Benzoxazine-terminated imide, preparation method thereof and polybenzoxazine-terminated imide film

A technology of end-type imide and benzoxazine is applied in the field of polybenzoxazine-terminated imide film, which can solve the problems of low thermal decomposition temperature, inability to meet the requirements of flame retardancy, and stress generation. , to achieve the effect of broad application prospects, meltable and soluble processing, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

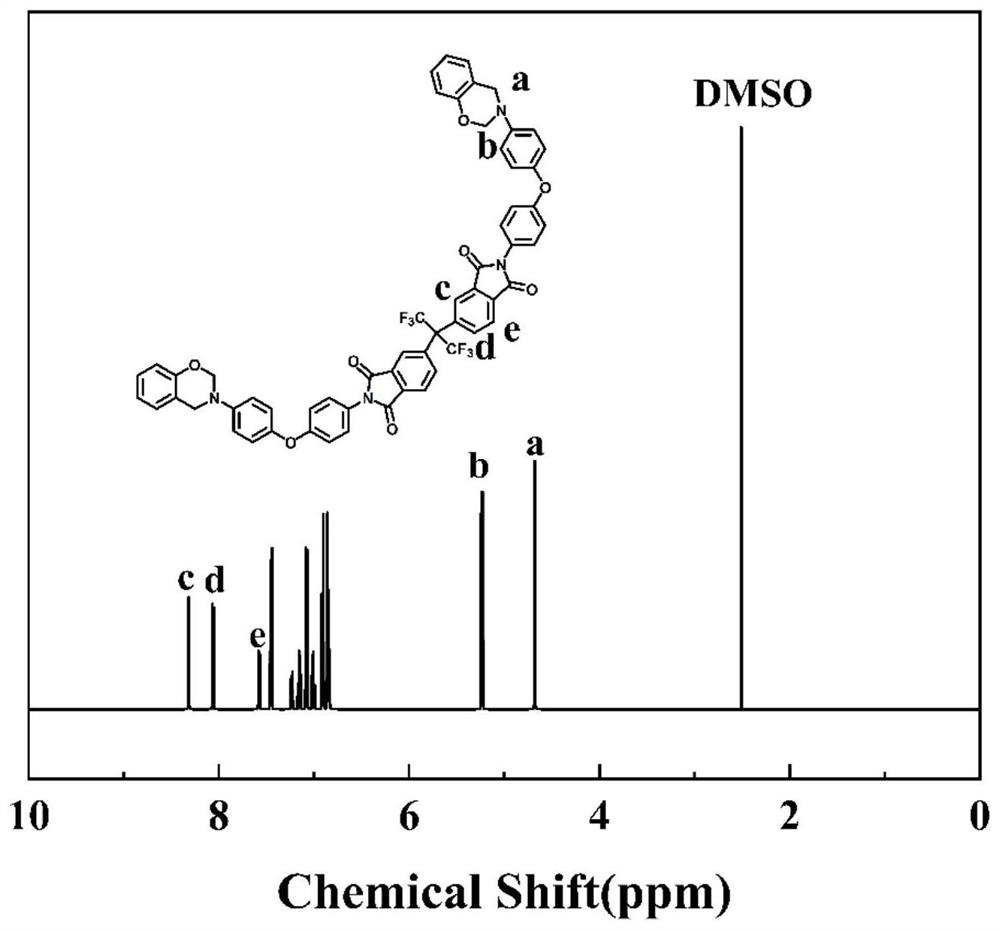

Embodiment 1

[0046] This example relates to the preparation of small molecule benzoxazine-terminated imides using 4,4'-diaminodiphenyl ether, 4,4'-(hexafluoroisopropene)diphthalic anhydride, phenol and paraformaldehyde and its thermosetting film.

[0047] (1) Pass nitrogen into the reactor equipped with mechanical stirring, nitrogen inlet and outlet and thermometer, mix 15mmol (3.003g) 4,4'-diaminodiphenyl ether and 10mmol (4.442g) 4,4'-( Hexafluoroisopropene) diphthalic anhydride was dissolved in 30 ml of N,N-dimethylformamide (DMF) in a ratio of 1.5:1, and reacted at 15° C. for 3 hours. The reaction product was precipitated in water, and vacuum-dried at 80°C for 12 h to obtain powder.

