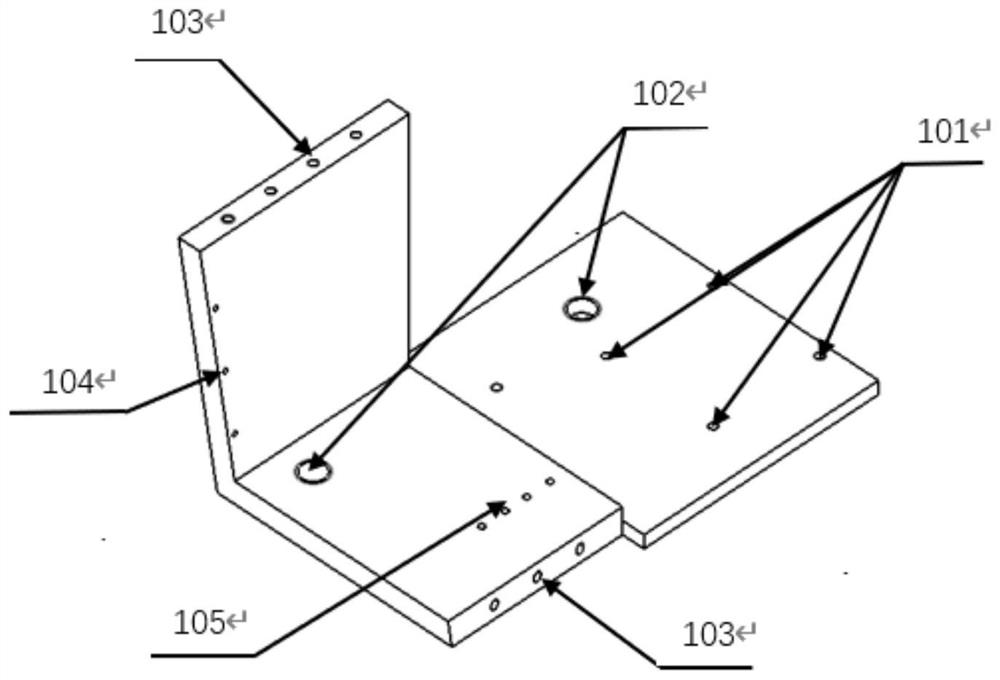

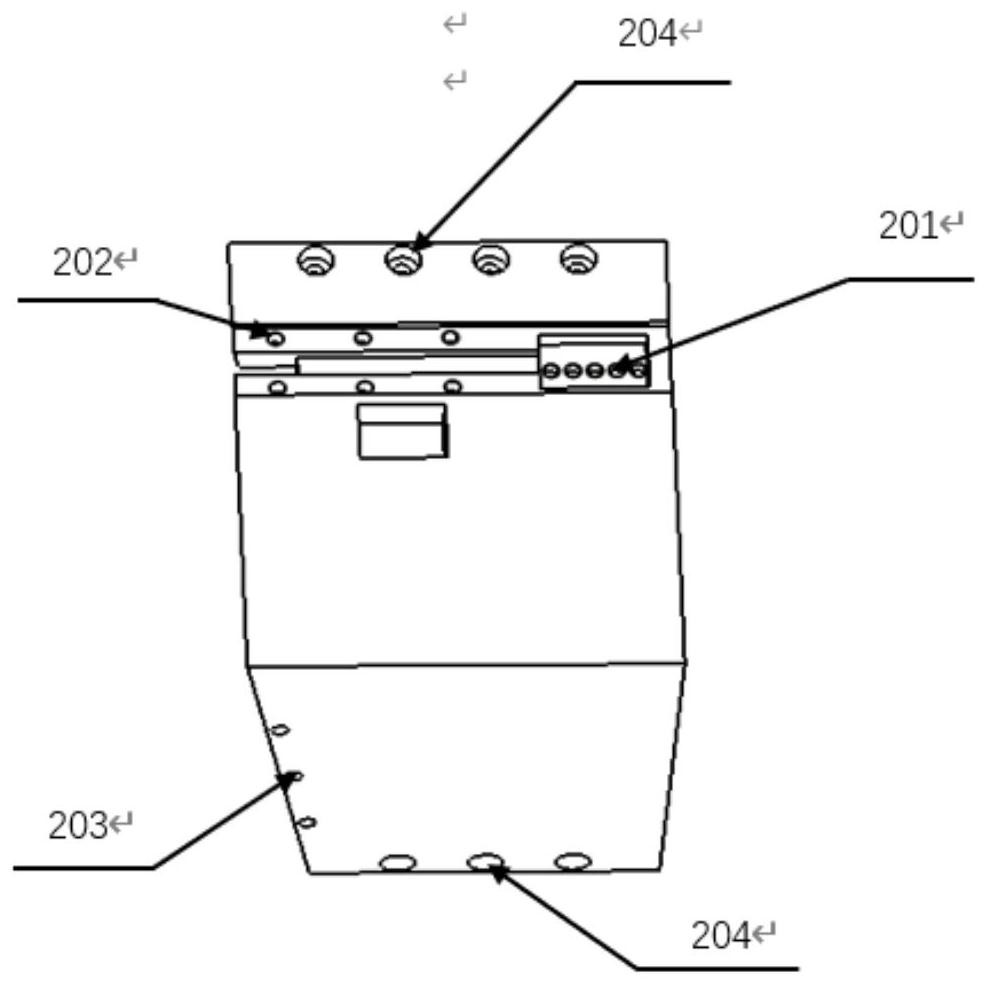

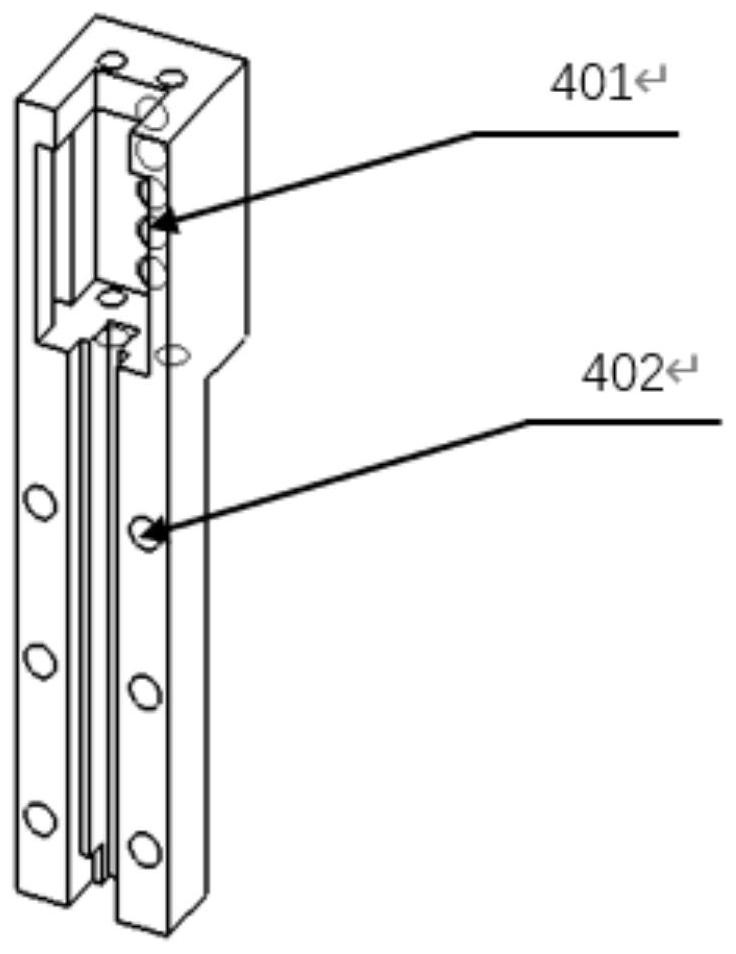

Integrated laser in-situ auxiliary turning device

An integrated, auxiliary vehicle technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of inflexible adjustment of laser incident angle, insufficient tool rigidity, inconvenience, etc., to improve energy utilization, improve Improved surface quality and machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Nowadays, difficult-to-machine materials (hard and brittle materials, superalloys, composite materials, etc.) are widely used in aerospace, aerospace, military, and automobile manufacturing. Use as a component requires a very high surface quality. However, when machining difficult-to-machine materials, there will be large cutting forces, rapid tool wear, and low surface quality. Simple traditional manufacturing and processing cannot meet the needs of current materials in various fields. Therefore, the combination of laser-assisted turning, laser-assisted milling, laser-assisted polishing, and other laser-assisted and traditional processing methods is introduced. Through laser-assisted heating of the workpiece, the purpose of material softening is achieved, and the processing domain characteristics of the workpiece are locally changed, so that difficult-to-machine materials can be processed in the ductile domain, which can reduce cutting force, improve surface quality i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com