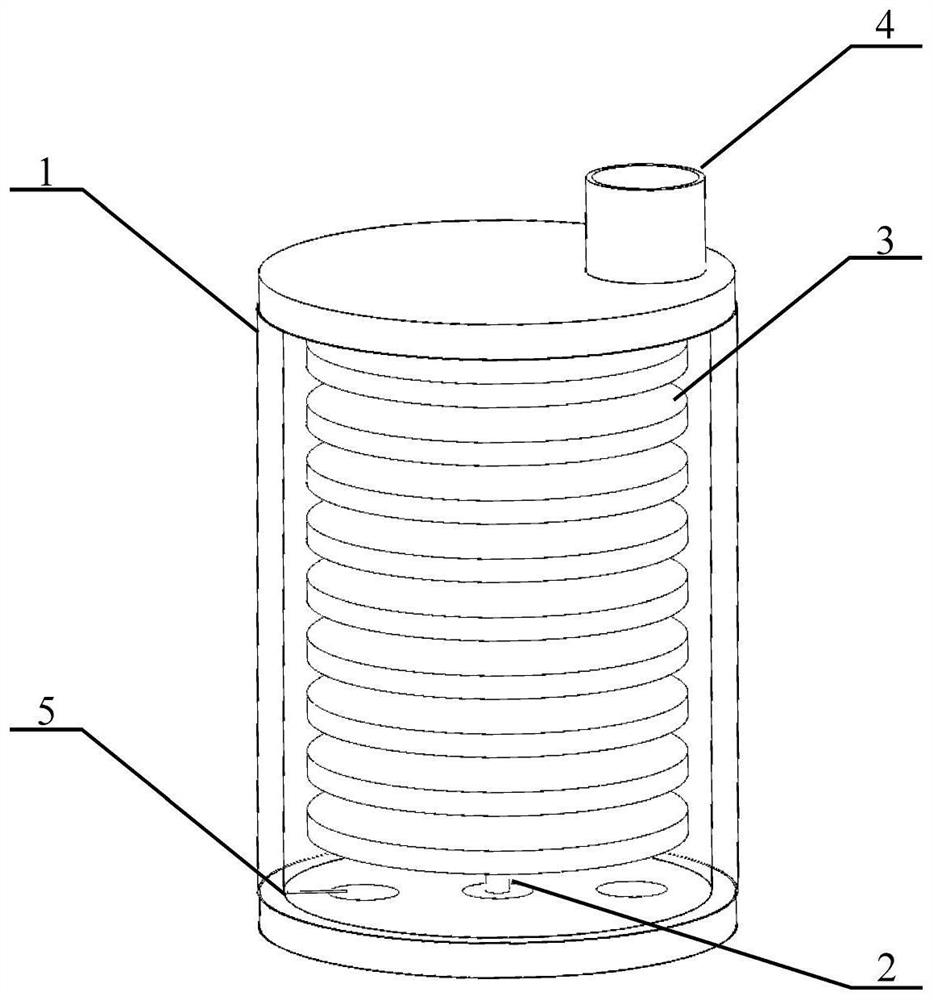

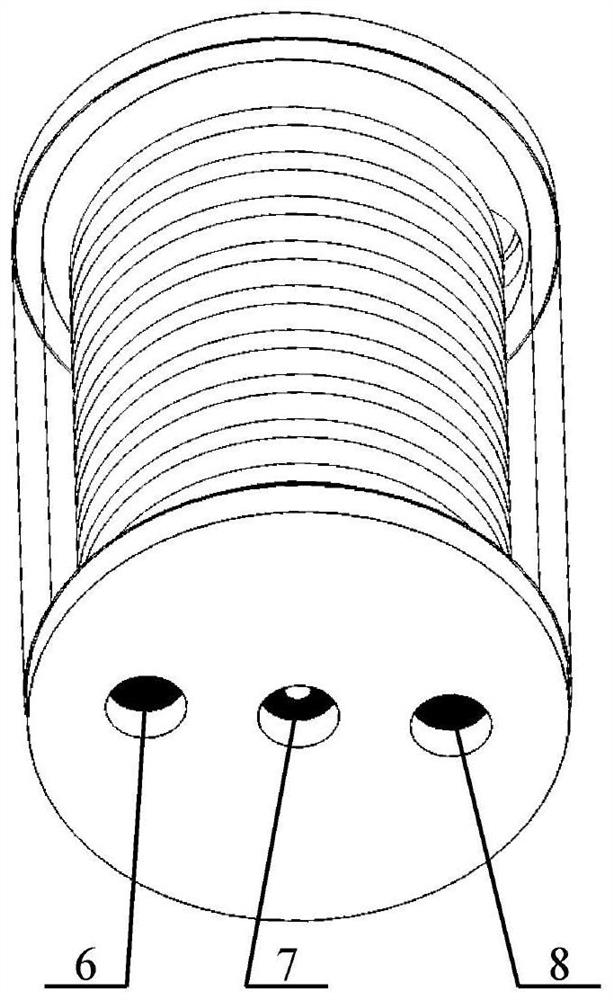

Preparation method of hydrophobic oleophylic polyurethane sponge and oil-water separation device

A technology of oil-water separation device and polyurethane sponge, which is applied in the direction of grease/oily substance/floating matter removal device, separation method, liquid separation, etc. It can solve the problems of oil-absorbing felt that cannot be reused, high consumables, and low efficiency, and achieve excellent reliability Reusability, accelerated outflow, and anti-sticking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

