Composite soil passivator and preparation method thereof

A passivating agent and composite technology, which is applied in chemical instruments and methods, soil conditioning materials, fertilizer mixtures, etc., can solve the problem of difficulty in guaranteeing the long-term effectiveness of passivating agents, and achieves improved practicability and work effect, and increased fertility. degree, the effect of improving the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

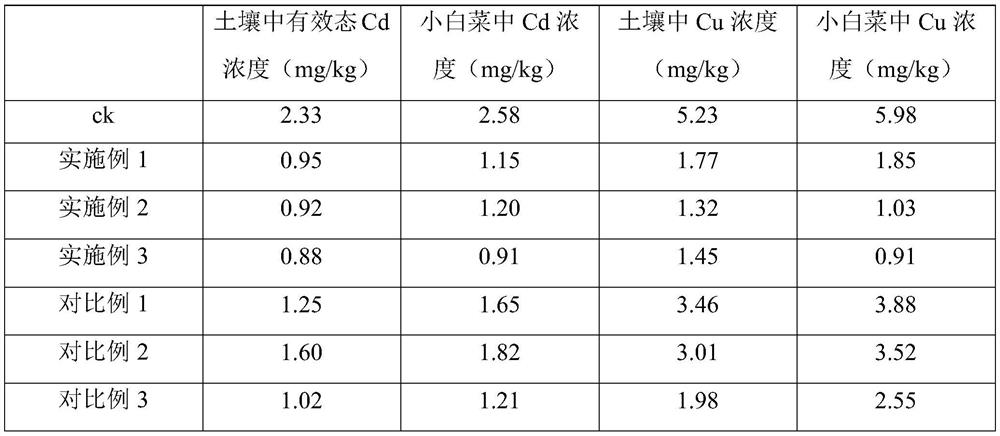

Examples

preparation example Construction

[0034] The present invention also provides a preparation method of the composite soil passivating agent, comprising the following steps:

[0035] (1) take respectively the blast furnace slag, biological matrix, sepiolite of weight portion and pulverize to particle diameter less than 50 μm for subsequent use;

[0036] (2) Add the crushed raw materials and sodium metasilicate pentahydrate into water, stir at 1000-5000rpm for 20-60min, then add microbial inoculants and nutrients, and stir at 1000-5000rpm for 20-60min;

[0037] (3) adding a pH adjusting agent to the uniformly mixed raw materials, and adjusting the pH to 7.2-7.6 to obtain the preparation.

Embodiment 1

[0040] The present embodiment provides a composite soil passivating agent, comprising the following components in parts by weight:

[0041] 100 parts of water, 8 parts of blast furnace slag, 4 parts of microbial inoculants (including 1 part of Aspergillus niger, Pseudomonas nitrogen-producing bacteria, 2 parts of biomass charcoal-based inoculants), 20 parts of biological substrate, 5 parts of nutrients, sea foam 6 parts of stone, 15 parts of sodium metasilicate pentahydrate and 10 parts of pH adjuster;

[0042] The nutrients include: 50 parts of peptone, 40 parts of agar, 10 parts of brown sugar and 5 parts of chitosan.

[0043] Also provided is a preparation method of the composite soil passivating agent, comprising the following steps:

[0044] (1) Pulverize the dried straws into particles with a diameter of 1 mm, pyrolyze them anaerobic for 1 hour at 300°C, pulverize again, and pass through a 200-mesh sieve to obtain a biological matrix;

[0045] (2) the quicklime of 10g an...

Embodiment 2

[0050] The present embodiment provides a composite soil passivating agent, comprising the following components in parts by weight:

[0051] 90 parts of water, 5 parts of blast furnace slag, 2.5 parts of microbial inoculum, 15 parts of biological matrix, 3 parts of nutrient, 5 parts of sepiolite, 10 parts of sodium metasilicate pentahydrate and 6 parts of pH adjuster;

[0052] The microbial inoculants include: 15 parts of Aspergillus niger, 15 parts of Pseudomonas nitrogen-producing and 60 parts of biomass charcoal-based inoculants;

[0053] The nutrients include: 70 parts of peptone, 40 parts of agar, 10 parts of brown sugar and 8 parts of chitosan.

[0054] Also provided is a preparation method of the composite soil passivating agent, comprising the following steps:

[0055] (1) Pulverize the dried straws into particles with a diameter of 5 mm, pyrolyze them anaerobic for 2 hours at 450°C, pulverize again, and pass through a 100-mesh sieve to obtain a biological matrix;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com