Bacterial strain for degrading thiocyanate, composite bacterial strain, microbial inoculum and application of bacterial strain, composite bacterial strain and microbial inoculum

A technology of thiocyanate and thiocyanic acid, which is applied in the direction of microorganism-based methods, bacteria, biological water/sewage treatment, etc., can solve the problems of inability to meet market demand, low degradation ability of single bacteria, high treatment cost, etc., and achieve The effect of shortening the degradation cycle, stable operation and high degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

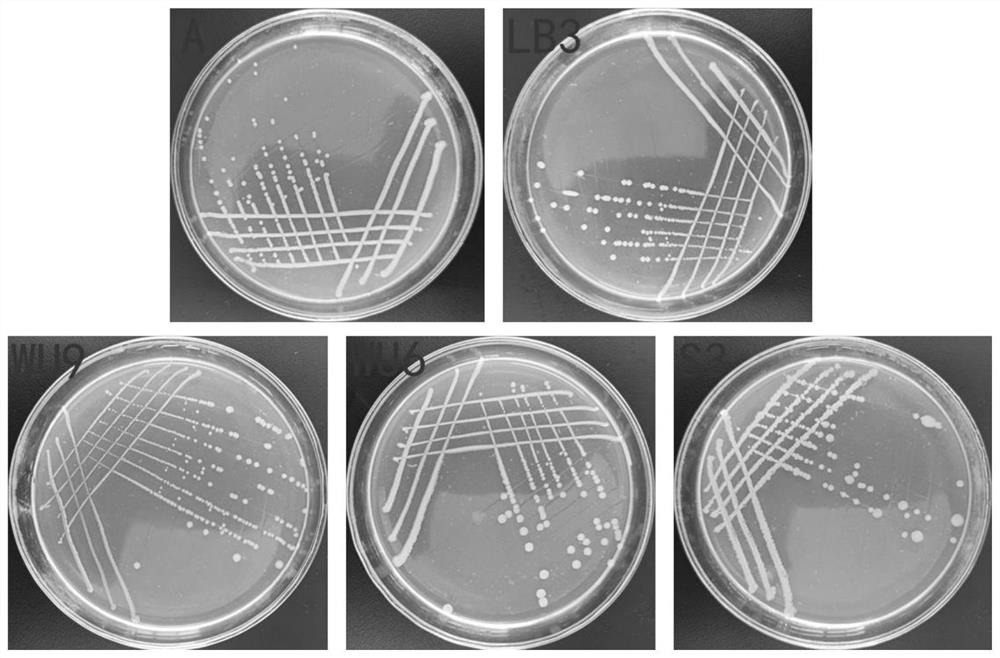

[0038] This embodiment is the screening process of Lysinibacillus sp.S3, Acinetobacter seifertii LB3, Thiobacillus sp.A, Pseudomonas sp.WU6 and Acinetobacter baylyi WU9, specifically including:

[0039] The industrial wastewater containing thiocyanate (from Jiangxi Fengcheng Xingao Coking Co., Ltd.) was screened with a medium containing thiocyanate as the only carbon source, and 5 strains were obtained by screening, which were recorded as S3, LB3, A. WU6 and WU9;

[0040] The 5 strains obtained above were classified and identified by 16srDNA gene sequencing method, wherein the gene sequence of A is shown in SEQ ID NO: 1, and the details are as follows:

[0041]ATTGAACGCTGGCGGAATGCTCCACACATGCAAGTCGAACGGCAGCACGGGAGCTTGCTCCTGGTGGCGAGTGGCGAACGGGTGAGTAATGCGTCGGAACGTGCCGAGTAATGGGGGATAACGCGGCGAAAGTCGCGCTAATACCGCATACGCCCTGAGGGGGAAAGCGGGGGATCGCAAGACCTCGCGCCATTCGAGCGGAAGACGTCTGATTAGCTAGTTGGTGGGGTAAAGGCCCACCAAGGCGACGATCAGTAGCGGGTCTGAGAGGATGATCCGCCACACTGGGACTGAGACACGGCAAAGACTCCTACGGGAGGCA...