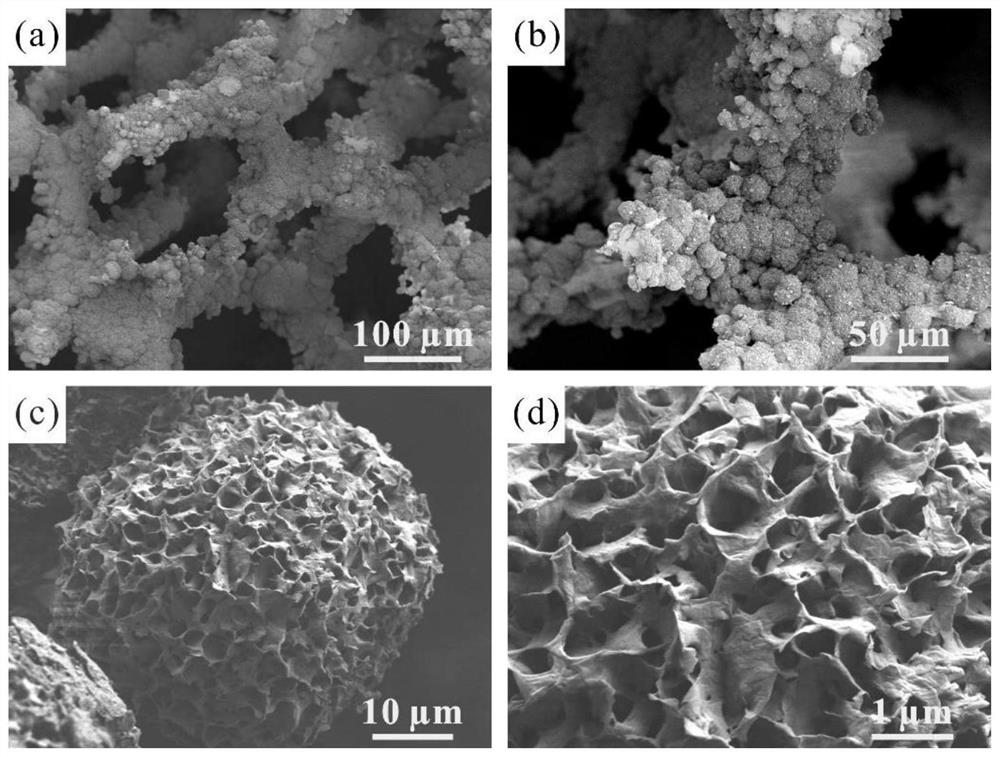

[0042] A preparation method of hydrophobic and lipophilic polyurethane sponge, comprising the following steps:

[0043] The polyurethane sponge was sequentially added to acetone, ethanol and deionized solution for ultrasonic cleaning, and the ultrasonic cleaning time was 10 minutes; the cleaned polyurethane sponge was placed in an oven at 40 ° C for heating and drying, and the drying time was 20 minutes;

[0044] Mix 2 g of epoxy resin and curing agent in a ratio of 1:3 to obtain a brown epoxy resin solution; add 4 g of zinc oxide powder and 15 mL of acetone to the brown epoxy resin solution and perform magnetic stirring at room temperature for 30 min to obtain Mixed solution of epoxy resin and zinc oxide polyurethane;

[0045] The dried polyurethane sponge was immersed in the mixed solution of epoxy resin and zinc oxide polyurethane, and after fully absorbed, centrifuged in a centrifuge at 1000 rpm for 3 min, and the dip coating and centrifugation process was repeated twice; ...

Embodiment 2

[0049] Put the polyurethane sponge into acetone, ethanol and deionized solution for ultrasonic cleaning in sequence, each for 10 minutes; put the cleaned polyurethane sponge into a 40°C oven for heating and drying, and the drying time is 20 minutes.

[0050] Mix 4 g of epoxy resin and curing agent in a mass ratio of 1:3 to obtain a brown epoxy resin solution; add 6 g of zinc oxide powder and 15 mL of acetone to the brown epoxy resin solution, and perform magnetic stirring at room temperature for 30 min. A mixed solution of epoxy resin and zinc oxide is obtained;

[0051] Put the dried polyurethane sponge into the mixed solution of epoxy resin and zinc oxide, and after fully absorbing, centrifuge for 3 minutes in a centrifuge at 1000 rpm, and repeat the dip coating and centrifugation process 5 times; The epoxy resin and zinc oxide polyurethane sponge were obtained by drying in an oven at 60 °C for 8 h.

[0052] The dried epoxy resin and zinc oxide polyurethane sponge were imme...

Embodiment 3

[0055] Put the polyurethane sponge into acetone, ethanol and deionized solution for ultrasonic cleaning in sequence, each for 10 minutes; put the cleaned polyurethane sponge into a 40°C oven for heating and drying, and the drying time is 20 minutes.

[0056] Mix 6 g of epoxy resin and curing agent in a ratio of 1:3 to obtain a brown epoxy resin solution; add 9 g of zinc oxide powder and 15 mL of acetone to the brown epoxy resin solution and perform magnetic stirring at room temperature for 30 min to obtain a ring. Mixed solution of oxygen resin and zinc oxide.

[0057] The dried polyurethane sponge was immersed in a mixed solution of epoxy resin and zinc oxide, and after fully absorbed, centrifuged in a centrifuge at 1000 rpm for 3 min and repeated the dip coating and centrifugation process 10 times; The epoxy resin and zinc oxide polyurethane sponge were obtained by drying in an oven at 60 °C for 8 h.

[0058] The dried epoxy resin and zinc oxide polyurethane sponge were imm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com