High-transparency antibacterial coating as well as preparation method and application thereof

An antibacterial coating and transparency technology, applied in the field of functional coatings, can solve the problems of complex preparation methods of antibacterial agents, low transparency of the protective film layer, easy discoloration of the coating and not durable, etc., and achieves a short preparation period and a small average size. , the effect of little impact on mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

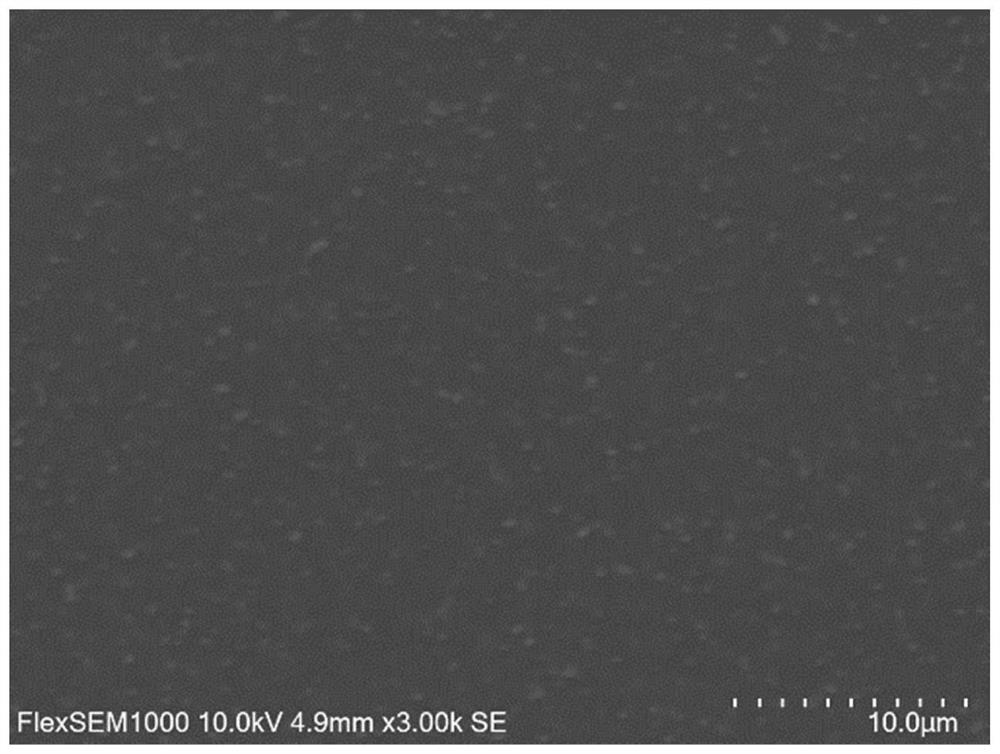

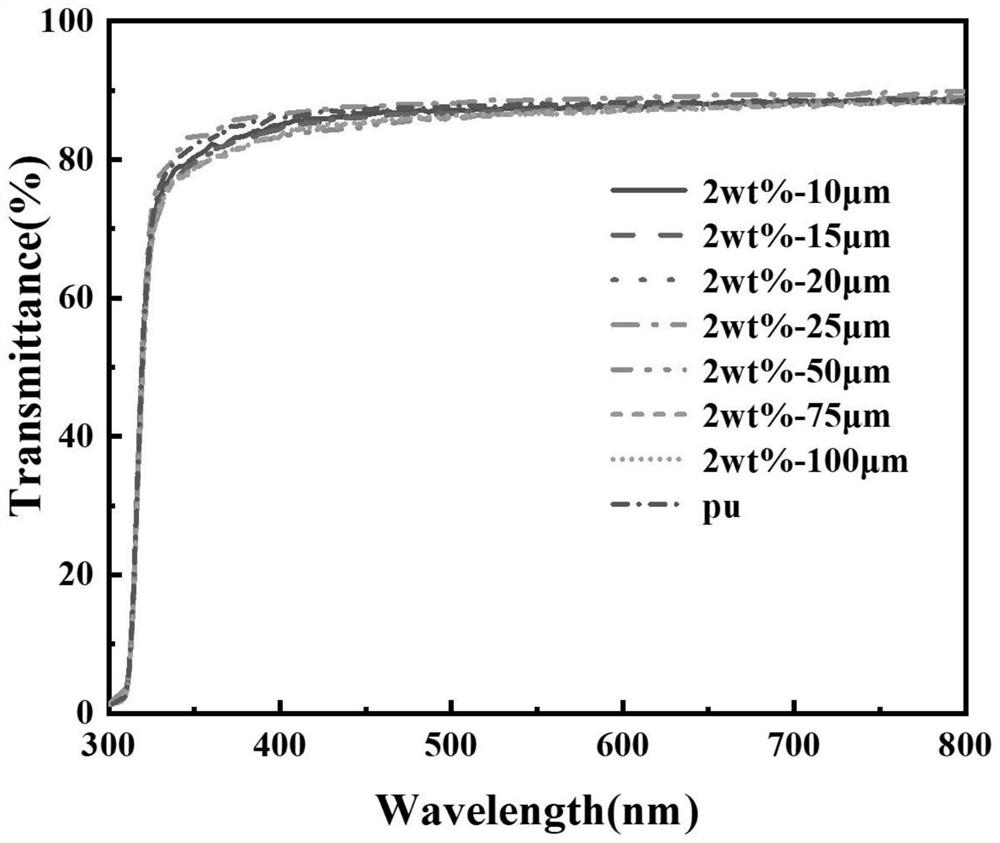

[0038] In this embodiment, a high-transparency antibacterial coating is formed by coating the antibacterial coating material on the surface of the substrate, and curing it on the substrate to form the antibacterial coating; the antibacterial coating material includes a resin matrix and an inorganic Nano antibacterial agent, the inorganic nano antibacterial agent is uniformly dispersed in a resin matrix to form a film on the surface of the base material, and the inorganic antibacterial agent is sodium zirconium phosphate loaded with silver ions.

