Oxygen-increasing phosphorus-free cleaning paste and preparation method thereof

A cleaning paste, self-adaptive technology, applied in the direction of chemical instruments and methods, inorganic/element cleaning composition, organic/inorganic compound composition, etc., can solve the problem of limited grinding capacity of stirring and grinding equipment, dispersion and emulsification of cleaning paste formula Incompetence and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

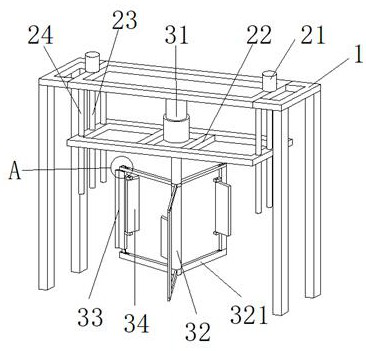

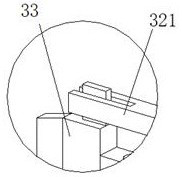

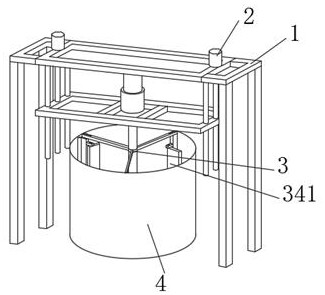

[0046] like Figure 1-3 As shown, the present embodiment provides a kind of oxygen-enhancing phosphorus-free cleaning paste, including the following raw materials by weight: 4 parts of sodium percarbonate, 3 parts of sodium perborate, 5 parts of potassium carbonate, 28 parts of sodium bicarbonate, 6 parts of sodium carbonate , 1 part of sodium carboxymethyl cellulose, 18.2 parts of active substances, 0.1 part of essence, 5 parts of whitening antifreeze agent, and the rest are purified water.

[0047] Actives include 2 parts of dodecyl betaine, 0.2 parts of alkylphenol polyoxyethylene ether, 6 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 8 parts of linear alkyl benzene sulfonate sodium, and 2 parts of alkyl alcohol amide .

[0048] The whitening antifreeze is a saturated edible sodium chloride solution.

[0049] Stirring by an adaptive stirring system, including the following steps:

[0050] SA: 4 parts of quasi-sodium percarbonate, 3 parts of sodium perborat...

Embodiment 2

[0069] The difference between this embodiment and Embodiment 1 is that this embodiment provides an oxygen-enhancing and phosphorus-free cleaning paste, which includes the following raw materials by weight: 5 parts of sodium percarbonate, 4 parts of sodium perborate, 6 parts of potassium carbonate, and 6 parts of hydrogen carbonate. 29 parts of sodium, 7 parts of sodium carbonate, 1.3 parts of sodium carboxymethyl cellulose, 20 parts of active substances, 0.15 parts of essence, 6 parts of whitening antifreeze, and the rest are purified water.

[0070] Actives include 2.5 parts of dodecyl betaine, 2.5 parts of alkylphenol polyoxyethylene ether, 7 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 9 parts of linear alkyl benzene sulfonate sodium, and 2.5 parts of alkyl alcohol amide .

[0071] The whitening antifreeze is a saturated edible sodium chloride solution.

[0072] Stirring by an adaptive stirring system, including the following steps:

[0073] SA: 5 parts of...

Embodiment 3

[0089] The difference between this embodiment and Embodiment 1 is: this embodiment provides an oxygen-enhancing and phosphorus-free cleaning paste, which includes the following raw materials by weight: 6 parts of sodium percarbonate, 5 parts of sodium perborate, 7 parts of potassium carbonate, and 7 parts of hydrogen carbonate. 30 parts of sodium, 8 parts of sodium carbonate, 1.5 parts of sodium carboxymethyl cellulose, 24.3 parts of active substances, 0.2 parts of essence and 7 parts of whitening and antifreeze agent, and the rest are purified water.

[0090] The active substances include parts of dodecyl betaine, 0.3 parts of alkylphenol polyoxyethylene ether, 8 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 10 parts of linear alkyl benzene sulfonate sodium, and 3 parts of alkyl alcohol amide.

[0091] The whitening antifreeze is a saturated edible sodium chloride solution.

[0092] Stirring by an adaptive stirring system, including the following steps:

[009...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com