High-strength antistatic 3D sheet and preparation method thereof

An anti-static and high-strength technology, applied in the field of resin sheet processing, can solve the problems of combustion and explosion, breakdown of mobile phone components, loss of mobile phone life and other problems, and achieve the effect of improving service life, improving mechanical strength and improving heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

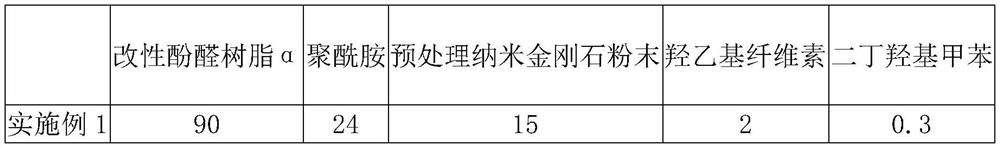

Embodiment 1

[0053] A high-strength antistatic 3D sheet, the preparation method comprising the following steps;

[0054] (1) Preparation of prepreg: S1. Mix nano-diamond powder and toluene solvent, and ultrasonically disperse for 7 minutes to obtain nano-diamond dispersion; under nitrogen atmosphere, drop nano-diamond dispersion into red aluminum solution, under inert gas protection The temperature was raised to 115 °C, reacted for 4 h, washed with distilled water for three times, dehydrated with a vacuum degree of -0.099MpaMpa, and dried to constant weight to obtain pretreated nano-diamond powder;

[0055] S2 Dissolve modified phenolic resin α in dimethylformamide, cool down to -20°C, add cross-linking agent hydroxyethyl cellulose, antioxidant dibutyl hydroxytoluene, pretreated nano-diamond powder, stir for 8 minutes, and then Add polyamide curing agent, stir for 30min, stirring speed is 800r / min to obtain glue;

[0056] S3. Arrange the glass fibers in the mixed solution of PEDOT and sod...

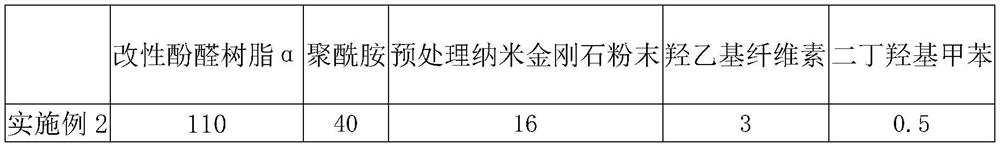

Embodiment 2

[0065] A high-strength antistatic 3D sheet, the preparation method comprising the following steps;

[0066] (1) Preparation of prepreg; S1. Mix nano-diamond powder and toluene solvent, ultrasonically disperse for 9 min, to obtain nano-diamond dispersion; under nitrogen atmosphere, drop nano-diamond dispersion into red aluminum solution, under inert gas protection The temperature was raised to 127°C, reacted for 5h, washed three times with distilled water, dehydrated with a vacuum degree of -0.097Mpa, and dried to constant weight to obtain pretreated nano-diamond powder;

[0067] S2. Dissolve the modified phenolic resin α in dimethylformamide, cool down to -20°C, add crosslinking agent hydroxyethyl cellulose, antioxidant dibutyl hydroxytoluene, pretreated nano-diamond powder, stir for 9 minutes, Then add polyamide curing agent, stir for 32min, stirring speed is 900r / min to obtain glue;

[0068] S3. Arrange the glass fibers in the mixed solution of PEDOT and sodium polystyrene ...

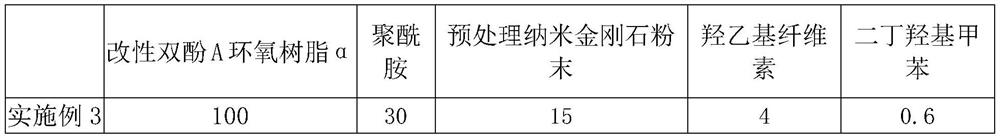

Embodiment 3

[0077] A high-strength antistatic 3D sheet, the preparation method comprising the following steps;

[0078] (1) Preparation of prepreg: S1. Mix nano-diamond powder and toluene solvent, and ultrasonically disperse for 7 minutes to obtain nano-diamond dispersion; under nitrogen atmosphere, drop nano-diamond dispersion into red aluminum solution, under inert gas protection The temperature was raised to 115 °C, reacted for 4 h, washed with distilled water for three times, dehydrated with a vacuum degree of -0.099MpaMpa, and dried to constant weight to obtain pretreated nano-diamond powder;

[0079] S2 Dissolve modified bisphenol A resin α in dimethylformamide, cool down to -20°C, add cross-linking agent hydroxyethyl cellulose, antioxidant dibutyl hydroxytoluene, pretreated nano-diamond powder, and stir for 8 minutes , then add the polyamide curing agent, stir for 30min, and the stirring speed is 800r / min to obtain the glue;

[0080]S3. Arrange the glass fibers in the mixed soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com