[0048] (2) put the powder obtained above into a tube furnace, feed nitrogen into the tube furnace, heat up to 350 ° C and solidify into a diamine-terminated imide, because the melting temperature is lower, the diamine-terminated amide The imine is melted and then cooled to form a film, which needs to be...

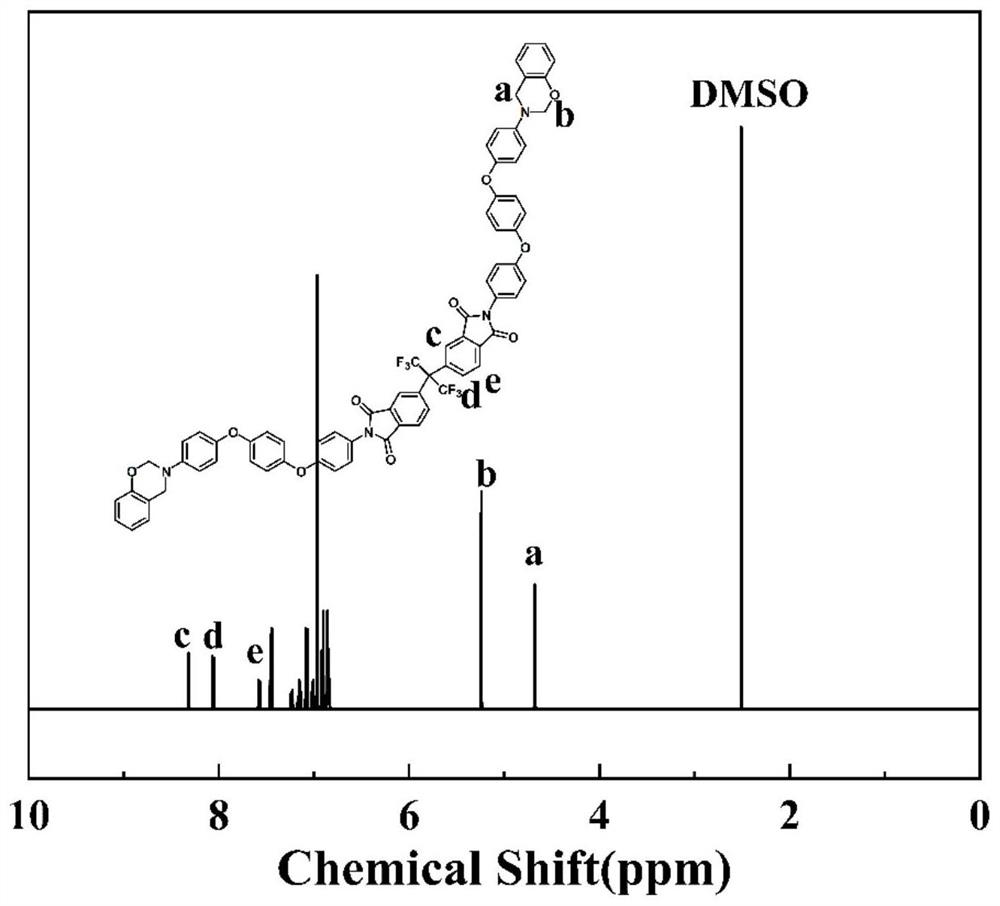

Embodiment 2

[0056] This example involves the use of 1,4-bis(4-aminophenoxy)benzene, 4,4'-(hexafluoroisopropene)diphthalic anhydride, phenol, and paraformaldehyde to prepare small molecule benzoxazine endcaps type imide and its thermosetting film.

[0057] (1) Pass nitrogen into the reactor equipped with mechanical stirring, nitrogen inlet and outlet and thermometer, and mix 15mmol (4.385g) 1,4-bis(4-aminophenoxy)benzene and 10mmol (4.442g) 4 ,4'-(hexafluoroisopropene)diphthalic anhydride was dissolved in 30 ml of N,N-dimethylformamide (DMF) in a material ratio of 1.5:1, and reacted at 15°C for 3 hours. The reaction product was precipitated in water, and vacuum-dried at 80°C for 12 h to obtain powder.