[0039] A preparation method of the high-transparency antibacterial coating, comprising the following steps:

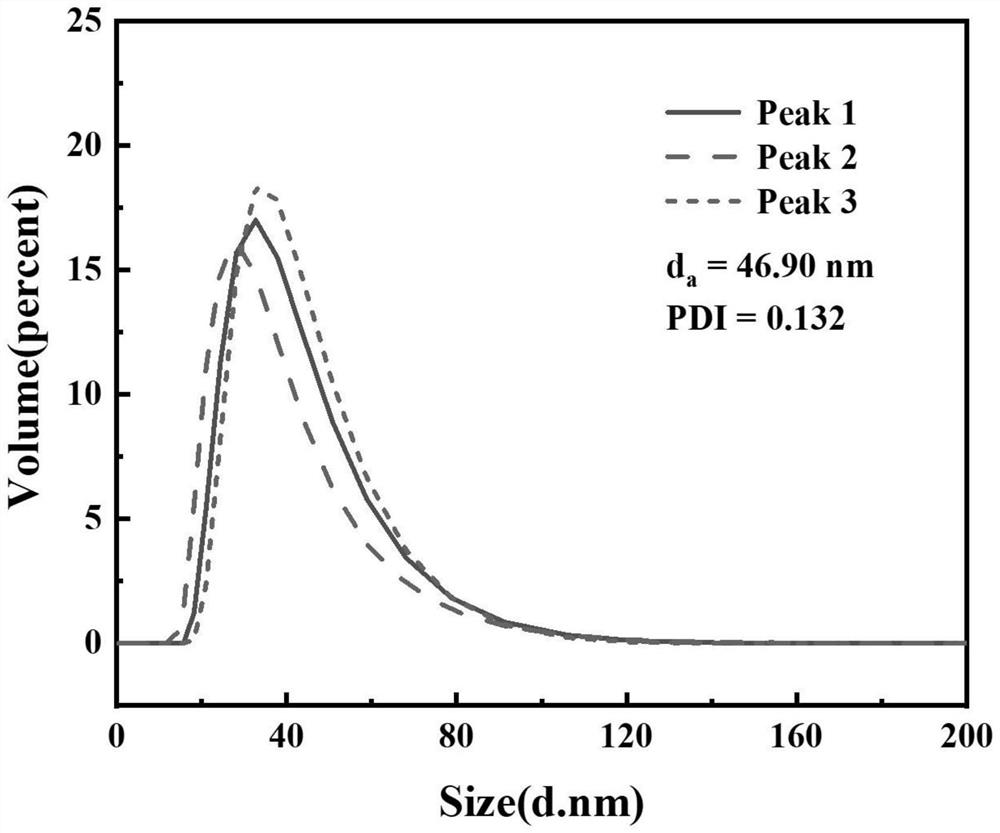

[0040]Step 1: Add 10g of sodium zirconium phosphate silver-loaded antibacterial agent, 300g of grinding balls with a particle size of 0.3mm, and 100mL of deionized water into the ball mill, and use the grinding balls with an average particle size of 0.3mm as the ball milling medium, water and ball milling medium The volume rat...

Embodiment 2

[0047] This embodiment is basically the same as Embodiment 1, and the special features are:

[0048] In this embodiment, a preparation method of the high-transparency antibacterial coating includes the following steps:

[0049] Step 1: Add 10g of sodium zirconium phosphate silver-loaded antibacterial agent, 300g of grinding balls with a particle size of 0.3mm, and 100mL of absolute ethanol into the ball mill. The volume ratio was 1:1, ball milled at 2000 rpm for 3 hours, and the grinding balls were removed by filtration to obtain an antibacterial agent dispersion containing 10 wt % of sodium zirconium phosphate-supported silver antibacterial agent. diameter less than 100nm; spare;

[0050] Step 2: Mix 10 mL of the antibacterial agent dispersion prepared in the first step, 20 mL of water-based polyurethane resin, and 70 mL of deionized water, mechanically stir for 30 minutes, fully stir and mix to obtain an antibacterial coating slurry;

[0051] Step 3: Use a 25 μm scraper to...

Embodiment 3

[0054] This embodiment is basically the same as the above-mentioned embodiment, and the special features are:

[0055] In this embodiment, a preparation method of the high-transparency antibacterial coating includes the following steps:

[0056] Step 1: Add 5g sodium zirconium phosphate silver-loaded antibacterial agent, 300g grinding balls with a particle size of 0.3mm, and 100mL deionized water into the ball mill, and use the grinding balls with an average particle size of 0.3mm as the ball milling medium, water and ball milling medium The volume ratio was 1:1, ball milled at 2000 rpm for 24 hours, and the grinding balls were removed by filtration to obtain an antibacterial agent dispersion containing 5wt% of sodium zirconium phosphate-supported silver antibacterial agent. diameter less than 100nm; spare;

[0057] Step 2: Mix 20 mL of the antibacterial agent dispersion prepared in the first step, 20 mL of water-based polyurethane resin, and 60 mL of deionized water, stir me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com