Waterproof locking resistance reducing agent for unconventional oil and gas reservoir fracturing, preparation method and application

A technology for oil and gas reservoirs and drag reducing agents, which is applied in the field of fracturing fluids and can solve the problems of fast polymer polymerization rate and insufficient molecular weight to meet the requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

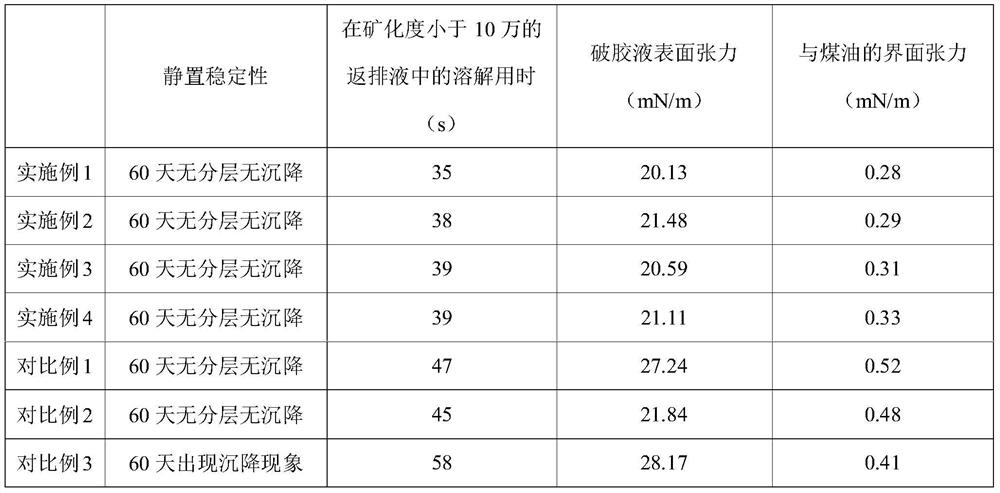

Examples

preparation example Construction

[0040] The preparation method of the above resistance reducing agent includes:

[0041] 1) Mix the white oil and organic montmorillonite of the formula, and stir until the viscosity of the mixture is uniform and stable;

[0042] 2) Add the surfactant, clay stabilizer and oxygen scavenger in the formula amount until fully dissolved;

[0043] 3) Add the polymer emulsion in the formula amount, and mix evenly to obtain the drag reducing agent.

[0044] Further, the process of the step 1) is: placing the white oil of the formula amount in the reaction kettle, warming up to 50~55 ℃, adding the organic montmorillonite of the formula amount, and the stirring rate is 1000~1200r / min, to The viscosity of the mixture is uniform and stable;

[0045] The process of the step 2) is as follows: the temperature in the kettle is lowered to 40-45° C., the stirring rate is 400-450 r / min, and the formula amount of surfactant, clay stabilizer and oxygen scavenger is added to fully dissolve;

[00...

Embodiment 1

[0054] 1) get 50kg of methacrylic acid-2-ethylhexyl and be dissolved in ethylene glycol to obtain solution A;

[0055] 2) get 6kg cyclohexanone peroxide and 6kg N, N-dimethylaniline is dissolved in ethylene glycol to obtain solution B;

[0056] 3) adding solution B at a uniform speed while stirring solution A to ensure uniform mixing to obtain a polymer emulsion;

[0057] 4) get 5# white oil 50kg and place in the reactor;

[0058] 6) The temperature in the reactor was raised to 55°C, 1.5kg of organic montmorillonite was added, and the stirring speed was controlled to be 1000r / min after the addition, until the viscosity of the mixture was uniform and stable;

[0059] 7) temperature in the reactor is down to 40 ℃, stirring speed is down to 400r / min, add 3.5kg surfactant (1.75kg sodium dodecylbenzene sulfonate mixes with 1.75kg dodecylamine acetate), 2kg Clay stabilizer and 1kg of oxygen scavenger until fully dissolved;

[0060] 8) Increase the temperature in the reaction kett...

Embodiment 2

[0062] 1) get 50kg of methacrylic acid-2-ethylhexyl and be dissolved in ethylene glycol to obtain solution A;

[0063] 2) get 7.5kg of cyclohexanone peroxide and 7.5kg of N, N-dimethylaniline and be dissolved in ethylene glycol to obtain solution B;

[0064] 3) adding solution B at a uniform speed while stirring solution A to ensure uniform mixing to obtain a polymer emulsion;

[0065] 4) Get 40kg of 5# white oil and place it in the reactor;

[0066] 6) The temperature in the reactor was raised to 50°C, 0.5kg of organic montmorillonite was added, and the stirring speed was controlled to be 1100r / min after the addition, until the viscosity of the mixture was uniform and stable;

[0067] 7) temperature in the reactor is reduced to 40 ℃, stirring speed is reduced to 450r / min, 2.5kg surfactant (1.25kg sodium dodecylbenzene sulfonate is mixed with 1.25kg dodecylamine acetate), 1.5 kg are added. kg of clay stabilizer and 0.6kg of oxygen scavenger until fully dissolved;

[0068] 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mana absorption | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| mana absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com