Room-temperature vulcanized silicone rubber graphene bionic antifouling composite material with bubble adsorption function

A room temperature vulcanization, composite material technology, applied in the field of chemical biology, can solve the problems of marine biological pollution, poor durability of hydrophilic polymers, etc., and achieve the effects of enhanced antifouling performance, low surface energy, and easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 (production of template)

[0036] 1) Taking Sophora japonica and succulent soft coral as biological models, the template diagrams of four antennae arrays were drawn by CAD.

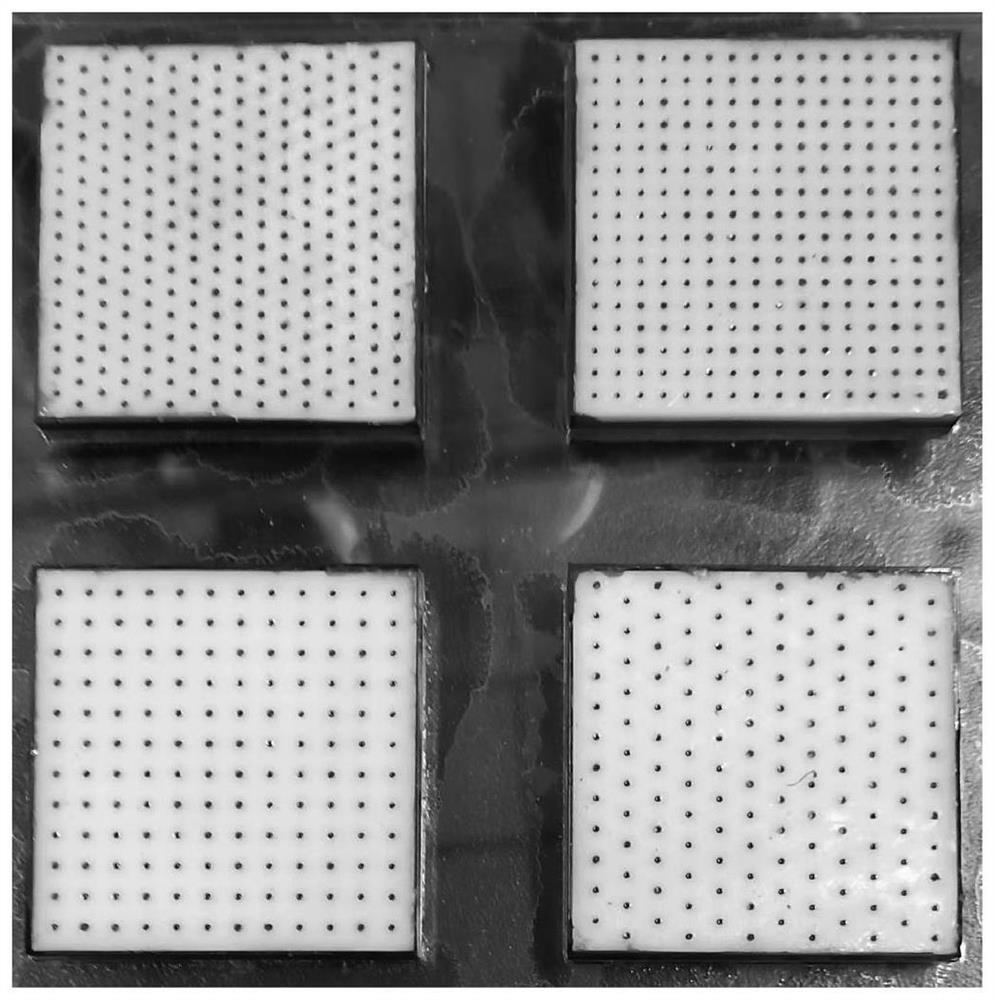

[0037] 2) Using 3D printing technology to print out the template (such as figure 1 ).