Embodiment 2

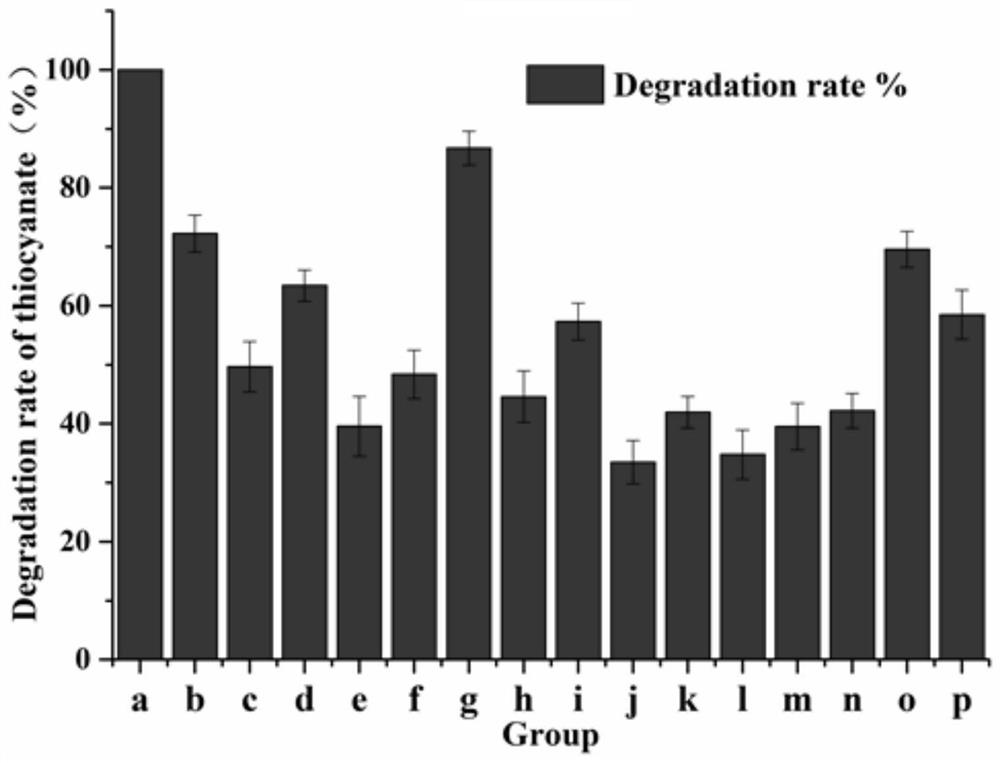

[0052] This embodiment is a composite strain for degrading thiocyanate, the composite strain includes Lysinibacillus sp.S3, Acinetobacter seifertii LB3, Thiobacillus sp.A, Pseudomonas sp. .WU6, Acinetobacter baylyi WU9;

[0053] Among them, the deposit number of Lysinibacillus sp.S3 in the China Collection of Type Cultures is CCTCC NO: M2022214, the deposit number of Acinetobacter seifertii LB3 in the China Collection of Type Cultures is CCTCC NO: M2022215, and the deposit number of Thiobacillus sp.A in the China Type Culture Collection The deposit number of the center is CCTCCNO: M2022216, the deposit number of Pseudomonas sp.WU6 at the China Center for Type Culture Collection is CCTCC NO: M2022217, and the deposit number of Acinetobacter baylyi WU9 at the China Center for Type Culture Collection is CCTCC NO: M2022218;

[0054] The mass ratio of Lysinibacillus sp.S3, Acinetobacter seifertii LB3, Thiobacillus sp.A, Pseudomonas sp.WU6 and Acinetobacter baylyi WU9 in the composi...

Embodiment 3

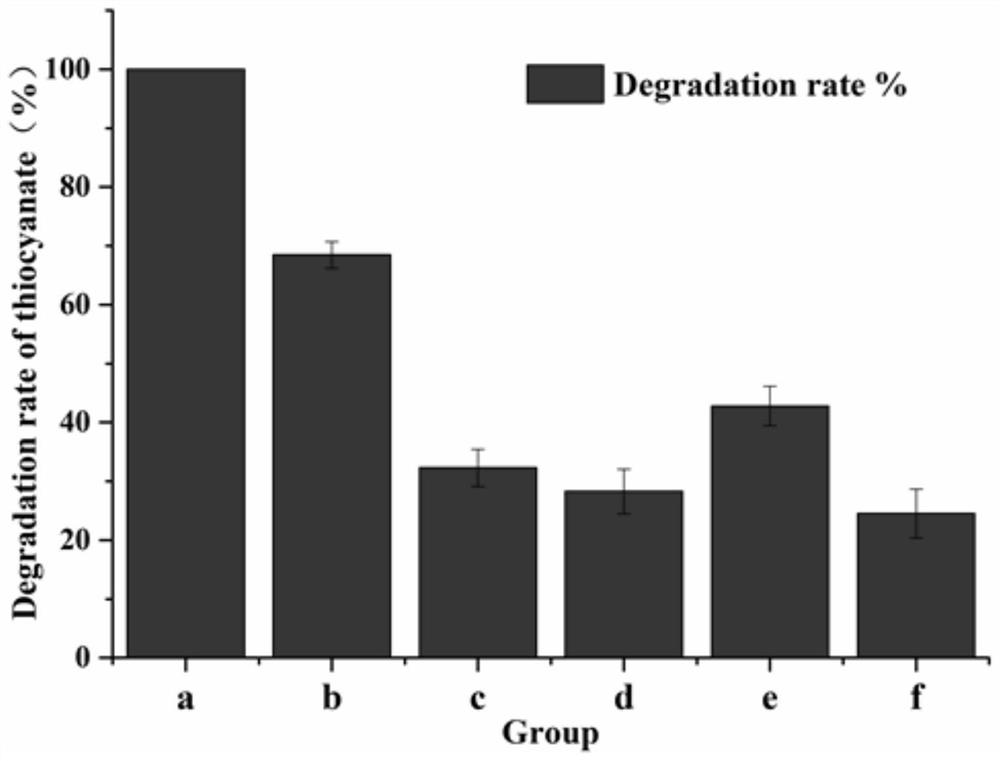

[0056] The present embodiment is a degradation method of thiocyanate in thiocyanate-containing waste water, and the degradation method comprises the following steps:

[0057] (a) preparation of embodiment 1 compound strain:

[0058] Each strain was inoculated into the LB medium for activation, and then expanded and cultured. Then, the culture medium of the expanded culture was centrifuged at 8000 r / min at 4°C, and the culture medium was removed, rinsed with physiological saline, and centrifuged to obtain each bacterial cell;

[0059] Each bacterial body is dried at room temperature, and each bacterial species is mixed according to the mass ratio to obtain a composite strain;

[0060] (b) According to the inoculation amount of 6g / L, inoculate the composite strain into the wastewater containing thiocyanate to degrade thiocyanate for 36h, wherein, the temperature of the wastewater is controlled to be 28~35°C, and the dissolved oxygen content is 2~35°C. 5mg / L, pH value is 6.7~7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com