Dust suppression material as well as preparation method and application thereof

A cementitious material and formula technology, applied in chemical instruments and methods, dust prevention, mining equipment, etc., can solve the problem that dust suppression materials cannot meet the requirements of mine dust content, and achieve high strength, strong wind erosion resistance, and hydrophilicity. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

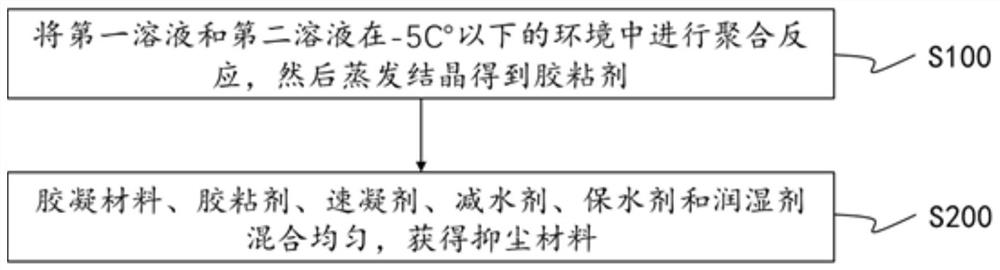

[0055] The embodiment of the present invention also provides a method for preparing a dust suppression material, which adopts the following steps:

[0056] Step S100, the first solution and the second solution are polymerized in an environment below -5°C, and then evaporated and crystallized to obtain an adhesive, wherein the first solution is epoxy resin, silane coupling agent, cellulose and starch glue. One of the aqueous solutions, the second solution is one of the aqueous solutions of polyvinyl chloride resin, asphalt, rubber binder, and vinyl acetate; the silane coupling agent is one of KH-550, KH-580, and KH-560. kind. The mass fraction of the first solution and the second solution is (10-30): (70-90).

[0057] In step S200, the gelling material, the adhesive, the accelerator, the water reducing agent, the water retaining agent and the wetting agent are mixed uniformly to obtain a dust suppression material.

[0058] The above-mentioned dust suppression materials are no...

Embodiment 1

[0066] By weight, 75 parts of Portland cement, 20 parts of adhesive, 5 parts of sodium metaaluminate, 3 parts of polycarboxylate water reducer, 6 parts of hydroxypropyl methylcellulose ether (400,000 mPa.s), 5 parts hydroxypropyl starch ether, 32 parts wetting agent. Put them into a mixer in turn and evenly stir and mix for 3 hours to obtain a dust suppression material.

[0067] The adhesive is obtained by evaporating and crystallizing the epoxy resin and the rubber adhesive after the completion of the polymerization reaction at -11.3 °C, and the mass ratio of the epoxy resin and the rubber adhesive is 30:70.

[0068] The wetting agent is a compound of sodium dodecylbenzenesulfonate and sodium dodecyl sulfate, and the mass ratio of sodium dodecylbenzenesulfonate and sodium dodecyl sulfate is 1:1.

Embodiment 2

[0070] By weight, 83 parts of sulfoaluminate cement, 34 parts of adhesive, 7 parts of sodium metaaluminate, 4 parts of polycarboxylate water reducer, 8 parts of hydroxypropyl methylcellulose ether (200,000 mPa.s) , 4 parts of hydroxypropyl starch ether, 40 parts of wetting agent. Put them into a mixer in turn and evenly stir and mix for 3 hours to obtain a dust suppression material.

[0071] The adhesive is obtained by evaporating and crystallizing the silane coupling agent and the polyvinyl chloride resin after the completion of the polymerization reaction at -11.3°C, and the mass ratio of the silane coupling agent and the polyvinyl chloride resin is 19.9:81.1.

[0072] The wetting agent is a compound of Tween 60 and Tween 80, and the mass ratio of Tween 60 and Tween 80 is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com