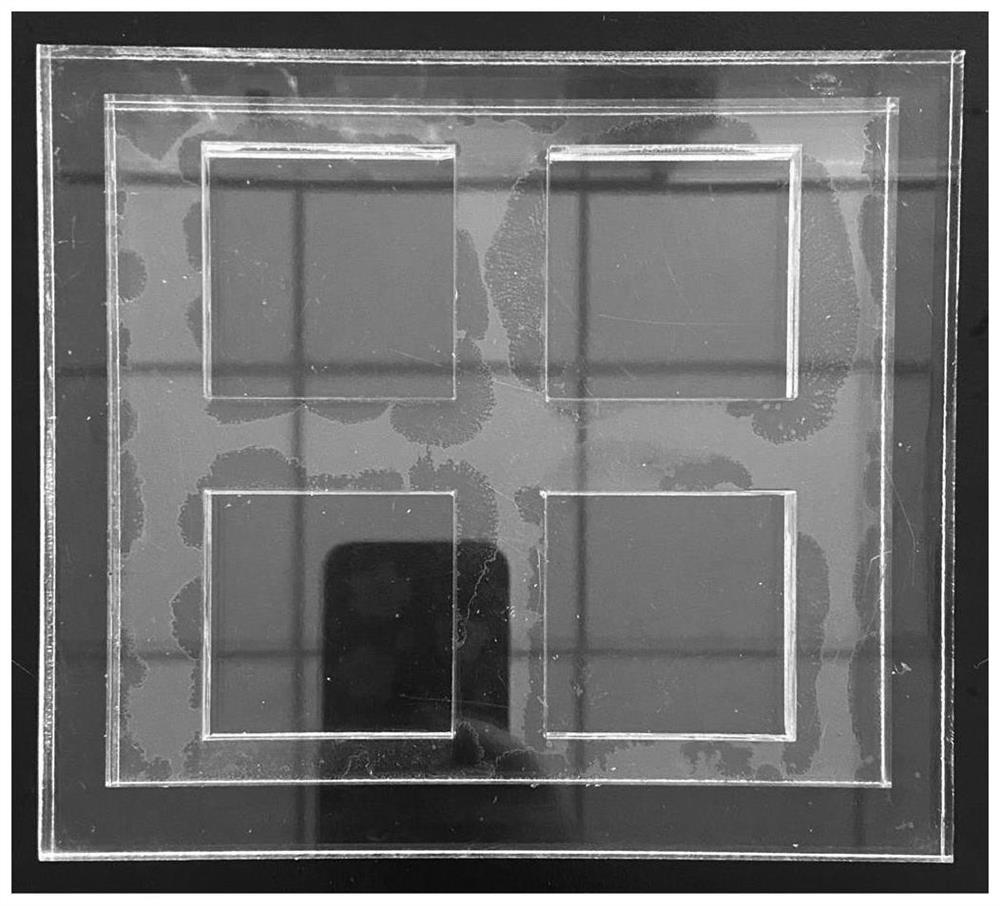

[0038] 3) Customize the acrylic groove according to the size of the template (such as figure 2 ) and a cover plate, so that the template can be placed in the tank and used in the subsequent preparation of antifouling materials.

Embodiment 2

[0039] Example 2 (SR)

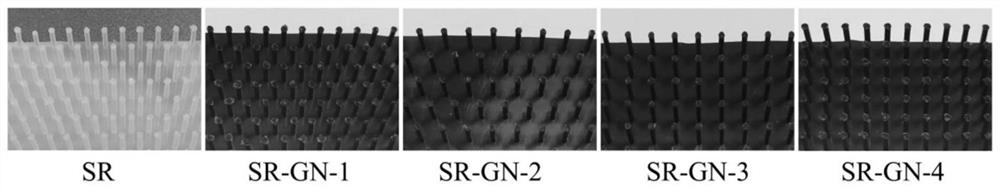

[0040] Weigh 22.97g of room temperature vulcanized silicone rubber and 0.30g of curing agent, stir evenly with a mechanical stirrer at 2000 rpm, and place it in a vacuum box to eliminate air bubbles. After the mixture is free of air bubbles, take it out and pour it into an acrylic tank equipped with a template. After standing for a while, cover it with an acrylic cover, press a heavy object to solidify it for 24 hours, and take it out to obtain the following result: image 3 Antifouling material shown in SR.

Embodiment 3

[0041] Example 3 (SR-GN1 to SR-GN4)

[0042] Weigh 22.86g of room temperature vulcanized silicone rubber, 0.0823g of graphene powder and 0.30g of curing agent, stir evenly with a mechanical stirrer at 2000 rpm, and place them in a vacuum box to eliminate air bubbles. After the mixture is free of air bubbles, take it out and pour it into the acrylic tank equipped with the template. After standing for a while, cover it with an acrylic cover, press a heavy object to cure it for 24 hours and take it out. prepared in turn as image 3 The four antifouling materials shown in SR-GN1 to SR-GN4.

[0043] SR-GN1 is a staggered and densely arranged antenna-like structure, with an antenna-like spacing of 3 mm; SR-GN2 is a staggered and sparsely arranged antenna-like structure with a 4 mm-like antenna-like spacing; SR-GN3 is a parallel and sparsely arranged antenna-like structure, Antenna-like spacing is 4mm; SR-GN4 is a parallel and densely arranged antenna-like structure, and the antenn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com