[0058] (2) put the powder obtained above into a tube furnace, feed nitrogen into the tube furnace, heat up to 350 ° C and solidify into a small molecular amine group terminated imide, because the melting temperature is low, the small molecular amine The base-terminated imide is melted and...

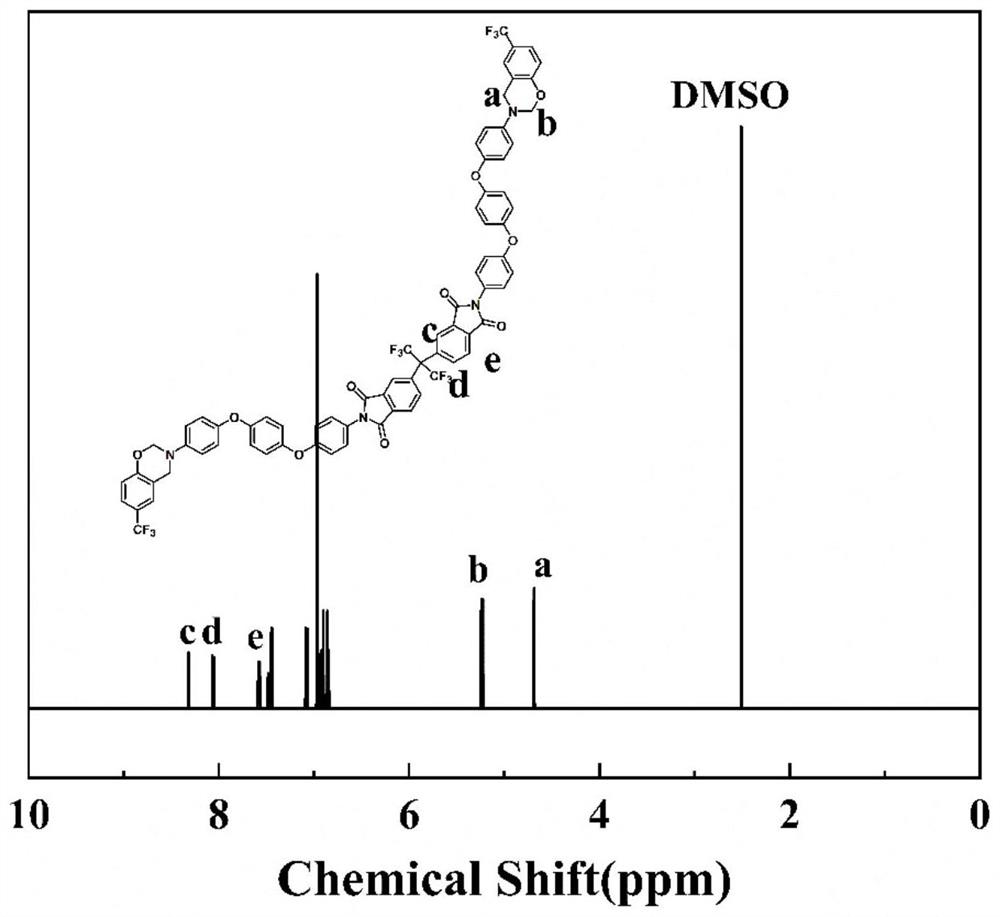

Embodiment 3

[0066] This example involves the use of 1,4-bis(4-aminophenoxy)benzene, 4,4'-(hexafluoroisopropene)diphthalic anhydride, p-trifluorophenol, and paraformaldehyde to prepare small molecule benzoxanes Azine-terminated imides and their thermally cured films.

[0067] (1) feed nitrogen into the reactor equipped with mechanical stirring, nitrogen inlet and outlet and thermometer, 15mmol (4.385g) 1,4-bis (4-aminophenoxy) benzene and 10mmol (4.442g) 4, 4'-(Hexafluoroisopropene)diphthalic anhydride was dissolved in 30 ml of N,N-dimethylformamide (DMF) in a substance ratio of 1.5:1, and reacted at 15° C. for 3 hours. The reaction product was precipitated in water, and vacuum-dried at 80°C for 12 h to obtain powder.

[0068] (2) put the powder obtained above into a tube furnace, feed nitrogen into the tube furnace, heat up to 350 ° C and solidify into a small molecular amine group terminated imide, because the melting temperature is low, the small molecular amine The base-terminated im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com